Hangzhou Qianrong Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

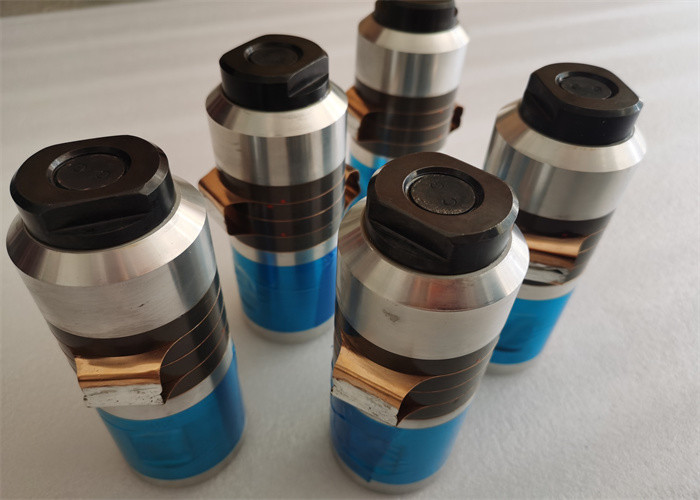

Piezoelectric Ultrasonic Ceramic with 15Khz Frequency Capacitor Range from 10nf to 11nf

Description:

The ultrasonic transducer converts the electrical or magnetic energy output by the ultrasonic generator into mechanical vibration of the same frequency. At present, the piezoelectric ceramic transducer is used on the mask machine. The piezoelectric effect of the material converts electrical signals into mechanical vibrations. The working principle of medical ultrasound transducers (ultrasound probes) is basically the same, and its interior usually contains an electrical energy storage element and a mechanical vibration system. When the transducer is used as a transmitter, the electric oscillation signal sent from the excitation power supply will cause the electric field or magnetic field in the electric energy storage element of the transducer to change. This change will affect the mechanical vibration system of the transducer through some effect. A driving force is generated to enter the vibration state, thereby driving the medium in contact with the mechanical vibration system of the transducer to vibrate and radiate sound waves into the medium. The process of receiving sound waves is just the opposite. The external sound waves act on the vibrating surface of the transducer, thereby causing the mechanical vibration system of the transducer to vibrate. With a certain physical effect, it causes the electric field or the energy storage element of the transducer. The magnetic field changes accordingly, causing the electrical output of the transducer to generate a voltage and current corresponding to the acoustic signal.

Specifications:

| Model | QR-6015-4BZG |

| Frequency | 15 khz |

| Output power | 2600 watt |

| Joint bolt | M20*1.5 |

| Ceramic disc Diameter | 60mm |

| Qty of ceramic discs | 4pcs |

| Capacitance | 10-11nf |

| Amplitude | 10 um |

| Application | Plastic welding machine |

Parameters:

| The columnar type NTK TYPE | ||||||||

Item No.

| Connect screw

| Ceramic dia (mm)

| Qty of Ceramic (pc) | Frequency (khz)

| Capacitance | power (W)

| ||

| Yellow | Grey | Black | ||||||

| 7015-4BZ | M20 X 1.5 | 70 | 4 | 15 | 12500-14000 | 17000-19000 | 2600 | |

| 6015-4BZ | M20 X 1.5 | 60 | 4 | 15 | 8000-10000 | 10000-12000 | 12500-13500 | 2200 |

| 6015-6BZ | M20 X 1.5 | 60 | 6 | 15 | 14000-16000 | 19500-21000 | 2600 | |

| 5015-4BZ | M18 X 1.5 | 50 | 4 | 15 | 12000-13000 | 13000-14300 | 15000-17000 | 1500 |

| 4015-4BZ | M16 X 1 | 40 | 4 | 15 | 10000-11000 | 10500-11500 | 700 | |

| 5520-4BZ | M18 X 1 | 55 | 4 | 20 | 10000-11000 | 10500-11500 | 14300-20000 | 2000 |

| 5020-6BZ | M18 X 1.5 | 50 | 6 | 20 | 18500-20000 | 22500-25000 | 2000 | |

| 5020-4BZ | M18 X 1.5 | 50 | 4 | 20 | 11000-13000 | 13000-15000 | 15000-17000 | 1500 |

| 5020-2BZ | M18 X 1.5 | 50 | 2 | 20 | 6000-6500 | 6500-7000 | 8000-9000 | 800 |

| 5020-4CZ | M18 X 1.5 | 50 | 4 | 20 | 11000-12000 | 13000-14000 | 14500-16000 | 1500 |

| 5020-4HZ | M18 X 1.5 | 50 | 4 | 20 | 11000-12000 | 1500 | ||

| 5020-4BL | M18 X 1.5 | 50 | 4 | 20 | 11000-12500 | 1500 | ||

| 4020-4BZ | 1/2-20UNF | 40 | 4 | 20 | 9000-10000 | 9500-11000 | 900 | |

| 4020-2BZ | 1/2-20UNF | 40 | 2 | 20 | 4800-5500 | 500 | ||

| 3820-4BZ | 1/2-20UNF | 38 | 4 | 20 | 6500-7500 | 800 | ||

| The columnar type NTK TYPE | ||||||||

Item No.

| Connect screw

| Ceramic dia (mm)

| Qty of Ceramic (pc) | Frequency (khz)

| Capacitance | power (W)

| ||

| Yellow | Grey | Black | ||||||

| 5025-2BZ | M12 X 1 | 50 | 2 | 25 | 5000-5600 | 7000-8000 | 500 | |

| 3828-2BZ | 1/2-20UNF | 38 | 2 | 28 | 3800-4300 | 500 | ||

| 3828-4BZ | 1/2-20UNF | 38 | 4 | 28 | 7600-8500 | 10500-12000 | 800 | |

| 3028-2BZ | 3/8-24UNF | 30 | 2 | 28 | 2700-3100 | 3400-3800 | 400 | |

| 3028-4BZ | M10*1 | 30 | 4 | 28 | 6000-7000 | 700 | ||

| 2528-4FZ | M8 X 1 | 25 | 4 | 28 | 3900-4300 | 400 | ||

| 2528-2FZ | M8 X 1 | 25 | 2 | 28 | 1950-2200 | 2200-2500 | 300 | |

| 3030-4BZ | M10 | 30 | 4 | 30 | 6200-6900 | 700 | ||

| 3035-2FZ | 3/8-24UNF | 30 | 2 | 35 | 2700-3100 | 500 | ||

| 3035-4BZ | M10 X 1 | 30 | 4 | 35 | 5000-6200 | 800 | ||

| 2535-2FZ | M8 X 1 | 25 | 2 | 35 | 1900-2200 | 400 | ||

| 2540-2BZ | 3/8-24UNF | 25 | 2 | 40 | 2000-2300 | 500 | ||

| 3040-4BZ | M10 | 30 | 4 | 40 | 5500-6200 | 1000 | ||

| 3050-4BZ | M8 | 30 | 4 | 50 | 5500-6200 | 600 | ||

| 1560-2BZ | M6 X 0.75 | 15 | 2 | 60 | 700-800 | 100 | ||

Ultrasonic transducer parts assembly precautions:

The main parts of the ultrasonic vibration system, such as transducers, horns, tool heads, etc., are connected by a central bolt.

1. Check that the contact surface should be smooth and free of scratches. If there are any scratches, use a metallographic paper with a number of zero or more to lightly polish. It is required to smooth the defect without damaging the flatness of the contact surface.

2. Clean the screws, screw holes and contact surfaces with a volatile, non-corrosive detergent.

3. Thoroughly clean the screws, screw holes and contact surfaces.

4. All connecting screw holes should be perpendicular to the contact surface.

5. Apply a thin layer of butter or Vaseline to the contact surface before tightening. Do not apply to the connecting screws and screw holes.

6. Carefully tighten the two parts. Adjust the appropriate tightening torque according to the specifications of the connecting screws. When possible, tighten it properly.

7. If you loosen the joint surface again, you should not see any scars.

8. The amplitude of the vibration system is evenly distributed by hand, no strange sound, no local severe fever.

9. After re-opening the joint surface after working for a period of time, there should be no signs of oxidation or ablation. Otherwise, the contact here is not good, and the ultrasonic energy is seriously lost here.

Piezoelectric Ultrasonic Ceramic with 15Khz Frequency Capacitor Range from 10nf to 11nf