Zhangjiagang City Bievo Machinery Co., Ltd. |

|

Verified Suppliers

|

|

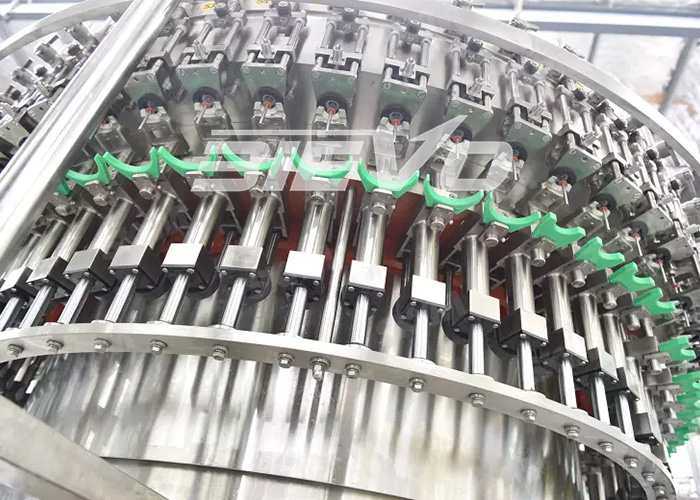

Beer glass bottle filling machine capping Manufacturer soda water making bottling Line

All parts which will contact beverages directly adopt SUS304 or

SUS316 stainless steels , all the surfaces of the machine accessory

will be polished till smooth enough for easily rinsing. The sealing

materials are EPDM rubber.

PLC controlled, and using electromagnetism valve to control liquid

level, keep all the bottles’ beverage level are same.

Adopt new type filling valves which are especially designed for

plastic bottles. The returned air and the liquid in filling tank

are insulated to ensure cleanliness of the filled beverages.

Adopt advanced magnet clutches for capping with adjustable

torsional moment to ensure capping safely and reliably.

1. Using the conveyor sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottle neck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed balanced pressure flow valve filling valve, filling fast, filling accurate and no liquid spit out.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON or ABB.

Technical Parameters Of Carbonated Soda Water Filling Machine :

Model (BCGF) | 24/24/6 | 32/32/8 | 40/40/12 |

Washing heads | 24 | 32 | 40 |

Filling heads | 24 | 32 | 40 |

Capping heads | 6 | 8 | 12 |

Capacity (BPH) | 5000 | 8000 | 12000 |

Power(kw) | 4.5 | 6 | 7.5 |

Dimension (mm) | 3100*2300 | 3800*2500 | 4600*2800 |

| *2800 | *2900 | *2900 | |

Weight(kg) | 4500 | 5600 | 8500 |

Machines Details :

3 IN 1 Carbonated Soft Drinks Filling Machine

Out Look:

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever

antirust

> All seal where liquid may Leakage & base neck come with

rubber, water proof

> Manual lubrication system

Washing Part:

- Into bottle way is air conveyor direct connection with bottle

dial.

- All 304/316 stainless steel rinse heads, water spray style inject

design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal

bottle crash during washing.

The three-in-one unit completes the three processes of bottle washing, filling and capping at one time, with little bottle wear, accurate and stable transmission, and convenient bottle type replacement. * The specially designed all-stainless steel bottle washer bottle clamp is sturdy and durable, and does not touch the threaded part of the bottle mouth to avoid secondary pollution of the bottle mouth. * High-speed and large-flow gravity filling valve, fast filling speed, accurate liquid level without liquid loss.

* All parts in contact with liquid are made of high-quality stainless steel materials or food-grade engineering plastics, which meet the national food hygiene standards. * The bottle bottom support plate of the bottle output wheel adopts a spiral descending method, and the height of the bottle conveyor chain is not required to change the bottle shape.

| Technical Partment Of Carbonated Soda Water Filling Machine | |||

S/N | Name | Brand | Country |

1 | Main motor | ABB | Switzerland |

2 | Inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- relay | SCHNEIDER | France |

7 | Air-break switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on. Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

After Sales Service

1. Find our products through www.newcrownmachinery.com

2. Two years warranty for the whole system

3. Free equipment installation and debugging

4. After 1 year, we can help you to maintain the machine and the accessories are provided only on the cost price

5. Every 3 years, we can help to overhaul the machine free (Labor)

6. We can provide internship service and help you train the operator and machines

7. Free production technology and process configuration

8. We can help you to design the production line, workshop and provide turn-key project