Mitech CO.,LTD. |

|

Mitech MHBRVU-187.5 II Advanced Optical Hardness Tester

Mitech MHBRVU-187.5II advanced optical hardness tester, based on the mechanical principle of diamond or spherical cemented carbide indenter pressing into the sample surface to produce indentation, realizing Brinell, Rockwell, Vickers three different materials hardness measurement by measuring the depth or diameter of the indentation. With novel appearance, full-featured, Rockwell hardness value can be directly read by the optical projection screen, Vickers, Brinell hardness values need to look up the table, easy operation, it can meet the needs of users of a variety of hardness testing. It is widely used in metal processing and manufacturing, various metal material’s failure analysis and other fields like colleges and research institutions. It is the new type multifunctional testing instrument for mental and part of the the non-metallic materials research and hardness test.

| Technical specifications | Technical Parameters |

| Preliminary testing force | 98.07N(10kgf) |

| Brinell testing force | 306N(31.25kg),613N(62.5kg),1839N(187.5kg)Tolerance±1.0% |

| Rockwell testing force | 588N(60kg),980N(100kg),1471N(150kg)Tolerance±1.0% |

| Vickers testing force | 294N(30kg), 980N(100kg)Tolerance±1.0% |

| Brinell measuring range | 8HBW~650HBW |

| Rockwell measuring range | 20HR~100HR |

| Vickers measuring range | 14HV~1000HV |

| Brinell scale | HBW2.5/31.25, HBW2.5/62.5, HBW2.5/187.5, HBW5/62.5 |

| Rockwell scale | HRA , HRB, HRC, HRD, HRE, HRF, HRG, HRK, HRH |

| Vickers scale | HV30, HV100 |

| Diamond indenter specifications | Diamond Rockwell indenter, diamond Vickers indenter |

| Steel ball indenter specifications | φ1.5875mm, φ2.5mm, φ5mm steel ball indenter |

| Drum minimum scale value | 0.002mm |

| Testing Force Application Mode | Semi-automatic (loading, holding, unloading) |

| Indenter objective lens conversion mode | Manual operation |

| Microocular magnification | 2.5X(Observing), 5X(measuring) |

| Eyepiece magnification | 15x |

| Test force holding time | 2~60s |

| Display features | High - end optical projection screen |

| Max sample height | 220mm(Brinell, Vickers),260mm(Rockwell) |

| Maximum distance of indenter to fuselage center | 200mm |

| Voltage | AC220V, 50Hz |

| Dimensions | 600*300*900mm |

| Total Weight | 130kg |

Working Principle

Brinell hardness test: Test force(F) is on the steel ball with certain diameter(D) , pressed on sample surface. After a period of time, cancel the force. The indentation diameter is get by measuring with micrometer ocular,thus to calculate the average pressure(N/mm²).Then we can get the Brinell hardness.

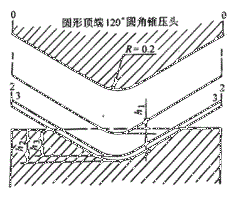

Rockwell hardness test is a vertex angle of 120 ° diamond cone or a certain diameter of the hardened steel ball as a pressure to the specified test force will be pressed into the sample surface, according to the sample surface indentation depth to be measured The Rockwell hardness of metallic materials.

Micro-Vickers (or Knoop) hardness test principle is that put the provisions of the positive pyramid diamond indenter into the sample surface(with fixed experimental force) and maintain a certain length (holding), and then unloading. Finally, there is a positive quadrangular pyramid or kenup indentation with a square surface on the surface of the specimen. Then we can attain the area of indentation via measuring the length of the diagonal by a micrometer eyepiece. Then the corresponding Vickers (or Knoop) hardness values are obtained.

Brinell working principle Figure

Rockwell working principle figure Vickers working principle figure

Feautures

Scope of application

Applications

Configurations

| NO. | Name | QTY. | Remarks | |

Standard Configuration | 1 | Main unit | 1 | |

| 2 | Rockwell diamond indenter | 1 | ||

| 3 | Vickers diamond indenter | 1 | ||

| 4 | Carbide ball indenter φ1.5875mm, φ2.5mm, φ5mm | 3 | ||

| 5 | Large Testing Table | 1 | For Rockwell hardness test | |

| 6 | Medium Testing Table | 1 | For Rockwell hardness test | |

| 7 | V-shape Testing Table | 1 | For Rockwell hardness test | |

| 8 | Standard Rockwell hardness blocks | 3 | ||

| 9 | Standard Brinell hardness blocks | 1 | ||

| 10 | Standard Vickers hardness blocks | 1 | ||

| 11 | Counterweight | 5 | Numbers 0 to 4 | |

| 12 | Objective lens | 2 | 2.5X, 5X | |

| 13 | Measuring microscopic | 1 | 15X | |

| 14 | Microscope seat | 1 | ||

| 15 | Slipped Table | 1 | ||

| 16 | Cone-shape Table | 1 | ||

| 17 | Spare bulbs | 2 | ||

| 18 | Fuse(0.5A) | 2 | ||

| 19 | Lighting head | 1 | ||

| 20 | Lighting shade | 1 | ||

| 21 | Power cable | 1 | ||

| 22 | Plastic dust cover | 1 | ||

| 23 | Attached files | 1 | ||

| 24 | Host accessories box | 1 |

Maintenance and care