SHANGHAI DUBHE ENVIRONMENTAL PROTECTION&TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

Flat Plate Membrane Element for MBR: Anti-Pollution, High Porosity, Semi-Interpenetrating Network DEM-01

Introduction to Flat Plate Membrane Element

Introduction to Flat Plate Membrane ElementFlat Plate Membrane Element is one of the specialized membrane products for MBR membrane bioreactors.

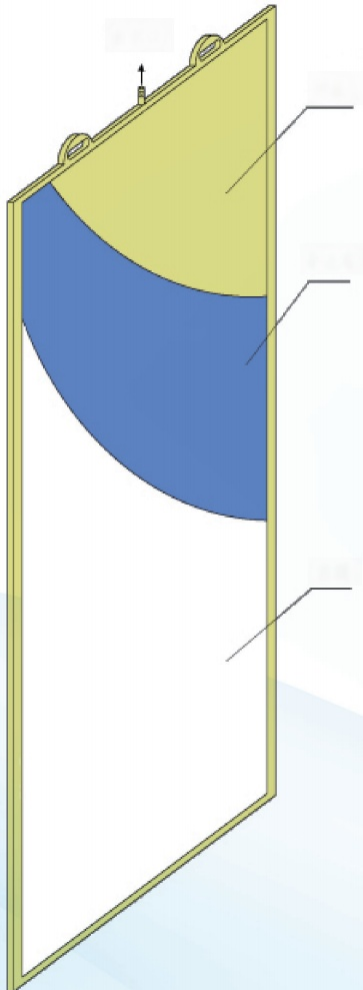

Working Principle of Flat Plate Membrane Element: The treated water after membrane filtration flows through the hydrophilic guide cloth, and is discharged from the water intake through the water-producing flow channel of the support plate.

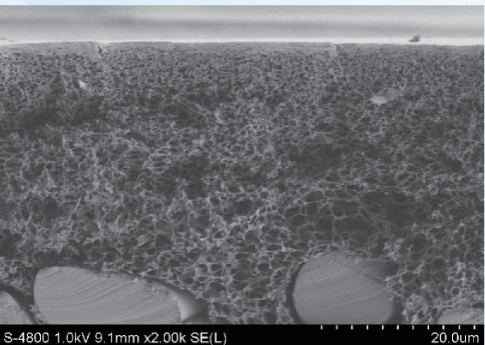

Finished Flat Membrane Elements Membrane Microstructure(inlaid type)

Construction Feature of the Flat Plate Membrane Element

Construction Feature of the Flat Plate Membrane ElementFlat plate membrane element structure: flat plate membrane element is made of ABS liner, hydrophilic infusion cloth and anti-pollution, inlay type.

1. The hydrophilic cortex, near-cortex and porous support layer gradually become a sponge-like dense and topological structure with higher porosity.

2. The strong capillary force reduces the membrane pore resistance and improves the filtration flux in the membrane application.

3. The separation layer and the support layer form a semi-interpenetrating network, which improves the adhesion fastness and blasting strength between layers and prolongs the service life and backwash tolerance.

Schematic Structure of Flat Membrane Elements

Material Advantage

Material Advantage1. Permanent hydrophilic properties enhance the anti-fouling properties of the separation membrane surface,

2. During the membrane filtration process, the attenuation rate of water production is reduced by more than 30%;

Better anti-pollution performance: It can maintain high-throughput and stable operation under higher activated sludge concentration, and has excellent anti-pollution performance.

3. Good mechanical stability: the high-strength diaphragm support will not tear, which can completely guarantee high-quality water.

4. High throughput, stable water production;

5. The cleaning method is more convenient, and the cleaning cycle is longer: bottom aeration combined with large air bubbles can effectively shear the diaphragm, and the cleaning cycle is long.

6. Long service life and low operating cost: the normal service life is 5-8 years, no need to replace the diaphragm frequently, and the unique design can be replaced one by one.

APPLICATION

APPLICATIONThe flat plate membrane element is widely used in membrane bioreactors (MBRs) for wastewater treatment. MBRs combine conventional activated sludge treatment with membrane filtration to achieve efficient solid-liquid separation and high-quality effluent.

1. Municipal sewage reuse.

2. Black and odorous water treatment.

3. Printing and dyeing wastewater treatment.

4. Chemical Wastewater Treatment.

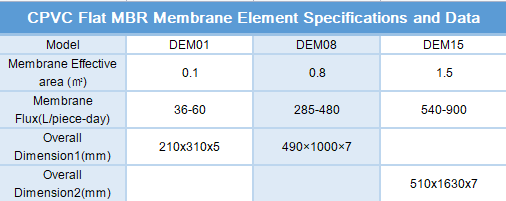

Technical Data & External Dimensions

Technical Data & External Dimensions

Remark:

1. The membrane flux in the table is the initial flux of a single membrane element when treating municipal wastewater at 25℃ and under vacuum.

2. When treating different water quality, users should conduct sufficient tests to determine the design value of membrane flux.

3. The membrane element use process is the vertical state, sewage is filtered by the membrane, through the gap between the liner and the guide cloth by the water pressure or negative pressure from the outlet, while the aeration pipe discharged bubbles on the surface of the MBR membrane is constantly flushing, so that the activated sludge or other suspended pollutants are not easy to be deposited on the surface of the membrane, to prolong the membrane cleaning cycle, to ensure that the membrane equipment for a long period of time to ensure the stability of the operation.

Q1: Can you print our logo on the outer package?

A: Yes, you can.

Q2: Can we visit your company and factory?

A: Sure, if you can visit the factory, we will have relevant personnel to explain the products to you.

Q3: Can you accept mixed batches of different products?

A: We can accept the mixing of different equipment.

Q4: Do you have an inspection report for the material?

A: We can provide you with the relative certificates.