Active Member

|

[China]

Address: No. 56, Chang'an Road, Baiyan Science and Technology Park, High-Tech Zone, Hefei City, Anhui Province, China, 230088

Contact name:Amy Zheng

Anhui Keye Intelligent Technology Co., Ltd |

|

Yakult Beverage Bottles Visual Inspection System For Surface Defects Detection

Inspection standards

| Model | Camera number | Detection range | Detection content | Accuracy | Precision | Speed |

| KVIS-C -SC11 | 1set | Bottle mouth | Black spots, stains, overlap, burrs, lack of material, etc. | ≥0.5mm | Qualified product 99.5% | 160 pcs/min |

| False detection is less than 0.5% | ||||||

| 1set | Bottom of the bottle | Black spots, stains,foreign material, etc. | ≥0.5mm | Qualified product 99.5% | ||

| False detection is less than 0.5% | ||||||

| 4 set | Upper area of the bottle | Black spots, stains,missing, etc. | ≥0.5mm | Qualified product 99.5% | ||

| False detection is less than 0.5% | ||||||

| 4set | Lower area of the bottle | Black spots, stains, etc. | ≥0.5mm | Qualified product 99.5% | ||

| False detection is less than 0.5% | ||||||

| 1set | Outer bottom of the bottle | Black spots, stains | ≥0.5mm | Qualified product 99.5% | ||

| Hole | ≥1mm | Qualified product 99.5% |

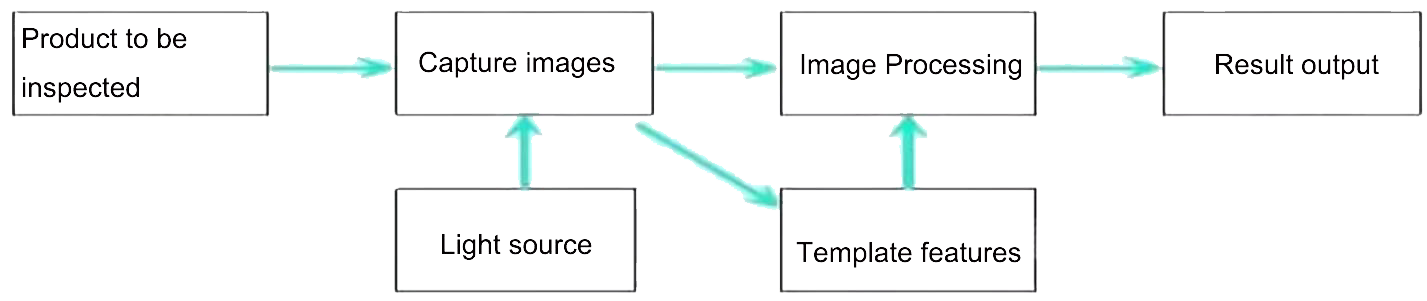

Detection principle

Yakult is a drink that is loved by children and young people, and its sales range has now covered more than 30 countries. Every country has stricter and stricter requirements for the packaging of this beverage before the innovation of this beverage and the huge market capacity. Therefore, many manufacturers also use high-tech packaging visual inspection equipment when using fully automatic production lines to increase production.

Through the testing equipment, unqualified products can be detected in the production process in time, and the possible problems in the production line can be checked, which can also save labor and improve production efficiency. It is an indispensable link in the production of enterprises. Keyi Technology has the latest artificial intelligence equipment. After continuous tempering, learning, and upgrading of tens of thousands of samples, it has been able to accurately detect various packaging problems, and the detection accuracy rate is as high as 99%.

Inspection principle

Transfer the bottle products to a specific station in a stable and orderly manner, and then transmit the captured high-pixel sample image to the image processing software through an industrial camera. Defective products are eliminated, and qualified products are finally collected.

The software will open the sample comparison standard, and the

production personnel at the customer site can control the

comparison accuracy and select the most suitable accuracy standard

for their own production conditions, thereby controlling the defect

rate. Greatly reduce costs.

Inspection details

Our design plan uses 11 sets of high-pixel industrial cameras and

high-performance stroboscopic light sources to carry out

comprehensive detection for bottle mouth, bottle bottom and bottle

body defects. The whole set of detection equipment includes

mechanical parts, visual electronic hardware and detection systems.

The software, the entrance and exit of the detection machine can be

integrated with the conveyor line, the detection speed is 9600

pieces/hour, the equipment can realize 7*24 hours of operation, and

the unqualified products can be automatically rejected.