Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

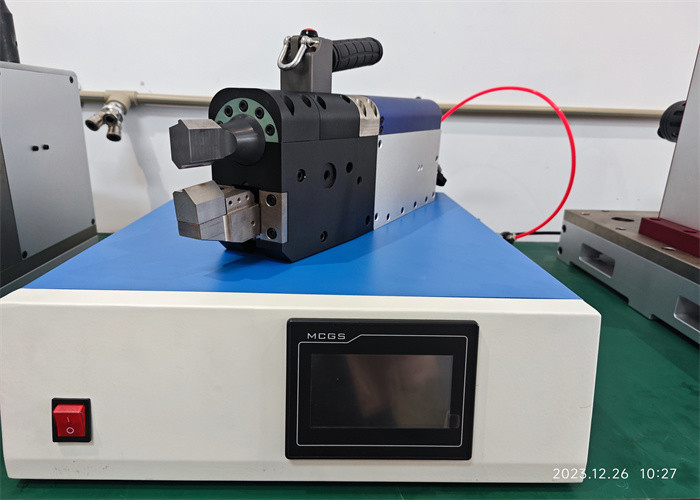

20kHz Ultrasonic Copper Tube Sealing Equipment Source Manufacturer

Copper Aluminum Tube Sealing and Cutting Machine

Description:

The ultrasonic copper pipe sealing machine for the process pipes of

refrigerators and freezers is an application of ultrasonic welding,

which can be used to seal and weld the process pipes, capillaries,

and heat pipes of compressors. The advantage lies in high welding

efficiency, low usage cost, no use of acetylene and welding rods,

and self fusion under pressure and friction. When the material is

in a semi molten state, it is pressed together, and excess copper

or aluminum pipes are cut off, saving pipe costs.

Working principle:

Qianrong's QR-F2030A series ultrasonic copper and aluminum tube sealing machine can simultaneously weld and cut copper tubes or aluminum tubes with a diameter of 0-10mm and a wall thickness of 0-5mm. It is mainly used in the refrigerator and air conditioner manufacturing industry to inject condensing agent. Welding of copper or aluminum tubes, capillary or spherical temperature sensors, and other ultrasonic welding of products requiring sealing of copper or aluminum tubes have changed the dirty process of labor-intensive industries and compressor injection of condensing agents. Compared with ordinary fire welding, ultrasonic welding can reduce the labor cost of customers by more than 60%. The operator can easily seal and cut the copper pipe injected with the condensing agent in one step, and save costs: quick joint And trimming machines, but also reduce the use of natural gas and environmental pollution caused by fire welding.

Specifications:

| Item No | QR-F2030A |

| Power | 3000W |

| Diameter of Tube | Φ2-12mm |

| Air Pressure | 0.05-0.9MPa |

| Frequency | 20KHZ |

| Voltage | 220V |

| Weight of horn | 26KG |

Drive system | Servo/Pneumatic |

Working Stroke | 30mm |

Advantages:

1. Human machine function interface: default parameter retrieval,

convenient parameter adjustment, can store multiple welding

schemes, supports data transmission and export

2. Reliable welding quality: Automatic amplitude compensation,

frequency protection, current protection, overload protection, and

high temperature protection for generators and transducers,

ensuring stable and reliable quality and high efficiency

3. Excellent processing equipment: The ultrasonic mold is made of

imported mold steel, which has good ultrasonic conductivity,

further improving quality, and high durability and wear resistance.

20kHz Ultrasonic Copper Tube Sealing Equipment Source Manufacturer

Copper Aluminum Tube Sealing and Cutting Machine