Joiner Machinery Co., Ltd. |

|

Verified Suppliers

|

|

DurableTwin Screw Elements GB Standard 3KB Kneading Block For Slight Shear

| Screw Design | Double-Screw |  |

| Surface Treatment | Sand blasting | |

| Materials | SAM10/CPM9V | |

| Model | 45°/5/60-3AB | |

| Layers | 5 | |

| Length | 60mm | |

| Screw Range | Φ 71 mm |

4. Our strength

They finish machining is carried out before heat treatment, and after heat treatment, the shape of the products are uncontrolled, so they cannot control precision. Our finishing is done after heat treatment, and can eliminate deformation of the parts in the heat treatment, then the precision of gear precision can reach level 6, achieving seamless connection.

5. Equipment

Screw elements making equipments - CNC thread grinding machine, CNC thread milling, CNC knead block grinding machine, CNC forming milling, 4-axis machining center, automatic deep hole grinding machine, CNC car, CNC surface grinding machine, CNC cylindrical grinding machine, CNC band saw, laser marking machine, vacuum quenching furnace, vacuum temper furnace and other 130 advanced equipment. After the raw materials come in, all processing procedures are completed internally.

6. Raw material guarantee

The company has been cooperating with domestic and foreign first-line brand material suppliers for a long time, and has a strict quality control and performs regular audits and inspection of the factory (elemental analysis, metallographic analysis, ultrasonic flaw detection, etc.) to ensure a 100% qualified status.

7. Packing Details:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

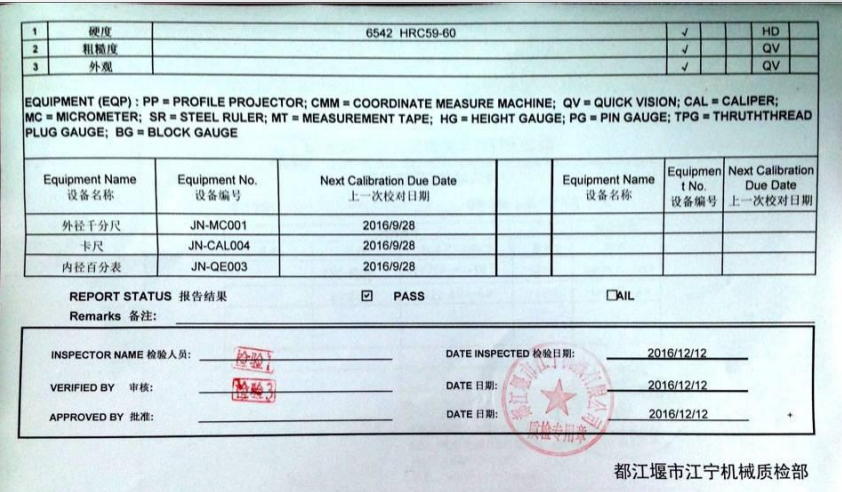

8. Testing Reports

We will send Inspection reports for every customer.

a. General Dimension Inspection Report

b. Material certificate.

9. Why choose us?

(1) Total solution of highly wear-resistance and

corrosion-resistance problems;

(2) Expert of engineering design and consulting,

(3) Advanced manufacturing capabilities and technology,

(4) Lean production management.

(5) Top quality products with high cost performance.