Suzhou Best Bowl Feeder Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

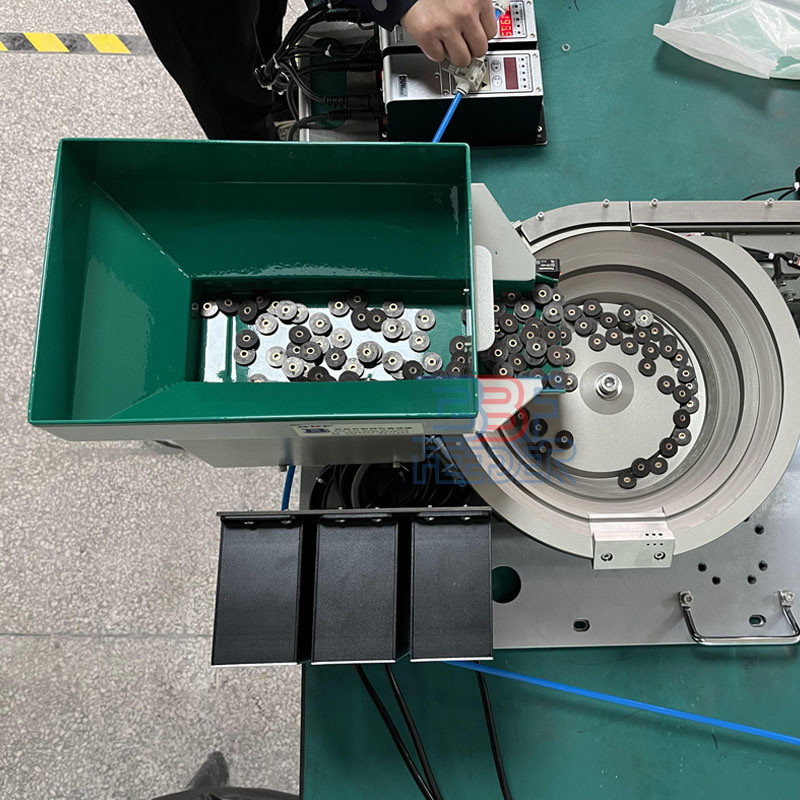

Assembling Vibration Bowl Feeder Hardware Fittings Automatic Part Feeder Vibratory

1 . Descriptions:

Bowl feeders are vital systems used in manufacturing to sort and align parts through vibration. They utilize a vibrating drive unit and variable-amplitude controller to create movement, ensuring the parts inside the bowl shift and align uniformly. This prepares them for assembly or packaging.

Our company offers a diverse range of bowl feeders tailored to handle different parts, elements, and products with precision and efficiency. By customizing an automated solution for your production line, you can boost productivity and meet fulfillment targets.

The versatility of bowl feeders extends across various industries, including electronics and beauty products, where they play a crucial role in ensuring smooth and accurate manufacturing operations.

In the electronics sector, bowl feeders excel in sorting and aligning electronic components, whether for printed circuit boards or mobile phone assembly. The systematic arrangement facilitated by bowl feeders significantly speeds up the manufacturing process.

For battery manufacturing, bowl feeders are essential to achieve precise orientation of battery cells and connectors during assembly. This improves production efficiency and enhances the overall quality and reliability of the batteries.

In the cosmetics and personal care industry, bowl feeders are invaluable for positioning items like lipstick tubes and mascara wands with exceptional accuracy. This meticulous arrangement streamlines processes such as labeling, branding, and sealing, resulting in a seamless production line.

Industries that prioritize safety and precision, such as medical equipment manufacturing, rely on bowl feeders to organize syringe elements and assemble intricate medical tools. Bowl feeders ensure correct alignment, contributing to impeccable assembly and packaging.

To summarize, bowl feeders are indispensable tools in manufacturing. They enable efficient part sorting and alignment, offering versatility, precision, and productivity enhancements across various industries.

2 . Specifications:

| Product name | Vibratory Bowl Feeder |

| Material | Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller | CUH,Sanki,Sinfonia,REO,Afag |

| Voltage | 220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power | 300W/500W/1000W/1500W/2000W |

Package | Wooden Case Package |

| Speed | Based on Customers Requirements |

| Warranty | 2 Years |

| Certification | CE, ISO9001, ROHS |

| Lead Time | 3 Working Weeks |

3 . How Vibratory Bowl Feeders Reduce Waste :

Automation has revolutionized manufacturing, enhancing efficiency, reducing waste, and promoting sustainability. This article focuses on how automation addresses waste management, with a specific emphasis on cost reduction and environmental impact.

Automated production lines minimize human error, reduce downtime, and optimize processes using robotics, machine learning, and AI. This leads to increased production rates and reduced waste generation. Precision and quality control are ensured through real-time monitoring of products, resulting in early defect detection and improved customer satisfaction.

Automation enables efficient inventory management and just-in-time manufacturing, reducing waste from excess inventory and unsold products. Resource optimization is achieved through advanced technologies that control material inputs and monitor energy usage. This leads to minimized waste generation and lower costs.

In terms of sustainability, automation plays a vital role by optimizing production processes, reducing the carbon footprint, and integrating renewable energy sources. This minimizes reliance on fossil fuels and mitigates greenhouse gas emissions.

In conclusion, automation in manufacturing brings significant benefits in waste reduction, cost reduction, and environmental sustainability. It improves efficiency, quality control, resource utilization, and inventory management, leading to minimized waste and enhanced profitability. Embracing automation technologies paves the way for a future with reduced waste, lower costs, and a smaller environmental impact.

4 . More Pictures: