Mitech CO.,LTD. |

|

Mitech Magnetic Particle Flaw Detector CDX-Ⅲ magnetic inspection with simple process and low cost

Technical Parameters

Power input: AC220V, ±10%, 50HZ,5A

Power output: AC36V*2, 15A, can equip A, D, E, O four probes

Flaw detection speed: ≥6m/min

Probe temperature-rise: ≤60℃

Working conditions: when continuous working, magnetizing time≤3s, clearance time≥5s

Weight: about 7.0KG

Lifting: ≥45N(no less than 5kg)

Complex sensitivity: clearly show the artificial notch of type A 30/100 standard specimen

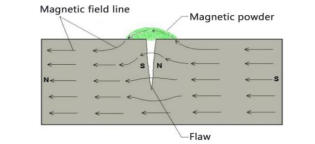

Working Principle

Put the workpiece in the magnetic field, connect electric to make it magnetized, if there are flaws(crack,slag), magnetic-curve will leakage on the flaws, when put magnetic powder on the workpiece, the magnetic field will catch the powder and pile up, in the proper light, we can see the marks and judge the position, size, shape and degree of the flaws.

Standard Configuration

| Configuration | No | Parts name | Type | QTY |

| Standard config | 1 | Main unit | CDX-Ⅲ | 1 |

| 2 | Type A magnetic yoke probe | 1 | ||

| 3 | Magnetic yoke line | 1 | ||

| 4 | Cable line | 1 | ||

| 5 | User’s manual | 1 | ||

| Optional config | 6 | Type D magnetic yoke probe | 1 | |

| 7 | Type E magnetic yoke probe | 1 | ||

| 8 | Type O magnetic yoke probe | 1 |

Maintenance

Mitech multifunctional magnetic powder flaw detector is precision detector, please pay attention to the following items:

Avoid Plugging and pulling the wire while the instrument is on.

After use, wipe out the oil on the surface to avoid rain, oil or other liquid into the machine.

Strong vibration should be avoided when moving the machine, it is usually kept in dry and ventilated place.

Regular charge is needed if not used for long, in case of damages caused by damp.

Wait for more than 5 seconds before reboot, or it may lead to error .

Make sure the contact is well before you press the probe button and release the button before finishing.Active joints should be regularly lubricated.

If the power light fails, it is mainly because the fuse damage or light problem.

If the magnetizing light fails, it is likely that the light bulb damage or relay fault. Thyristor damage is also possible.

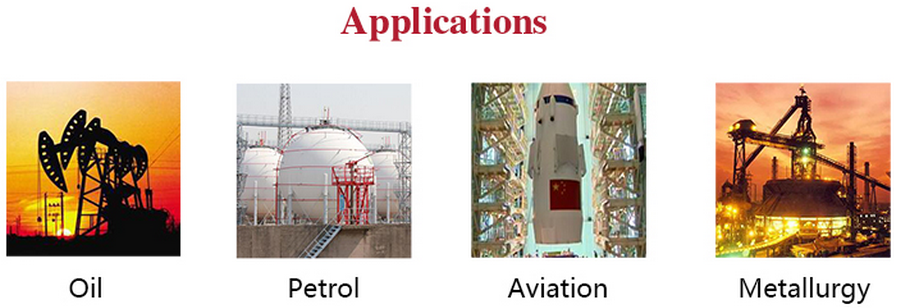

Function & Application

It is widely used in the industry of aircraft manufacturing, boiler and pressure vessel, electric, oil field, shipbuilding, turbine and combustion engine parts, mine, machinery, standard parts, oil pump, vehicle parts, bridging, chemical, railway, large mechanical components, steel structure equipment etc.

Types of probes

Types of probes

| Probe types | Parts name | Polar distance | Lifting | Weight |

| A | Fillet weld probe | 20-160mm | AC≥4.5kg,DC≥18kg | 1.8kg |

| D | Magnetic yoke probe | 60-120mm | AC≥5kg,DC≥18kg | 2.5kg |

| E | Cross yoke probe | 110mm | AC≥12kg | 3.0kg |

| O | Ring probe | Diameter 150mm | Magnetic field≥1800e | 2.5kg |