Mitech CO.,LTD. |

|

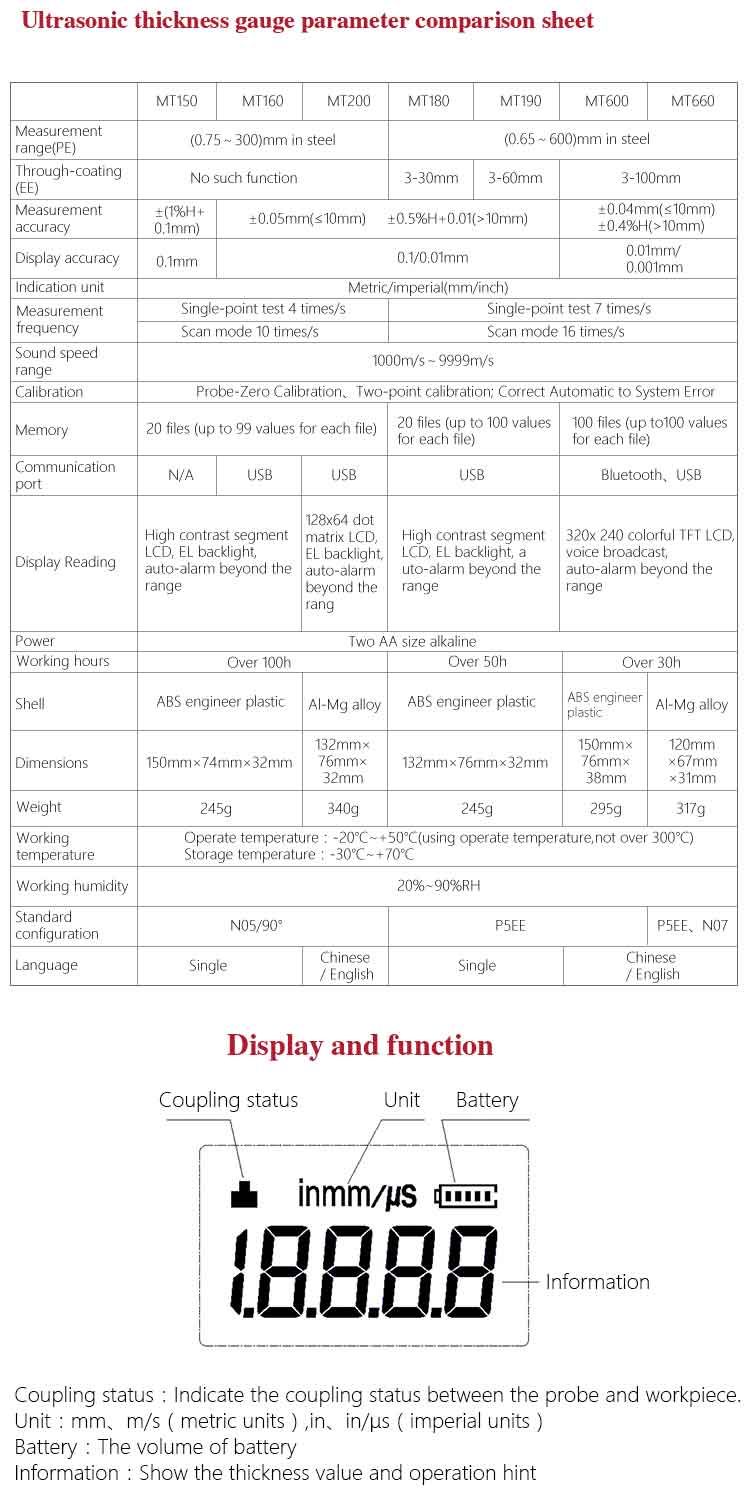

The model MT150 is a digital ultrasonic thickness gauge. Based on the same operating principles as SONAR, the instrument is capable of measuring the thickness of various materials with accuracy as high as 0.1/0.01 millimeters. It is suitable for a variety of metallic and non-metallic materials.

Measuring Principle

Measuring PrincipleThe digital ultrasonic thickness gauge determines the thickness of

a part or structure by accurately measuring the time required for a

short ultrasonic pulse generated by a transducer to travel through

the thickness of the material, reflect from the back or inside

surface, and be returned to the transducer. The measured two-way

transit time is divided by two to account for the down-and-back

travel path, and then multiplied by the velocity of sound in the

material. The result is expressed in the well-known relationship:

Where: H-Thickness of the test piece.

v-Sound Velocity in the material.

t-The measured round-trip transit time.

| No. | Item | Quantity | Note | |

| Standard Configuration | 1 | Main body | 1 | |

| 2 | Transducer | 1 | Model: N05 | |

| 3 | Couplant | 1 | ||

| 4 | Instrument Case | 1 | ||

| 5 | Operating Manual | 1 | ||

| 6 | Alkaline battery | 2 | AA size | |

| Optional Configuration | 1 | Transducer: N02 | See Table3-1 | |

| 2 | Transducer: N07 | |||

| 3 | Transducer: HT5 | |||

| 4 | Transducer:N05/90° | 1 | Only for MT160. | |

| 5 | High temperature couplant | 1 | ||

| 6 | DataPro Software | 1 | ||

| 7 | Communication Cable | 1 |

When the thickness gauge appears some other abnormal phenomena, please do not dismantle or adjust any fixedly assembled parts. Fill in and present the warranty card to us. The warranty service can be carried on. Keep it away from vibration, strong magnetic field, corrosive medium, dumpiness and dust. Storage in ordinary temperature. With Original packing, transport is allowed on the third grade highway.