Zhangjiagang City Bievo Machinery Co., Ltd. |

|

Verified Suppliers

|

|

7000BPH Carbonated drink bottling plant/ Filling Machine / soda energy soft drink filling machine

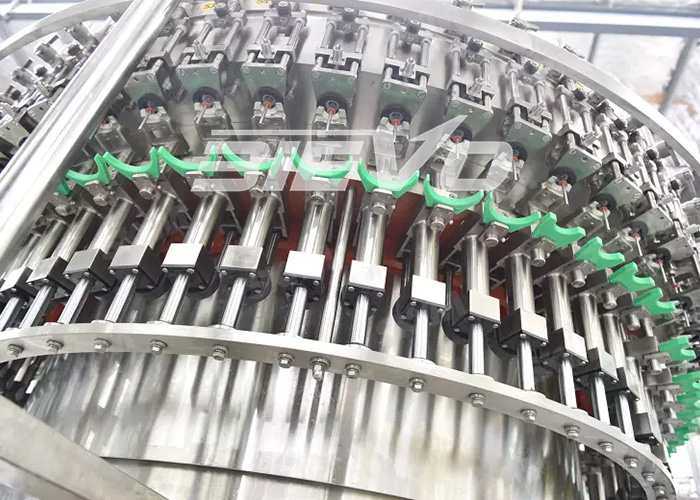

High Hygiene Rinsing

304/316 Stainless steel Gripper with plastic pad, ensure minimal

bottle crash during rinsing.

High precision valve

304/316 Stainless steel high precision filling nozzle.

Technical Parameters:

Model (BCGF) | 18/18/6 | 24/24/6 | 32/32/8 | 40/40/12 |

Washing heads | 18 | 24 | 32 | 40 |

Filling heads | 18 | 24 | 32 | 40 |

Capping heads | 6 | 6 | 8 | 12 |

Capacity (BPH) | 3500 | 5000 | 8000 | 12000 |

Power(kw) | 3.5 | 4.5 | 6 | 7.5 |

Dimension (mm) | 2600*1920 | 3100*2300 | 3800*2500 | 4600*2800 |

| *2550 | *2800 | *2900 | *2900 | |

Weight(kg) | 3500 | 4500 | 5600 | 8500 |

Machines Details :

3 IN 1 Carbonated Soft Drinks Filling Machine

Washing Part:

<1> All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<1> 304/316 Stainless steel high precision filling nozzle

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping <2> All 304/316 stainless steel construction <3> No bottle no capping <4> Automatic stop when lack of bottle

Beverage Mixer

Sprat tunnel

Electrical Brand List | |

AC Contactor | SIEMENS (GERMANY) |

Thermal overload relay | SIEMENS (GERMANY) |

PLC | SIEMENS (GERMANY) |

Touch Screen | SIEMENS (GERMANY) |

Converter | SIEMENS (GERMANY) |

Power Switch | SIEMENS (GERMANY) |

Intermediate Relay | SCHNEIDER (FRANCE) |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

1.Installation, debug After equipment reached the workshop of customer, place the equipment according to plane layout we offered.We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line.Time for installation and debug is 15-25 days. 2.Training Our company offer technology training to customer.The content of training is structure and maintenance of equipment, control and operation of equipment.Training is in the workshop of customer.Seasoned technician will guide and establish training outline.After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures. 3.Quality guarantee We promise that our goods are all new and not used.They're made of suitable material, adopt new design.The quality, specification and function all meet the demand of contract.We promise that the products of this line could storage for one year without adding any aseptic. 4.After sales (1)After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price.In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures.If you could not solve the problems, we will guide you by phone;If the problems are still can not solve, we will arrange technician to your factory solving the problems.The cost of technician arrangement you could see the cost treatment method of technician. (2)After quality guarantee, we offer technology support and after sales service.Offer wearing parts and other spare parts at favorable price;After quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures.If you could not solve the problems, we will guide you by phone;If the problems are still can not solve, we will arrange technician to your factory solving the problems.The cost of technician arrangement you could see the cost treatment method of technician.

Q1:What's your guarantee or the warranty of the quality if we buy your machines?

A1:We offer you high quality machines with 1 year guarantee . we will give u spare part free in 1 year,Life long after service. Mean while, our engineers go more than 50 countries for debugging, with rich experience.

Q2:When can I get my machine after I paid?

A2:We will deliver the machines on time as the date we agreed both side.

Q3:How can I install my machine when it arrives?

A3:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q4:What's the delivery time?

A4:30-45 days after the T/T deposit or L/C.

Q5:What's min order quantity?

A5:1 unit