Mitech CO.,LTD. |

|

MITECH X-Ray Flaw Detector XXG-3005 with ceramic tube insert

Product Application

This machine is applicable for national defense, shipbuilding, petroleum, chemical industry, spaceflight, architecture and so forth industry lines to detect such materials as ship body, pipeline, high pressure container, boiler, airplane, vehicle, bridge, the welding quality and inner flaw of components, and the machining quality of various kinds of light metal, rubber, ceramic and etc.

Standard Configuration

| NO. | Name | QTY | Remarks |

| 1 | X ray flaw detector | 1 | |

| 2 | controller | 1 | |

| 3 | Connection cable(10 cores) | 1 | |

| 4 | Power cable(2 cores) | 1 | |

| 5 | Ground lead | 1 | |

| 6 | Fuse(3A) | 5 | |

| 7 | Attached files | 1 |

The Emission of X-ray

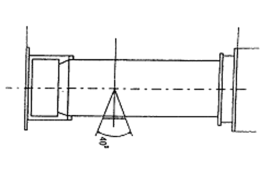

Figure 1 Figure 2

Figure 3 Figure 4

Figure 1:Glass tube circumferential target generator

Figure 2:Ceramic tube directional generator

Figure 3:Glass tube circumferential cone target generator

Figure 4:Glass tube directional generator

Generator Appearance

1 Gas pressure gauge 2 Cable line socket

3 Caution light 4 X ray generate area

5 Cooler fan

X ray generator combination, X ray tube, high voltage transformer and the insulation gas packaged together in bottled aluminum shell. Warning lights indicates the flaw detection system is in the ready state, and there will be x rays, during the production of X ray, warning light

Controller Appearance

1 Fault code and exposure chart 2 Standby light

3 HV light 4 Digital display

5 Time knob 6 KV presetting knob

7 “HV on” key 8 “HV off” key

9 Power switch 10 Connection cable socket

11 Power cable socket 12 Earthing wire

13 Fuse holder(3A)

The main parts in the controller are:KV control panel, mA control panel, microcomputer control panel, protection board, Controllable silicon high voltage module, LC filter, main,assistant silicon control inverter system. The inner controller has cooling fans, vent-windows on the side and back.