Changzhou Victory Technology Co., LTD |

|

Verified Suppliers

|

|

Product Description

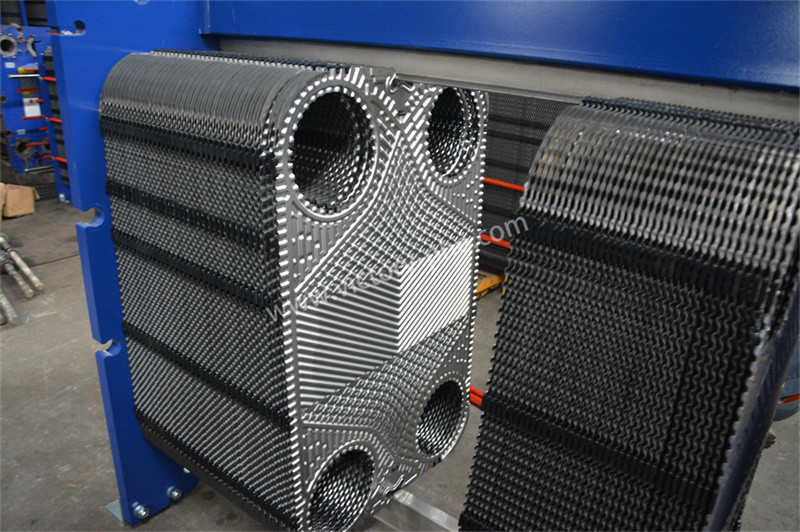

Water Oil heat Exchange Sondex Heat Exchanger Plates S100 S121 S4A Types

Sondex Heat Exchanger Plates

Sondex heat exchanger plates work based on the principles of heat transfer through the interaction of two separate fluid streams. The design of Sondex heat exchanger plates allows for efficient heat exchange between the fluids while keeping them physically separated. Here's an overview of how Sondex heat exchanger plates work:

Sondex Plate Heat Exchanger: Efficient Heat Transfer through Innovative Design

Sondex plate heat exchangers leverage a carefully engineered flow configuration to facilitate effective heat transfer between two fluid streams. The plates feature distinct channels, with one fluid flowing on each side in a counterflow arrangement. This counterflow principle maximizes the temperature difference between the fluids, enabling efficient heat exchange.

The plate design also induces turbulent flow in the fluid streams, which enhances heat transfer by preventing boundary layer formation and promoting thorough mixing. Together with the large surface area of the thin metal plates, this turbulent flow ensures optimal thermal efficiency, minimizing pressure drop and maximizing the overall heat transfer coefficient.

Underpinning the performance of Sondex plate heat exchangers is a commitment to innovative design and engineering. The plates are meticulously crafted to deliver reliable, high-efficiency heat transfer, making Sondex solutions suitable for a diverse range of industrial, commercial, and residential applications. Whether for heating, cooling, or process requirements, Sondex plate heat exchangers provide a robust and flexible means of managing thermal energy transfer.

| Brand | Model |

Sondex | S1,S4,S4A,S7A,S8,S8A,S9A,S14,S14A,S17,S19A,S20A,S21A S22A,S31A,S22,SW26,S37,SW40A,S41,S41A,S42,S42A,S62,S43 S47,SN51,S52,S64,S65,S81,S100,S121,SF123,SF160 |

| Material | Specification |

| Stainless Steel | SUS304 316 316L 310S 904 |

| Titanium and titanium-palladium alloy | TAi TAi-Pd |

| Hastelloy | C276 D205 B2G |

| Nickel | Ni200 Ni201 |

| Molybdenum | 254 |

Heat Exchanger Plate Material Choose:

Applacations

| Plate material | Suitable for fluids |

| Stainless steel (SUS304.316, etc.) | Purified water, river water, edible oil, mineral oil |

| Titanium and titanium palladium (Ti, Ti-Pd) | Sea water, salt water, salt compounds |

| 20Cr,18Ni,6Mo(254SMO) | Dilute sulfuric acid, dilute salt aqueous solution, inorganic aqueous solution |

| Nickel (Ni) | High temperature, high concentration caustic soda |

| HASTELLOY alloy (C276, D205, B2G) | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid |