Active Member

|

[China]

Contact name:Wang

Xinxiang Tongxin Machinery Co., Ltd. |

|

Calcium Carbonate Rotary Vibrating Screen Artificial Graphite Phosphate Soybean

Introduction

Three-D rotary vibrating sieve is one of precise

powder sieving machine, it has low noise and high efficiency, need

only 3-5 minutes to rapidly replace the screen, all closed

structure. It can be used to sieving,grading and sizing particles,

powder and mucilage.

Working Principle

The vibration is accomplished by eccentric weights on the upper and lower ends of the motion-generator shaft.

The direction of the eccentric weights can change its rotational mode,rotation of the upper weight creates vibration in the horizontal plane, which causes material to move across the screen cloth to the periphery,while the lower weight acts to tilt the machine, causing vibration in the vertical and tangential planes.

The trajectories of materials on the screen can be changed by adjusting the phase angle of upper and lower weights

Function

1. Sizing: segregate dry power or particles into various sizes.

2. Removing: get rid of a small quantity of impurity.

3. Filtering: solid-liquid separating.

Advantages and Features

1. Small in size and light in weight;

2. High screening accuracy and efficiency;

3. The screen is non-blocking and can screen 28 micron materials;

4. The screen cloth is easy to change and clean;

5. Completely sealed.

Apply in Industry

1. Dry separation-Separation of different materials on the basis of

their particle shape.

2. Dry classification-Separation of solid particles into precise

sized fractions.

3. Solid / Liquid separation dewatering of solids and clarification

of liquids.

4. Food processing ,chemical, medical powder and particle, coating,

pigment, cosmetic, grease, resin, ceramic sauce, slurry.

5. Chemical industry: resin, coating, drugs, cosmetic, painting,

powder etc.

6. Waste Recycle: waste oil, waste water, auxiliaries, activated

carbon etc.

Technical Parameters

| Stuff | Proportion | Mesh | Model | Methods | Capacity |

| In Powder | 0.8 | 80,180 | SZX-800-2S | Dry | 150 kg |

| Injection | 1.0 | 0.028mm | SZX-800-1S | Liquid | 800 |

| Pharmaceuticals | 0.7 | 20,80 | SZX-800-2S | Dry | 800 kg |

Our Advantage

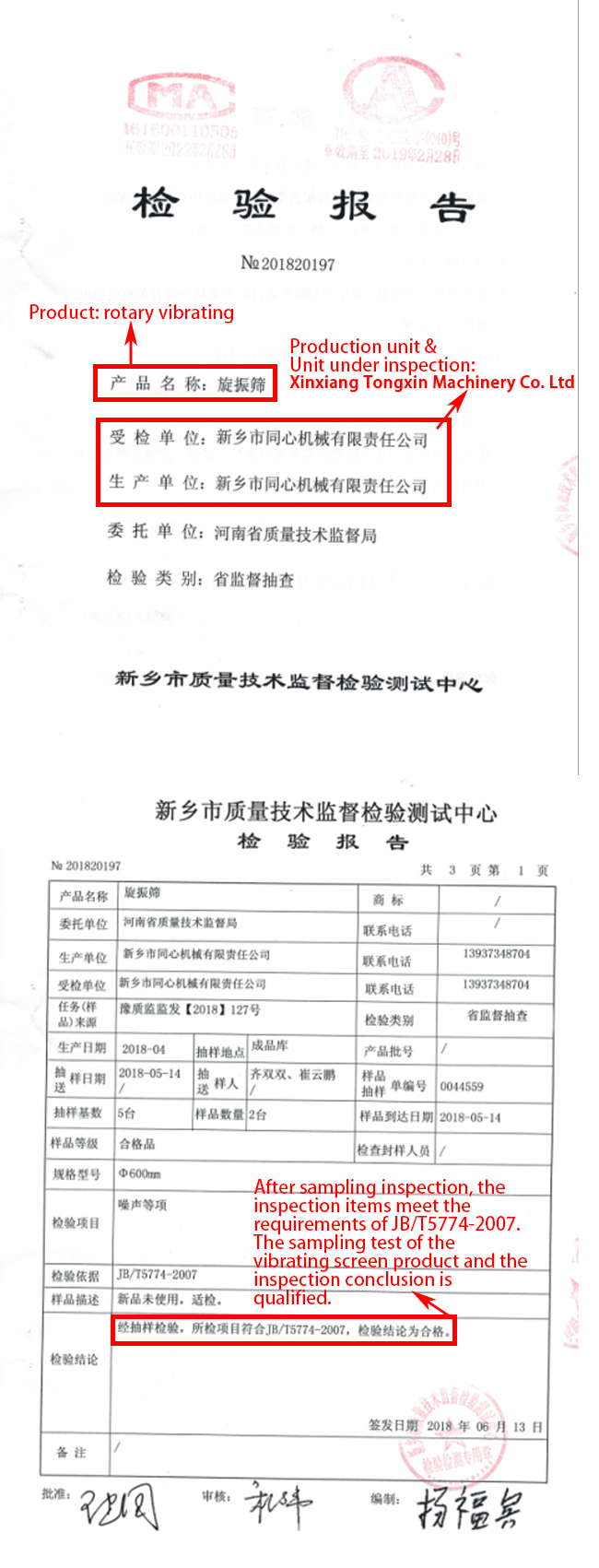

The product of Tongxin company can be sent to the Quality and Technical Supervision Bureau for mesh detection, if not in line with the national standards for you free return and replacement. the follow picture is our quality inspection report.

Our Service

1. We provide 12 months quality warranty;

2. We have professional engineer team ensure to provide the most professional equipment;

3. Professional engineers team can choose the right equipment for you;

4. We can provide thorough after-sales service to ensure the proper use of machine.

5. We can provide OEM customization.

If you want to get more information of product, please contact us!