MITECH MHB-3000 Electronic Brinell Hardness Tester

Overview

Mitech MHB-3000 Electronic Brinell Hardness Tester, based on the

mechanical principle of hard alloy indenter pressing into the

sample surface to produce indentation, realizing the material

hardness measurement by measuring the diameter of the indentation ,

it is novel and high reliable with accurately measurement. LED

eight digital tubes and luminescent secondary tube display, simple

operation, it can visually display the test results to meet the

hardness testing requirement for the quality control and qualified

assessment of the workpiece sample. It is widely used in metal

processing and manufacturing, various metal material’s failure

analysis and other fields like colleges and research institutions.

It is the new type Brinell hardness testing instrument for testing

the hardness of the materials like cast iron, steel, soft alloy and

so on.

Technical Parameters

| Technical specifications | Technical Parameters |

| The power series | 612.5N(62.5kgf),980N(100kgf),1225N(125kgf),1837.5N(187.5kgf),

2450N(250kgf),4900N(500kgf),7350N(750kgf),9800N(1000kgf),14700N(1500kgf),29400N(3000kgf) |

| Measuring range | 8 – 650 HBW |

| Testing Force Application Mode | Automatic (loading, holding, unloading) |

| Indenter objective lens conversion mode | manual operation |

| display usage | LED eight digital tube display |

| Microocular magnification | 20X |

| Test force holding time | 5~60s |

| Minimum division | 0.005 mm |

| Max sample height | 220mm |

| Max distance from head to body | 270mm |

| Voltage | AC 220V/50Hz  |

| Size | 753×550×236 mm |

| Total Weight | 123 kg |

Indication accuracy

| Standard Block | Indicating Error%(H) | Repeatability Error |

| ≤125 | ±3 | 0.035`d |

| 125<HBW≤225 | ±2.5 | 0.030`d |

| >225 | ±2 | 0.025`d |

H:Hardness of standard block `d: Indentation diameter(average)

Working Principle

Hardness is not a simple physical quantity, but a reflection of the

material elasticity, plasticity, strength and toughness. And

hardness test is the simplest mechanical testing method to

determine the metal material performance, also one of the important

means to judge the products quality.

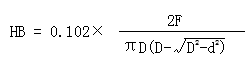

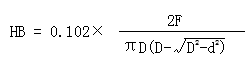

Brinell hardness test: Test force (F) is on the steel ball with

certain diameter(D) , pressed on sample surface. After a period of

time, cancel the force. The indentation diameter is get by

measuring with micrometer ocular, thus to calculate the average

pressure(N/mm²).Then we can get the Brinell hardness of the sample

as below:

Tips:F—Test force on steel ball,unit: N

D—Diameter of steel ball ,unit: mm

d—Indentation diameter,unit: mm

0.102—Rule coefficient

Features

- Suitable for measuring the surface is more rough cast iron, steel

and other non-homogeneous specimen Brinell hardness;

- Using electronic automatic loading system, remove the load weight;

- With ten test force, a wider range of tests, higher precision;l

- The control part is the closed-loop control system, which can

dynamically reflect real load changes.

- Modeling novel, strong structure,high reliability and operability ,

intuitive, high test efficiency;

- Equipped with excellent performance of the carbide indenter, high

hardness, wear resistance, good toughness, while high temperature,

corrosion resistance, to ensure that the instrument measured

standard, stable and reliable;

- Host stability is good, the workpiece surface quality and man-made

factors on the hardness of the test results less impact;

- Panel with two-color LED display, red for small gear, green for

large-scale force;

- Compliance with ISO 6506, ASTM E10-12, ASTM E-384, GB / T231.2, JIS

Z2243 and other relevant domestic and foreign standards.

Applied condition

- Cast iron, steel, non-ferrous metals, soft alloy of metal material

(please see table below);

- Hard plastic, bakelite and some nonmetallic material.

| Materials | Brinell hardness | 0.102F/D2 |

| Steel and cast iron | <140 | 10 |

| ≥140 | 30 |

| Copper and copper alloys | <35 | 5 |

| 35~130 | 10 |

| >130 | 30 |

| Light metals and their alloys | <35 | 2.5 |

| 35~80 | 5,10 |

| >80 | 10 |

| F:Test force(k) D:Head diameter(mm) |

Application field

- Metal processing industry quality control links

- Universities teaching and demonstration test

- The failure test of metal material

- The material hardness test of scientific research institutions

Working conditions

- Working Temperature:18℃~28℃;

- Relative Humidity:≤65%;

- Clean environment, no vibration;

- No corrosive media around.

Configuration

Standard Configuration | No. | Item | Quantity | Note |

| 1 | Main body | 1 | |

| 2 | 20×Lens | 1 | |

| 3 | φ2.5mm ball | 1 | |

| 4 | φ5mm ball | 1 | |

| 5 | φ10mm ball | 1 | |

| 6 | Small testing table | | Diameter 80mm |

| 7 | Large testing table | 1 | Diameter 200mm |

| 8 | V-shape testing table | 1 | For cylindrical sample |

| 9 | Standard Hardness Block HBW/3000/10(150-250) | 1 | |

| 10 | Standard Hardness Block HBW/1000/10(75~125) | 1 | |

| 11 | Standard Hardness Block HBW/187.5/2.5(150-250) | 1 | |

| 12 | Fuse wire(2A) | 3 | |

| 13 | Power Cable | 1 | |

| 14 | RS232 Cable | 1 | |

| 15 | Plastic dust cover | 1 | |

| 16 | Attached files | 1 | |

| 17 | Instrument case | 1 | |

Maintenance and care

- Each technical requirement of the instrument has already reached

the national standards before leaving factory. But its disassembly,

transportation or voltage after delivery might cause some data in

the instrument changed. So to make the electronic component in

normal operation to reduce the testing error, you can use test

force of 29400N(3000kgf) pressing times before starting the

instrument to eliminate the instrument deformation.

- The anti-interference component has been installed in the circuit

to ensure the transmission of the loading or unloading single of

the test force at all levels. At the same time, make sure no strong

interference source around when using the instrument, and power off

the instrument after finished the testing.

- All the screws and the caps have been fasten tightly before the

instrument leaving factory. However, the screw and cap may become

less crowded because that the screw lever for loading and unloading

are rotating all the time. If there is irregular noise, when the

screw lever rotating, please check and tightened the screw and cap

as the below figure shown.

- The surface of the tested parts should be smooth without dirt,

oxide, pits and impressive processing traces;

- The selection of the test force shall make the indentation diameter

within the prescribed range: 0.25D < d < 0.6D (D: indentation

diameter, D: steel ball diameter);

- The minimum thickness of the specimen shall be greater than 10

times of the indentation depth. After testing, the back of the

specimen shall not have visible deformation marks;

- The Instrument power supply shall be grounded reliably and equipped

with voltage-stabilizing device;

- If there is some slight noise during loading or unloading, it is

the loading mechanism making adjustment automatically, which is a

normal phenomenon.

- The instrument screw level and other movable surface should be

lubricated regular.

- When not in use for a long time, please cover the dust cover to

prevent dust into the instrument interior. And the hardness block,

indenter should be coated with antirust oil to prevent rusting

after using.

- Start using again after long time idling, please make testing after

preheating the electrical components.

- The eyepiece must be calibrated to zero for the first time using.

No need do zero calibration in subsequent testing.

- The accuracy of the reading microscope has been adjusted before

leaving factory. It is prohibited to disassembly without

authorization. Otherwise, it will reduce the reading accuracy of

the micro eyepiece.

- The storage and using of the reading microscope should avoid dust,

damp and corrosive gas environment;

- If there is dirt on the surface of the reading microscope lens,

please wipe it with soft absorbent cotton or lens paper. If there

is oil pollution, please wipe it slightly by the absorbent cotton

with industrial alcohol or ether.

- Don’t disassemble the instrument without authorization, maintenance

related matter, please contact MITECH after-sale service department

with 4000600280.