Active Member

|

[China]

Address: No. 56, Chang'an Road, Baiyan Science and Technology Park, High-Tech Zone, Hefei City, Anhui Province, China, 230088

Contact name:Amy Zheng

Anhui Keye Intelligent Technology Co., Ltd |

|

Company Profile

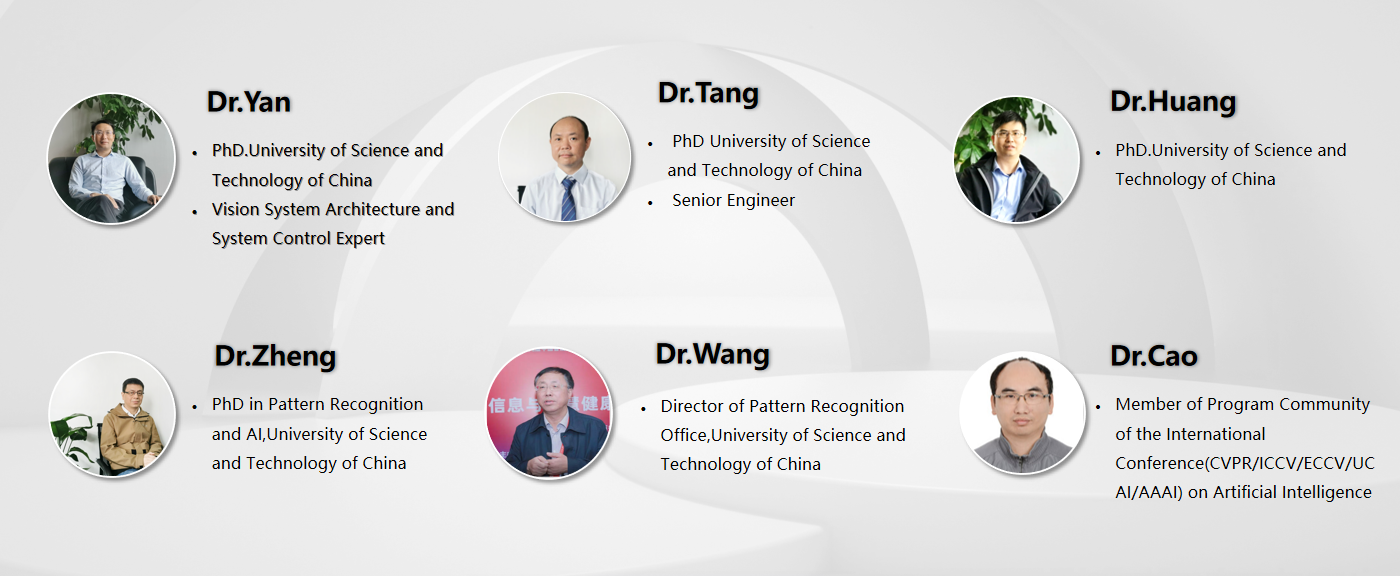

Keye Technology relies on the Keye Laboratory of Pattern Recognition of the University of Science and Technology of China, and has a high-level doctoral R&D team covering the entire technology chain of optics, mechanics, electricity, computing and software.

Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity. We provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Equipment Advantages

1. High accuracy, artificial intelligence AI detection, error control within 0.01%;

2. High efficiency, 2 minutes to complete the test, one is equivalent to 3 manual workers;

3. Intelligent, three-dimensional, easy to operate, you can use it in 3 minutes;

4. Femto-visible, high-precision camera omni-directional detection 0.04mm recognition accuracy.

Product Description

The equipment uses the latest AI vision detection technology and is equipped with 3 high-resolution cameras to analyze the attributes of the front and back sides of glutinous rice. Through the registration algorithm, the front and back sides of the glutinous rice are registered one by one, and their respective attributes are combined to obtain a synthesis. The properties of a whole piece of glutinous rice; use deep neural network to segment the sticky glutinous rice at instance level to easily deal with the sticking situation of glutinous rice; at the same time, open the cloud platform to remotely train samples of different customers to meet customer customized classification standards.

| Model.No | KVS-GW | Inspect speed | 900-1200pcs/min |

| Size | 800*600*600mm | Weight | 110kg |

| Voltage | 220V±10%,50Hz | Current | 500-1000W |

| Ambient temperature | 10~30℃ | Environment humidity | Relative temperature≤85% |

Key Technology

1. Automatic binarization: Use deep neural network to segment the foreground and background of the image. Compared with the traditional binarization method, it can be applied to a variety of lighting conditions, and the edge segmentation of wheat is smoother, fast and robust High advantages.

2. Adhesive wheat segmentation algorithm: The method based on connected domains cannot segment the adhered wheat. The deep neural network is used to segment the adhered wheat at an instance level, which can reach a speed of 1000fps and can process the adhered wheat in real time.

3. Wheat attribute recognition algorithm: It adopts lightweight neural network and integrates semi-supervised learning method. Iterative optimization of the model can be carried out with only a small amount of data marked by the user. It has the advantages of high accuracy, fast speed, and convenient deployment.

After-sale Service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.