Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Efficiency Wear Resistance Shovel Convey Screw Element Twin Screw Extruder Parts

SK Single Flighted Screw Element

| ||

| Pression Angle | 30° | |

| Tooth | 20 | |

| Length | 96mm | |

| Derection | Right | |

| Dia. | 43 | |

| Model | 96/96 | |

| Material Feature | Wear/ Corrosion resistant | |

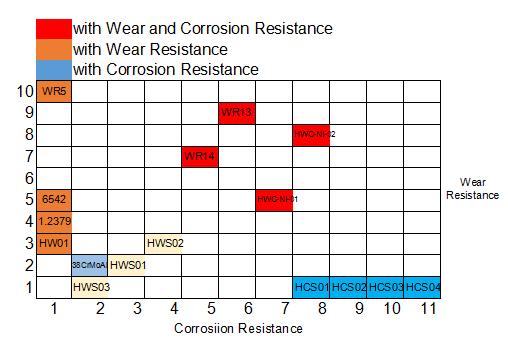

2. Materials:

For wear application:

* Normal material: HW01,HW02,HW03

* PM-HIP material: HWA

* Stainless Steel: HWS01, HWS02, HWS03

For corrosion application:

* Normal material: HC01

* Stainless Steel: HCS01, HCS02, HCS03, HCS04

For wear and corrosion application:

* PM-HIP material: HWC01, HWC02

* Ni-HIP material: HWC-Ni-01, HWC-Ni-02

3. Making process of screw elements

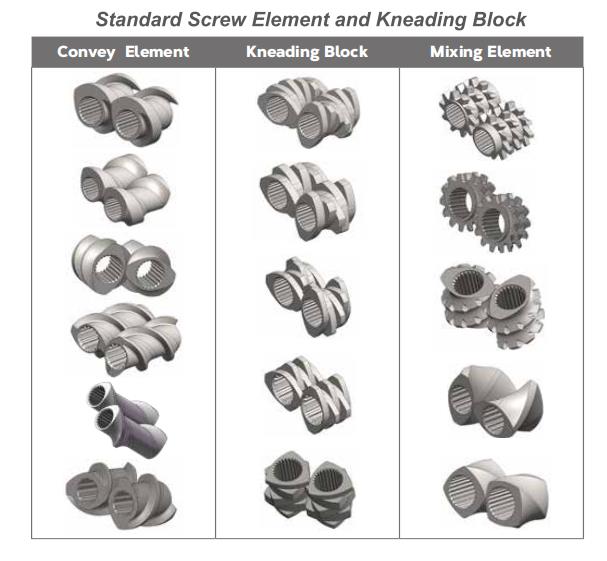

4. Type: All screw elements we produce

5. Heat treatment

heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves.

6. Production and Inspection of Equipment

Our factory is state-of-the art and spans over 20,000 square

meters. The factory houses more than 140 sets of different domestic

and foreign high precision production equipment, with the degree of

numerical control up to 95%.

7. Packing:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

a. Rust-proof oil processing,

b. Oiled paper packages,

c. Bubble wrap package,

d. Special foam packaging,

e. Packing,

f. Sealing.

8. Testing Reports

We will send Inspection reports for every our customer.

a.General Dimension Inspection Report

b. Material certificate for customer.