Nanjing Zhitian Mechanical And Electrical Co., Ltd. |

|

Verified Suppliers

|

|

Quick Details

Product Name:80mm Clamp Connection Twin Screw Extruder Parts 68mm Center Distance Screw Barrel

Material: 38CrMoAla

Color: Metal

Packaging: Wooden Box

Lead Time: 30-60 days

Product Description

We can satisfy your different material needs:

According to appearance design,Closed Barrel,Feeder Barrel,Side Feeder Barrel,Venting Barrel,Combi Barrel.

According to the liner,With liner barrel,Without liner barrel.

According to Materical,

-For wear application:C liner;Cr26;Cr12MoV;W6Mo5Cr4V2;

-For corrosion application:38CrMoAla;Hac alloy;

-For wear and corrosion application:Nickel based alloy;316L,304;WR13,SAM26etc.

Through the understanding of customers,recommend the most valuable material.

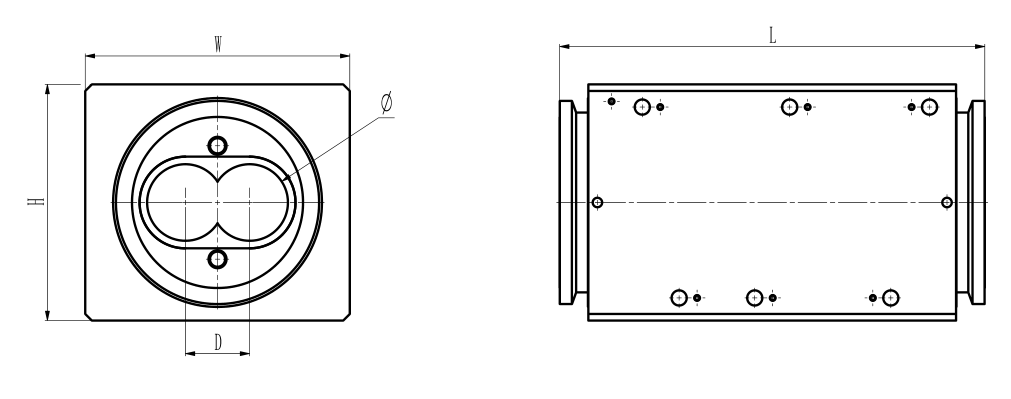

Barrel Dimensions

Screw Barrel Specifications Table

| ||||

| NO. | Model | L*W*H(mm) | Hole Diameter/Φ(mm) | Center Distance/D(mm) |

| 1 | 80(4D) | 300*280*250 | Φ81 | 68 |

| 2 | 80(6D) | 450*280*250 | Φ81 | 68 |

Production Process

| NO.1 Workblank

According to your request,Customing workblank,Adopts the high hardness 45# steel and high quaily 38CrMoAla. |

NO.2 Rough Machining

|  |

| NO.3 Finish Machining

|

NO.4 Barrel Inspection

|  |

| NO.5 Delivery

|

FAQ

How long does it take to get my products since I paid for them?

---According to yout order quantity,we will give you a reasonable delivery date.

Can I get the warranty of one year for free?

---If you need the warranty,you should pay for it.If not,do not worry ,we have confidence in our products.

How is your after-sale service?

---You will get our help in time as long as you find something wrong about our produces.Believe us,you deserve the best.

Are yuo responsible for the assembly?

---We will provide this service at your requst.