Zhangjiagang City Bievo Machinery Co., Ltd. |

|

Verified Suppliers

|

|

16000BPH High Speed Automatic 3 In 1CSD Carbonated Beverage Soda Sparkling Water Soft Drinks Filling Machine

| Technical Parameters Of Auto Carbonated Soda Water Filling Machine : | |||||

Model (BCGF) | 18/18/6 | 24/24/6 | 32/32/8 | 40/40/12 | 50/50/12 |

Washing heads | 18 | 24 | 32 | 40 | 50 |

Filling heads | 18 | 24 | 32 | 40 | 50 |

Capping heads | 6 | 6 | 8 | 12 | 12 |

Capacity (BPH) | 3500 | 5000 | 8000 | 12000 | 16000 |

Power(kw) | 3.5 | 4.5 | 6 | 7.5 | 9.5 |

Dimension (mm) | 2600*1920 | 3100*2300 | 3800*2500 | 4600*2800 | 5450*3300 |

| *2550 | *2800 | *2900 | *2900 | *2900 | |

Weight(kg) | 3500 | 4500 | 5600 | 8500 | 9800 |

Machines Details Of Automatic Carbonated Soda Water Filling Machine:

3 IN 1 Carbonated Soft Drinks Filling Machine

Out Look:

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever

antirust

> All seal where liquid may Leakage & base neck come with

rubber, water proof

> Manual lubrication system

Washing Part:

l. The rotary wheel is a fully stainless steel welded structure.

2. The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips

bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle

clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

3. The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall,

and also saves rinsing water.

4. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

5. The rinser is driven by driving system positioned inside machine frame via gear transmission.

6. Transfer starwheel

7. Made of stainless steel of superior quality.

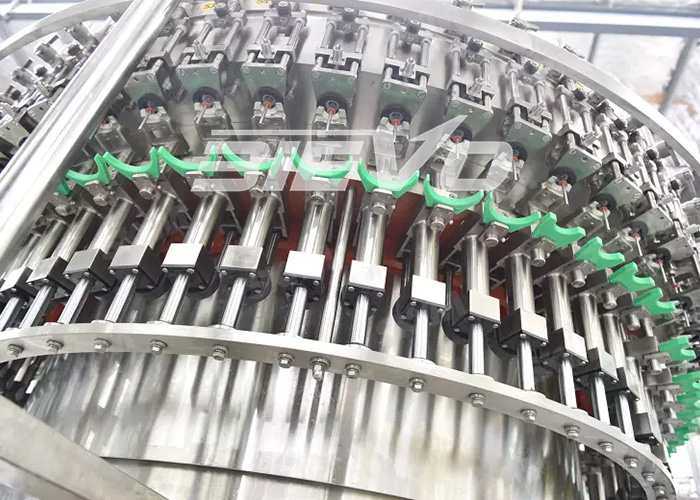

l. Rotary wheel fully made of stainless steel SUS 304.

2. Gravity filling method.

3. Filling valves are made of SUS316L.

4. Filling valves are reasonably structured with accurate filling.

5. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

6. Level of cylinder is controlled with float-ball.

7. Filler is driven through gears inside the machine frame.

Capper is the machine with highest precision, influence very much with the stability and reliability of the filling monoblock.

Our capper features as follows:

l.The equipment is designed with the support of experts from school of engineering and mechanical in Shanghai Jiao

Tong University, and uses the technology of Arol from Italy, most advance technology in the world, developed with the

experience of asepsis filling machine. For example,

1) extruding wheel (main part to control the stability when sealing), uses the technology of Arol. Kinematical and kinetic

design of the wheel by experts improves the stability and credibility of the equipment.

2) Sealing faucet (main part to control the credibility of sealing), is improved by experts with the design of alnico. Besides

the magnetic contortion variation device, there is variation dial which makes variation more easily. The benefit of this design is not only it can set the contortion, but also it makes contortion more precise and credible, and reduces inferior.

Electrical Brand List | |

AC Contactor | SIEMENS (GERMANY) |

Thermal overload relay | SIEMENS (GERMANY) |

PLC | SIEMENS (GERMANY) |

Touch Screen | SIEMENS (GERMANY) |

Converter | SIEMENS (GERMANY) |

Power Switch | SIEMENS (GERMANY) |

Intermediate Relay | SCHNEIDER (FRANCE) |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

Q1: Where is your factory? How can I visit there?

After-sales service:

We guarantee the quality of the main parts within 12 months.

If the main parts go wrong without artificial factors within one

year, we will freely provide them or maintain them for you.

After one year, if you need to change parts, we will kindly provide

you with the best price or maintain it in your site.

Whenever you have technical question in using it, we will freely do

our best to support you.

Guarantee of quality :

The Manufacturer shall guarantee the goods are made of

Manufacturer’s best materials, with first class workmanship,

brand new, unused and correspond in all respects with the quality,

specification and performance as stipulated in this

Contract.

Quality guarantee period is within 12 months from B/L date.

The Manufacturer would repair the contracted machines free of

charge during the quality guarantee period.

If the break-down can be due to the improper use or other reasons

by the Buyer, the Manufacturer will collect repair

parts cost.

Installation:

The seller would dispatch his engineers to instruct the

installation.

Cost would be bear on buyer’s side (round way flight tickets,

accommodation fees in buyer country).