Suzhou Jinyicheng Thread&Ribbon Co.,Ltd |

|

Verified Suppliers

|

|

Product Features | ||

Product Name | White Polyester Knitted Elastic Band Wholesale | |

Material | Polyester & Rubber | |

Tenchnic | Woven | |

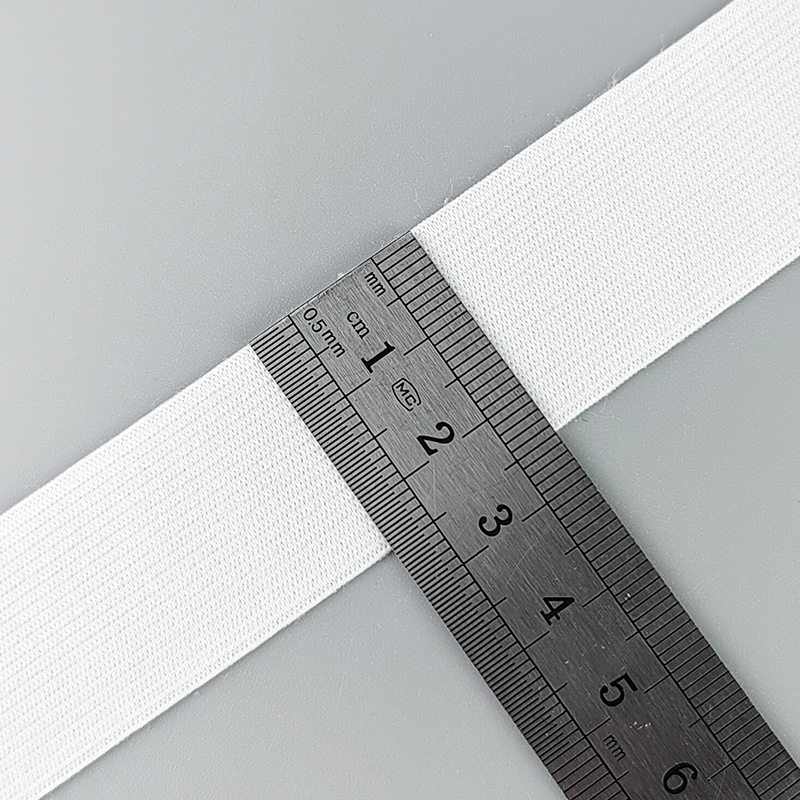

Width | 1-10cm or as your request | |

Thickness | 1.0-1.2mm or as your request | |

Feature | Double faced | |

Color | Various colors | |

MOQ | 3,000Y | |

Usage | Garment, home textile, underwear, bag ,belt, wrist band, etc. | |

Package | 1.Usually 50-100Y/Roll; 2.3,000-5,000Y/Carton 3.As your requirements | |

Payment | T/T 30% in advance, the balance paid against the B/L Copy or 100%

L/C at sight. | |

Delivery Time | About 20-30 days (depending on the order qty) | |

Shipment | By express (DHL, EMS, TNT,UPS, FEDEX)/by sea/air, etc. | |

FOB PORT | Shanghai,China | |

Quality Certification | Oeko-Tex & CQC | |

After-sales Service | We value after-sales service, we promise repairing, replacing and

refunding if there’s any quality problem of our products | |

The production process of knitted elastic involves several steps. Here is a general overview of the process:

Yarn Selection: The first step is to select the appropriate yarn for the knitted elastic. The yarn can be made from various materials such as cotton, polyester, nylon, or a blend of different fibers. The choice of yarn depends on the desired properties of the elastic, such as stretchability, durability, and comfort.

Knitting: The selected yarn is fed into a knitting machine, which is specially designed for producing elastic fabrics. The knitting machine uses needles or hooks to form loops and interlock the yarn to create a knitted structure. The knitting process can be done on a flat knitting machine or a circular knitting machine, depending on the desired width and construction of the elastic.

Elastic Insertion: In some cases, an elastic material, such as rubber or spandex, is inserted into the knitted fabric during the knitting process. This elastic material provides the stretchability and recovery properties to the knitted elastic. The elastic material is typically fed into the knitting machine along with the yarn, and the machine incorporates it into the fabric structure.

Finishing: Once the knitting process is complete, the knitted elastic fabric undergoes various finishing treatments. This may include processes such as dyeing, heat setting, or coating to enhance the appearance, colorfastness, and durability of the elastic. Finishing treatments can also help to improve the elasticity and recovery properties of the fabric.

Cutting and Packaging: After the finishing process, the knitted elastic fabric is cut into the desired widths and lengths. The elastic may be cut into individual strips or kept in continuous rolls, depending on the intended application. The cut elastic is then packaged and prepared for distribution or further manufacturing processes.

It's important to note that the specific production process for knitted elastic may vary depending on the manufacturer, equipment used, and the desired characteristics of the elastic. Additionally, specialized machinery and techniques may be employed to create specific patterns or designs in the knitted elastic.