Chengdu Yuanjin Environmental Engineering Co., Ltd. |

|

Verified Suppliers

|

|

1.0m3/h RO EDI Softened Water Plant for Deionized Water

RO EDI WATER PLANT DESCRIPTION

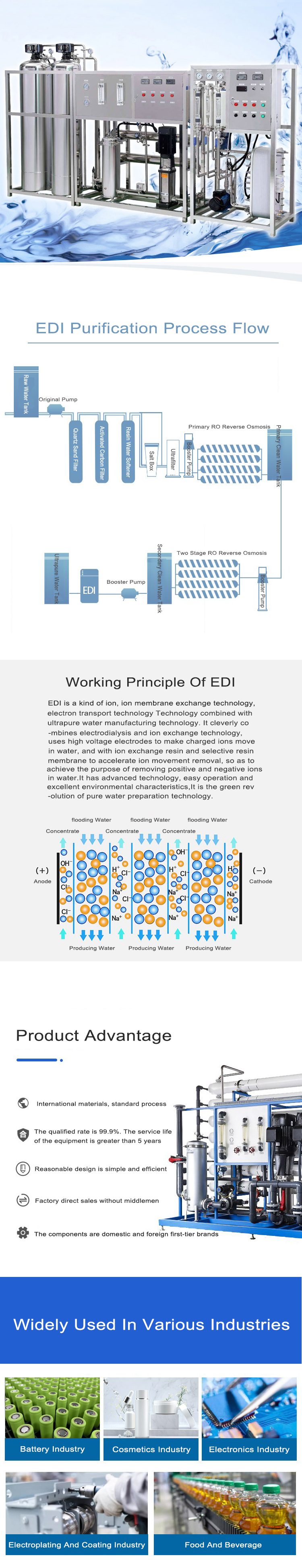

RO+EDI ultra pure water treatment equipment uses pre-treatment, reverse osmosis technology, ultra purification treatment, and post treatment methods to almost completely remove the conductive medium in the water, while also removing non dissociative colloidal substances, gases, and organic substances in the water to a very low degree.

EDI (Electrodeionization) is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology, and ion electromigration technology. It cleverly combines electrodialysis and ion exchange technology, utilizing high voltage at both ends of the electrodes to move charged ions in water, and cooperates with ion exchange resins and selective resin membranes to accelerate ion removal, thus achieving the goal of water purification.

In the EDI desalination process, ions are removed through ion exchange membranes under the action of an electric field. At the same time, water molecules generate hydrogen ions and hydroxide ions under the action of an electric field, which continuously regenerate the ion exchange resin to maintain its optimal state.

The equipment has the advantages of compact structure, small area, high unit water production, less energy consumption, thorough removal of impurities, wide range of use, high degree of automation, easy to use and operation, no pollution and so on.

Pure Water Requirements For Various Industries

| Industry Type | Use | Water Quality Requirement |

| Hardware electroplating factory | Production of plating parts rinse with pure water | Resistivity≤10~20μs/cm |

| Plastic electroplating factory | Production of plating parts rinse water | Resistivity≤10μs/cm |

| Metal plastic gold plated silver | Production of plating parts rinse water | Resistivity≤2μs/cm |

| Circuit board factory | Microetching rinse pure water | Resistivity≤10μs/cm |

| Electronics, electric appliance factory | Pure water for industrial use | Resistivity≥2MΩ.CM |

| Glass shell production plant | Glass shell production rinse water | Resistivity≥2MΩ.CM |

| Aluminum alloy production plant | Pure water for coating rinse | Resistivity≥2MΩ.CM |

| Precision hardware components factory | Surface treatment rinse with pure water | Resistivity≥5MΩ.CM |

| Car paint factory | Pure water for washing painted surface | Resistivity≥5MΩ.CM |

| Dyeing factory | Printing and dyeing with pure water | Resistivity≥2MΩ.CM |

| Nimh battery, electronics factory | Ultrapure water for industrial use | Resistivity≥10MΩ.CM |

| Color display production plant | Rinse the picture tube with ultrapure water | Resistivity≥18MΩ.CM |

| The computer factory | Hard disk production rinse ultrapure water | Resistivity≥18MΩ.CM |

| Laboratory use | Electron-grade ultrapure water | Resistivity≥18MΩ.CM |

| Coating glass factory | Electronic ultrapure water for film plating | Resistivity≥17~18MΩ.CM |

| Float glass factory | Ultrapure water for coating industry | Resistivity≥17MΩ.CM |

| Semiconductor factory | Ultrapure water for production | Resistivity≥15MΩ.CM |

| Liquid crystal display plant | Ultrapure water for LCD flushing | Resistivity≥12~15MΩ.CM |

EDI technology has the following advantages compared to mixed ion exchange technology:

① Stable water quality

② Easy to achieve fully automatic control

③ Will not shut down due to regeneration

④ No need for chemical regeneration

⑤ Low operating costs

⑥ Small factory area

⑦ No sewage discharge

Scope Of Application

◆ Cosmetics Industry

Pure water for skin care products, shampoo, hair dye, toothpaste, and hand sanitizer

◆ Food, Beverage, Purified Water Industry

The production of water for food and beverage production as well as pure water

◆ Electronics Industry

Aluminum foil cleaning; Vacuum tube spraying liquid dispensing; Clear tube glass shell cleaning, precipitation, wetting, film washing, tube neck cleaning; Liquid crystal screen surface cleaning and preparation: transistor and integrated circuit silicon wafer cleaning water, preparation water.

◆ Battery Industry

Pure water for battery production, pure water for lithium battery production, and pure water for solar cell production

Pure water for concrete admixture preparation

High purity water for glass coating, glass products cleaning water, lamp cleaning water

◆ Textile Printing And Dyeing Industry

Pure water for printing and dyeing auxiliary preparation, pure water for wipes, and pure water for facial masks

◆ Pure Water For Ultrasonic Cleaning

◆ Coating Industry

coating preparation with pure water, electroplating preparation cleaning water, electrophoresis paint preparation cleaning water

DETAILS

Production Workshop