Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

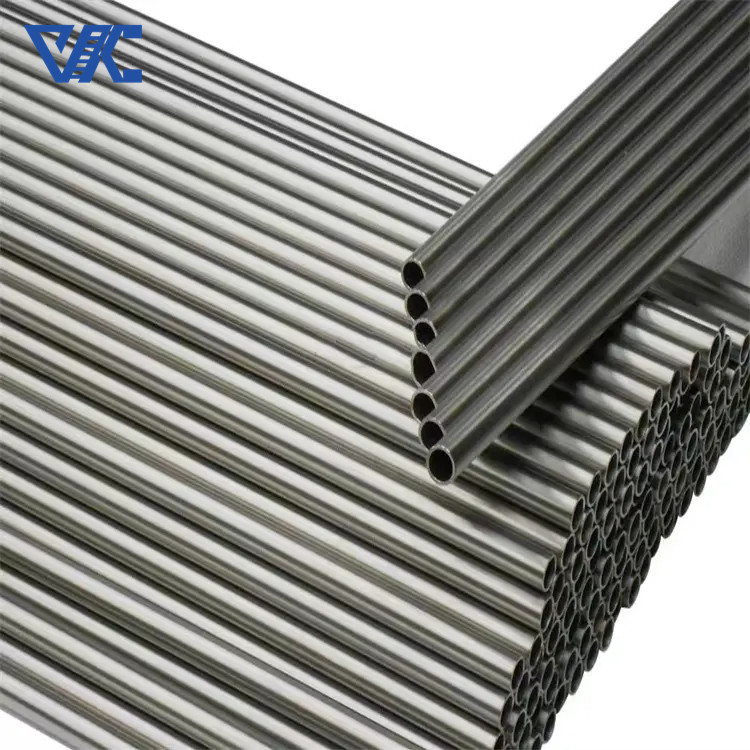

ASTM B167 / ASME SB 167 UNS N06601 Nickel Alloy Inconel 601 Seamless Steel Pipe & Tube Manufacturer

Nickel-based characteristics Inconel is a nickel-based superalloy whose main component is nickel. Nickel-based alloys have excellent high-temperature strength, corrosion resistance and oxidation resistance. These characteristics make Inconel alloys perform well in high-temperature, corrosive environments.

With the development of series products, Inconel alloy has gradually formed a product series, including Inconel 600, Inconel 601, Inconel 625, Inconel 718, Inconel X750 and other different grades of alloys. These Inconel series products meet the needs of different application areas.

What Are The Features Of Inconel Alloy 601?

Inconel 601 has excellent high temperature resistance and its oxidation resistance remains excellent at high temperatures of 1250°C (2282°F). This is attributed to the dense and continuous oxide film formed on the surface of Inconel 601. This passive oxidation layer can protect the substrate well, allowing Inconel 601 to maintain excellent antioxidant properties and avoid peeling when undergoing repeated heating and cooling cycles.

Inconel 601 pipe meets ASTM B167 standards and is a seamless pipe. The special passivation oxide layer formed on the surface of this pipe further enhances its resistance to corrosion and oxidation. This enables Inconel 601 pipe to perform excellently in high temperature and corrosive environments.

In general, Inconel 601 not only exhibits excellent oxidation resistance at extremely high temperatures up to 1250°C, but the dense oxide film formed on its surface can also effectively inhibit spalling and ensure long-term stable operation of the pipe in harsh environments. This makes it a preferred material in aerospace, power generation equipment and other fields.

What Are The Applications Of Inconel Alloy 601?

Aerospace field:

Turbine engine parts such as blades, fuel nozzles, etc.

Missile and Rocket Parts

Hypersonic vehicle structure

Power generation equipment field:

Gas turbine and steam turbine parts

Boiler piping and heat exchange equipment

Petrochemical field:

Reactors, heat exchangers, pipelines, etc. of petrochemical

equipment

Offshore oil platform equipment

Metallurgical industry:

Pipelines and parts in high-temperature equipment such as electric furnaces and coking ovens.

chimney lining

Process equipment field:

Pipes and parts for various high-temperature, high-pressure, and

corrosive process equipment

Molten metal conveyor pipe

Military equipment field:

High-performance components for combat vehicles and weapon systems

Automobile industry:

High performance exhaust system lines and parts

Inconel Alloy Series Composition:

| Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel718 | Inconel X750 | Inconel 825 |

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

| Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | -- | -- | ≤0.6 | ≤1.15 | -- | ≤1.15 | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

| Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

| B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Inconel 601 Alloy Parameter:

| Inconel 601 | Tensile strength (Rm N/mm2) | Yield strength (RP0.2N/mm2) | Elongation A5 (%) | Brinell hardness (HB) | Density(g/cm3) | Melting Point (℃) |

| Annealing | 650 | 300 | 30 | --- | 8.1 | 1320-1370 °C |

| Solution treatment | 600 | 240 | 30 | ≤220 |