Hangzhou Powersonic Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Ultrasonic homogenizer emulsifier in different industrial usage with high amplitude sonotrode

What is ultrasonic emulsifier?

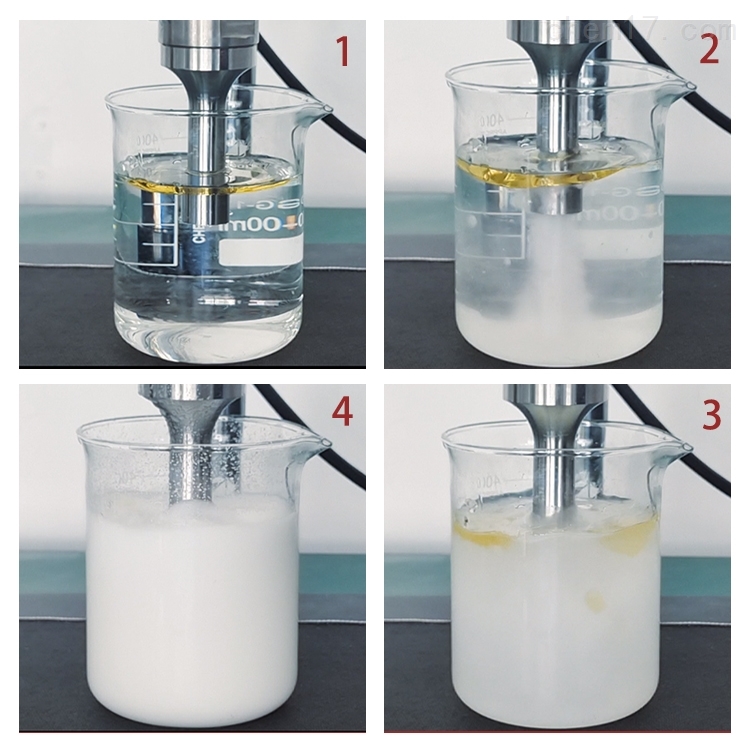

Ultrasonic emulsification refers to the process of mixing two (or

more than two) immiscible liquids evenly to form a dispersion

system under the action of ultrasonic energy, in which one liquid

is evenly distributed in another liquid to form an emulsion.

principle:

The physical mechanism for crushing insoluble solids (or liquids)

is believed to be ultrasonic cavitation. Ultrasonic cavitation

effect means that under the action of strong ultrasonic waves, a

large number of bubbles will be generated in the liquid. The small

bubbles will gradually grow and increase with the ultrasonic

vibration, and then suddenly burst and split. The split bubbles

will continue to grow and burst. . When these small bubbles

collapse rapidly, high temperature and high pressure are generated

in the bubble, and because the liquid around the bubble rushes into

the bubble at high speed, a strong local shock wave is generated in

the liquid near the bubble, which also forms local high temperature

and high pressure, thus producing Ultrasonic crushing and

emulsification.

What is the application of a emulsifer in Industrial use?

In the pharmaceutical industry and daily necessities industry

sector, phacoemulsification is often used to manufacture various

emulsion products, such as emulsion drugs, cosmetics, and leather

shoe polish. Ultrasonic emulsification method can also be used to

produce emulsified combustion products of oil (gasoline, diesel,

etc.) and water or pulverized coal to improve the combustion value

of unit fuel.

This technology has now been promoted and used within a limited

scope, and the economic benefits are obvious. In order to reduce

costs and adapt to larger-scale production, mechanical ultrasonic

transducers such as reed whistles are mostly used in

phacoemulsification. For liquids that are difficult to emulsify or

for other special considerations, piezoelectric ultrasonic

transducers are sometimes used together with an appropriate sound

focusing system to increase the sound intensity.

Phacoemulsification has been used in many fields and plays its

unique role in each field.

There are many industrialized applications of phacoemulsification,

and phacoemulsification is one of the earliest technologies for

ultrasound to be used in food processing. For example, soft drinks,

ketchup, mayonnaise, jam, artificial milk, baby food, chocolate,

salad oil, oily sugar water and other mixed foods used in the food

industry have been tested and adopted at home and abroad, and have

achieved improvements. The effect of product quality and production

efficiency, and aqueous carotene emulsification has been

successfully tested and used in production.

The banana peel powder was pre-treated using physical modification

method of ultrasonic dispersion combined with high-pressure

cooking, and then enzymatically hydrolyzed by amylase. A single

factor experiment was used to study the effect of this pretreatment

method on the extraction rate of soluble dietary fiber in banana

peels and the physical and chemical properties of insoluble dietary

fiber in banana peels. The results showed that ultrasonic

dispersion combined with high-pressure cooking is better than

simple treatment without pretreatment. The insoluble dietary fiber

obtained by enzyme treatment has an increase in water holding

capacity of 5.05g/g, water binding capacity of 4.66g/g, oil holding

capacity of 4.60g/g, and swelling property of 0.4mL/g.

Parameter:

| Item | sono-20-1000 | sono-20-2000 | sono-20-3000 | sono-15-3000 |

| Frequency | 20khz±0.5 | 20khz±0.5 | 20khz±0.5 | 15khz±0.5 |

| Power | 1000w | 2000w | 3000w | 3000w |

| Voltage | 110 or 220V | |||

| Max temp | 300℃ | |||

| Max pressure | 35Mpa | |||

| Itensity of sound | 20W/cm² | 40W/cm² | 60W/cm² | 60W/cm² |

| Capacity | 10L/min | 15L/min | 20L/min | 20L/min |

| Material of probe | Titanium | |||

what is the best emulsifier?

The average droplet size of the emulsion formed by ultrasonic

emulsification is small, which can be 0.2 to 2um; the droplet size

distribution range is narrow, which can be 01 to 10um or

narrower.

The concentration of ultrasonic emulsion is high. The concentration

of pure emulsion can exceed 30%, and the concentration of

emulsifier can be as high as 70%.

The formed emulsion is more stable. An important feature of

ultrasonic emulsification is that no or less emulsifiers can be

used to produce an extremely stable emulsion.

You can control the type of lotion. Using ultrasonic

emulsification, under certain sound field conditions, both O/W

(oil-in-water) and W/O (water-in-oil) emulsions can be prepared;

however, this is not possible with mechanical emulsification

methods, only the properties of the emulsifier You can control the

type of lotion.

Toluene emulsifies in water, forming one type of emulsion under low

sound intensity conditions and another type of emulsion under high

sound intensity conditions.

Ultrasonic emulsification requires little power to produce milk

residue.

how is the ultrasonic make efficient emulsification?

Ultrasonic emulsification achieves efficient emulsification through a phenomenon called cavitation. Cavitation refers to the formation, growth, and violent collapse of microscopic bubbles within a liquid.

When an ultrasonic emulsifier is operated, it emits high-frequency sound waves into the liquid medium. These sound waves create alternating high-pressure and low-pressure cycles in the liquid, leading to the formation of tiny bubbles through a process called nucleation. These bubbles are typically on the order of micrometers in size.

During the low-pressure cycle of the sound wave, the bubbles expand due to reduced pressure. As the pressure increases during the high-pressure cycle, the bubbles rapidly collapse. This collapse of the bubbles is known as implosion or cavitation.

The collapse of these bubbles generates localized hotspots with extremely high temperatures and pressures. The temperature inside the collapsing bubbles can reach thousands of degrees Celsius, while the pressure can exceed 1,000 atmospheres. This phenomenon is called transient cavitation.

The violent collapse of the bubbles during cavitation produces intense shear forces, shockwaves, and microjets within the liquid. These forces cause the disruption and breakup of larger droplets or particles into smaller ones. The liquid experiences intense turbulence, resulting in the dispersion of the dispersed phase into smaller droplets and their distribution throughout the continuous phase.