Changzhou Victory Technology Co., LTD |

|

Verified Suppliers

|

|

Product Description

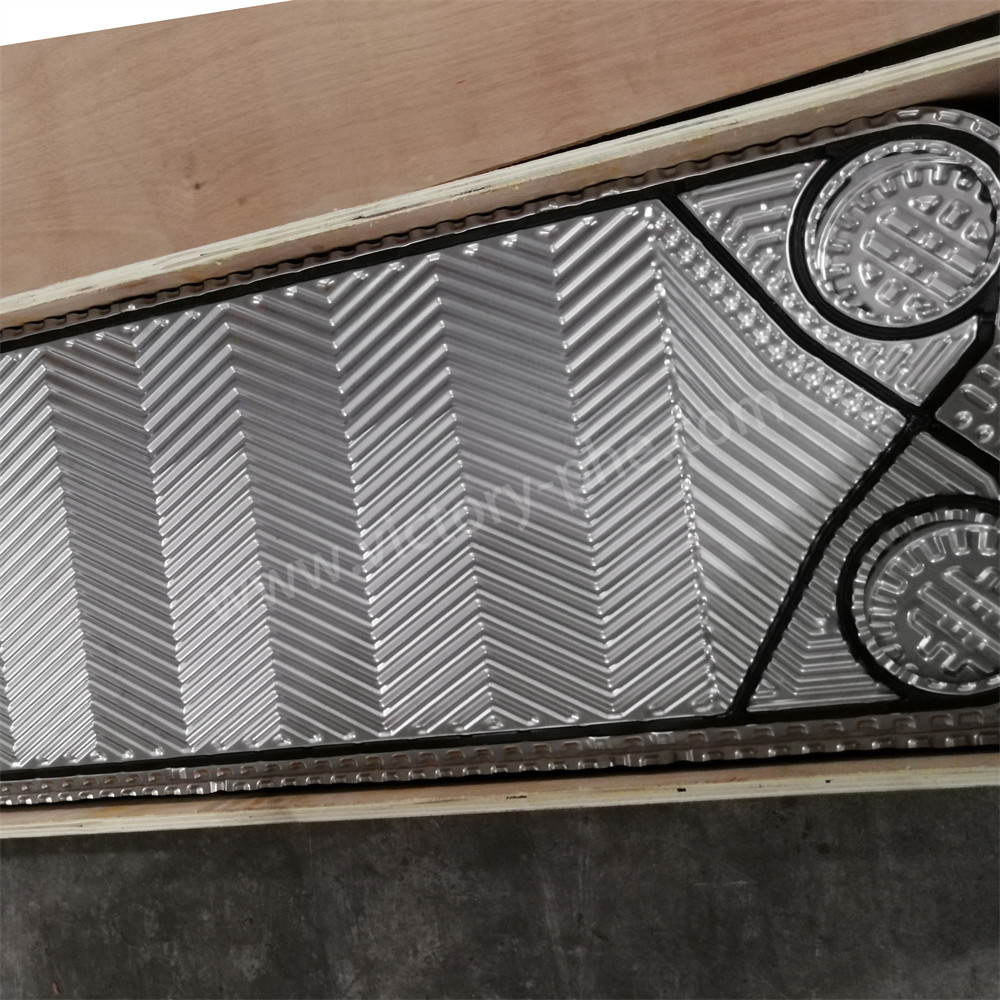

Optimized Design Heat Exchanger Plate V4,V8,VU8 for Sterilization in Pharmaceutical Production

Heat Exchanger Plates

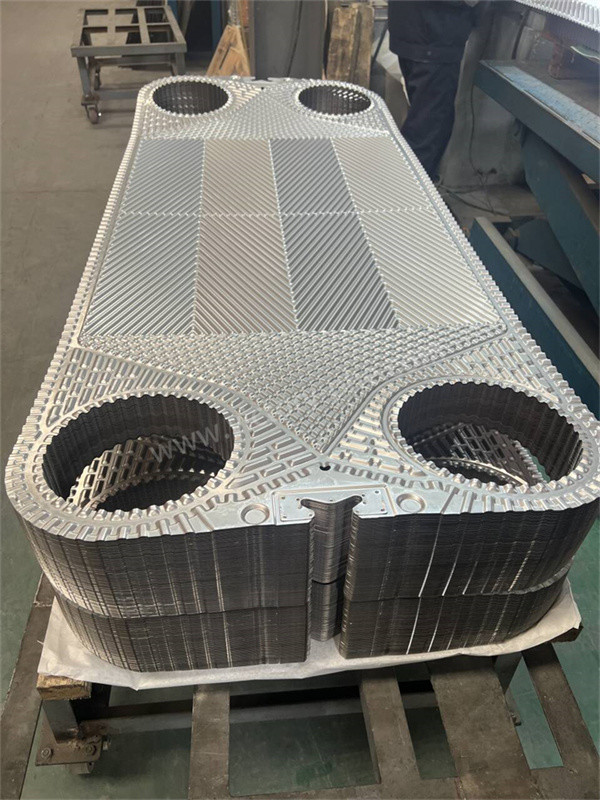

The Optimized Design Heat Exchanger Plates V4, V8, and VU8 are purpose-built to meet the exacting requirements of sterilization processes within pharmaceutical production. These specialized plates are engineered to ensure highly efficient heat transfer while adhering to the stringent hygienic standards crucial for pharmaceutical manufacturing.

Key Features:

Enhanced Heat Transfer Efficiency: The V4, V8, and VU8 heat exchanger plates are designed to maximize heat transfer, enabling rapid and precise temperature control required for sterilization processes in pharmaceutical production.

Corrosion-Resistant Materials: These plates are constructed from materials that are highly resistant to corrosion, ensuring durability and longevity, even in the challenging chemical environments typically encountered during pharmaceutical sterilization processes.

Sanitary Design Specifications: Equipped with sanitary connections and surfaces, these plates adhere to strict hygiene standards, significantly reducing the risk of contamination and maintaining the integrity of pharmaceutical products during the sterilization process.

Versatile Configurations: The V4, V8, and VU8 plates offer a range of customizable configurations to accommodate diverse heat exchange requirements, providing adaptability for various sterilization applications in pharmaceutical manufacturing.

Compliance and Certifications: These heat exchanger plates are designed to meet industry standards and certifications, ensuring compliance with regulatory requirements and guaranteeing product quality and safety in pharmaceutical manufacturing processes.

| Brand | Model |

| V4,V8,VU8,V13,V20,V28,V45,V60 |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

Products are mainly suitable for ACCESSEN/GEA (Kelvion)/ APV/ Sondex/ Tranter/ Hisaka/ API/ Funke/ Vicarb/ Mueller/ SWEP/ Fischer/ AGC/ Thermalwave/ ITT/ LHE/ DHP, etc.

Applacations

| Plate material | Suitable for fluids |

| Stainless steel (SUS304.316, etc.) | Purified water, river water, edible oil, mineral oil |

| Titanium and titanium palladium (Ti, Ti-Pd) | Sea water, salt water, salt compounds |

| 20Cr,18Ni,6Mo(254SMO) | Dilute sulfuric acid, dilute salt aqueous solution, inorganic aqueous solution |

| Nickel (Ni) | High temperature, high concentration caustic soda |

| HASTELLOY alloy (C276, D205, B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |

Plate heat exchanger plate thickness configuration

Production Process: