Jiangsu Guonong Environmental Protection Co., Ltd. |

|

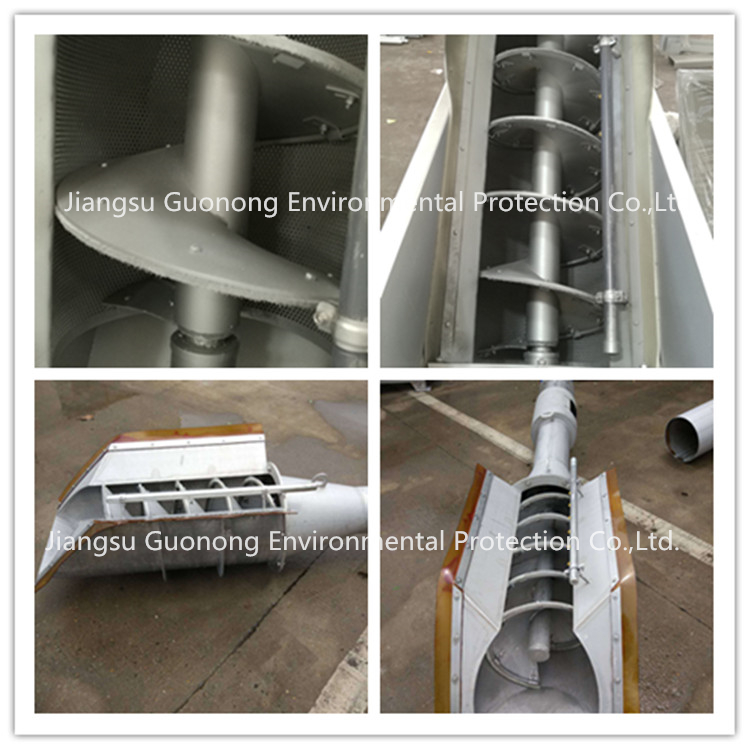

20-150m3/H 1.1KW U Troughs Economic Screw Sieve Screens

Screw Screen Features:

Screw Screen Technical Parameter

| Model | Flow Rate(m³/h) | Grid Gap(mm) | Power(kw) | Dimension(m) | Material |

| GNKGF-400 | 10-50 | 1-6mm | 0.75KW | 3.7*0.5*1.0m | SS304/316L |

| GNKGF-500 | 10-80 | 1-6mm | 0.75KW | 3.8*0.6*1.0m | SS304/316L |

| GNKGF-600 | 20-100 | 1-6mm | 0.75KW | 3.9*0.7*1.0m | SS304/316L |

| GNKGF-700 | 20-150 | 1-6mm | 1.1KW | 4.0*0.8*1.0m | SS304/316L |

Screw Screen Operating Principle

Particles that are collected on the filtering mesh of the screen are moved up along the barrel by a rotating spiral. At the same time, the mesh is thoroughly cleaned by peripheral brushes.

Waste compacting is achieved by the decreasing screw pitch. The organic contaminants are flushed from the waste by spray water from washing nozzles on the top of the barrel. Washing water and water pressed from the solid material is taken to the channel upstream of the screen by a pipeline. Washed and drained screenings are discharged into a waste bin at the discharge zone. The screen operation periodicity depends on the equipment automation scheme.

Screw Screen Features:

We offer a complete line of in channel or in-tank screening systems. Each unit utilizes a perforated plate or v-wire screen section to effectively remove unwanted solids and debris from the influent. The screenings are transported via a shaftless conveyor to the compactor and washing zone, where they are cleaned, dewatered, then finally discarded into a receptacle or optional bagging system. Screens can be installed in-channel or in a self-contained stainless steel tank.

Screw Screen Function

The process starts on the screen that holds back solids only. The internal part of the screen is continuously cleaned by brushes fixed on the outside diameter of the flighting. As the water runs through the screen the shaftless spiral conveys the solids up towards the compaction module where the material is further de-watered. Depending on the material properties, screenings can be reduced by more than 50% of their original volume.

Company Introduction:

Jiangsu Guonong Environmental Protection Co., Ltd is the professional water treatment R&D manufacturer. It is located in Yixing city, Jiangsu Province, China. Our products include Fine Bubble Disc Diffuser, MBBR Media , Sludge Dewatering Machine, Automatic Chemical Dosing System. Dissolved Air Flotation(DAF), Drum Filter Screen, Screens and Fine Screens, Grit-water separator, Screw Conveyor, Nano Bubble Generator, etc.

After years of exploration and practice, our company has developed into a comprehensive service system.

Now ,more than 80% of our products are exported to Southeast Asia, The Middle East, Europe, North America, Latin America , and so on. We also have many agents in Southeast Asia, North America and Latin America.

We insist on "Quality first, Reputation Foremost", our mission is" To be the best integrated water treatment supplier Worldwide".

FAQ

Q: Whether your company is factory or trading company?

A: Our company has its own workshop, so we can provide the the best

quality and the lowest price for you.

Q: How long is your warranty?

A: One year after the arrival of the goods. During this period, we

will provide the damaged parts for free if not man-made damage.

Q: What about your delivery time?

A: Normally within 30 days against down payment.

Q: What about the package of your export product?

A: We use anticorrosion wooden case with foam inside.

Q. Is there any other equipment used in sludge treatment?

Yes, including sludge dewatering machine, polymer dosing system, sludge thickener, conveyor device, rotary drum screen, coarse screen, dissolved air flotation(daf system), sludge scraper bridge, etc. If you are interested, contact us for further information.