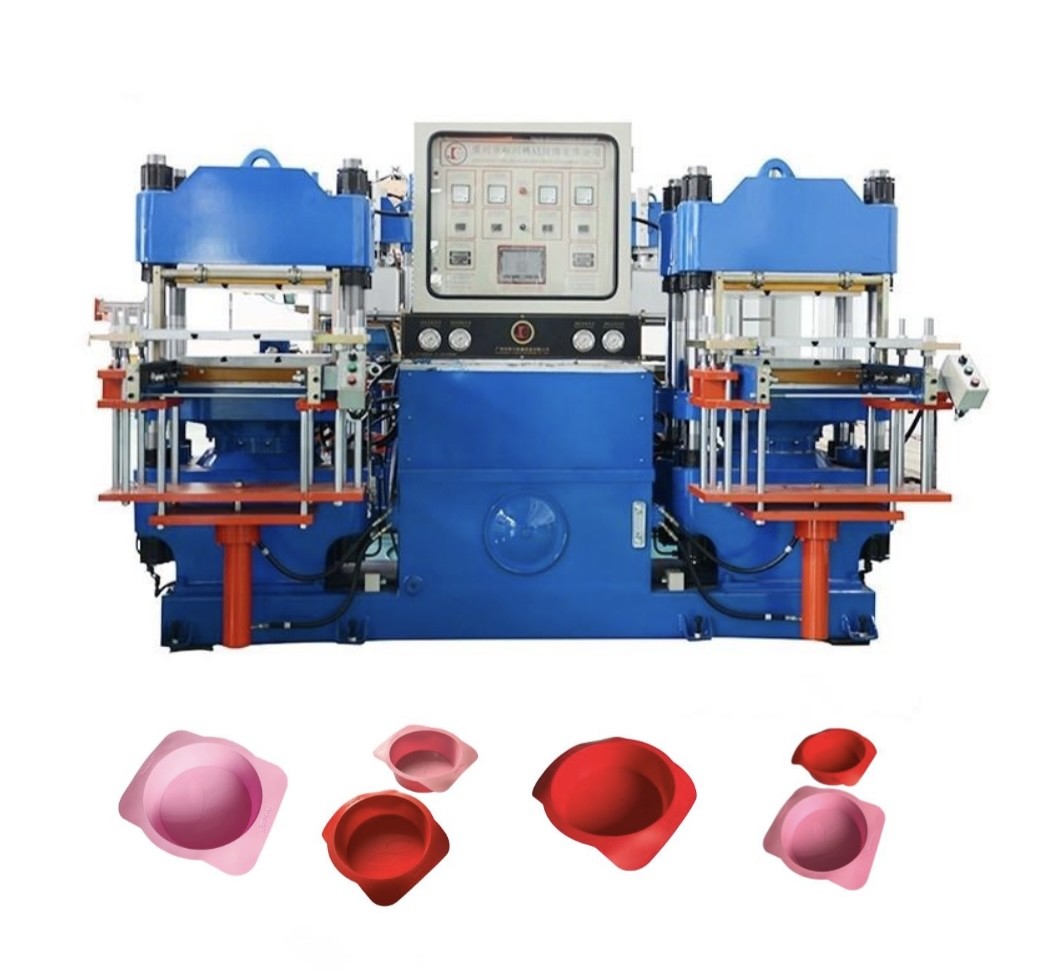

Guangzhou Juchuan Machinery Co., Ltd. |

|

Verified Suppliers

|

|

| Clamp Force: | 200 Ton | Plate Size: | 550x560mm |

|---|---|---|---|

| Plunger Stroke: | 250mm | Heating Plate Distance: | 250-350mm |

| Tie Bar Distance: | 650x320mm | Dimension: | 2930*2350 *2050 |

| High Light: | hydraulic vulcanizing machine,rubber vulcanization molding machine | ||

Main Features:

Machine motions flow:

200 Ton paremeter:

| Model | Unit | 200HF |

| Clamping Force | Ton | 200 |

| Operation table size | mm | 550*560 |

| Plunger stroke | mm | 250 |

| Distance of | mm | 250~350 |

| Thermo-plate | ||

| Distance of Tie bar | mm | 640*310 |

| Die sinking type | Track-Suspension-2RT-3RT-4RT | |

| Max Operating | Mpa | 20 |

| Pressure | ||

| Motor Power | hp | 10*2(7.5kw*2) |

| Electric Heating | Kw | 13.5*2 |

| Power | ||

| Total Power | Kw | 42 |

| Gross weight | Ton | 7.8 |

| Dimension(L*W*H) | mm | 2930*2350*2050 |

Main Technical Parameters:

| Model | Unit | 250HF | 300HF | 400HF | 500HF | 1200HF |

| Clamping Force | Ton | 250 | 300 | 400 | 500 | 1200 |

| Operation table size | mm | 650*600 | 700*800 | 850*850 | 1000*1000 | 1600*2200 |

| Plunger stroke | mm | 250 | 300 | 300 | 350 | 350 |

| Distance of Thermo-plate | mm | 250~350 | 300~400 | 300~400 | 350~450 | 350~550 |

| Distance of Tie bar | mm | 745*310 | 785*380 | 940*450 | 1105*475 | 6 posts |

| Die sinking type | Track-Suspension-2RT-3RT-4RT | |||||

| Max Operating Pressure | Mpa | 20 | 20 | 20 | 20 | 20 |

| Motor Power | hp | 10*2(7.5kw*2) | 10*2(7.5kw*2) | 15*2(11kw*2) | 15(11kw) | 25(18.5kw) |

| Electric Heating Power | Kw | 15.3*2 | 24*2 | 26.4*2 | 36 | 126 |

| Total Power | Kw | 45.6 | 63 | 74.8 | 47 | 144.5 |

| Gross weight | Ton | 11 | 15 | 17 | 13.5 | 28.5 |

| Dimension(L*W*H) | mm | 3190*2780 *2230 | 3360*2970 *2250 | 3660*3050 *2350 | 1460*3600 *2380 | 2350*5400 *2950 |

Our Services:

1. Free technology training: you can come for inspection and training for free.

2. Free Installation and debugging: Our engineers will teach you about the installation and debugging for free.

3. After-sales service: We will not only supply the free repairmen on this machine for one year, but will supply the maintenance lifetime. (The service is only for natural damage)

4. Online remote control for software problems, whatspp or wechat for video checking.