Shenzhen Yideyi Technology Limited Company |

|

Printed Circuit Boards Design Fabrication And Assembly SMT PCBA

Shenzhen Yideyi Technology Limited Company is a professional PCB&PCBA Solution Service Provider specializing in one-stop service from PCB, components purchasing, PCB assembly to complete products building. Our services include PCB fabrication, PCB assembly,raw material purchasing, components purchasing, test, logistics and other value-added services. According to the customer demand, the flexibility to adjust the production schedule, the maximum meet customer and market demand.

Our products are widely used in meter, medical, solar energy, mobile, communication, industrial control, power electronics,security, consuming, computer, automotive, aerospace, military and so on. Over 75% of our products are exported to Europe, North America, Japan and other Asia Pacific countries. Based on many years of development, we have high-qualified management team, experienced R&D team and skilled employees,and possess advantaged supply chain, commitment to quality,and dedication to our customers service. Encouraging innovation and keeping improving. Besides achieving corporate and customer values, we also create a favorable atmosphere for employees to achieve personal values.

We provide every member with broad space for individual goals. "Science and technology innovation win-win world,We provide the best products and services." Highlights of guarantee: High quality Materials guarantee:All PCBs are made of high quality Class A laminates and all components are high quality and authorized. High Quality products guarantee: All PCB and PCB assembly are tested and full inspected. Timely Delivery guarantee: Lead time is strictly controlled and met for both normal and quick turn orders.

To free your hands for marketing and sales, we take care everything rest beside from components procurement, SMT assembly, THT assembly, cable assembly, box build and shipping, until goods knock you door. Total solution and one stop services!

SMT PCBA capabilities:

• SMT assembly including BGA assembly

• Accepted SMD chips: 01005,BGA,QFP,QFN,TSOP

• Component height: 0.2-25mm

• Min packing: 0201

• Min distance among BGA : 0.25-2.0mm

• Min BGA size: 0.1-0.63mm

• Min QFP space: 0.35mm

• Min assembly size: (X*Y): 50*30mm

• Max assembly size: (X*Y): 350*550mm

• Pick-placement precision: ±0.01mm

• Placement capability: 0805, 0603, 0402, 0201

• High pin count press fit available

• SMT capacity per day: 800,000 point

DIP capability:

• A-8 of semi-assembly work line with 3 set wave soldering machines

• B-4 of high/low-temperature burn-in test ovens for the burn-in tested required products

• All products are 100% inspected and tested during the DIP process

Requested informations for PCBA:

1. Components list

(a) Specification, brand, footprint

(b) To short the lead time, please kindly advise us if there is any acceptable components substitution.

(c) Schematic if necessary

2. PCB board information

(a) Gerber files

(b) PCB board processing technic

3. Testing Guide & Test Fixtures if necessary

4. Programming files & Programming tool if necessary

5. Package requirement

Production processes:

Material Receiving → IQC → Stock → Material to SMT → SMT Line Loading → Solder Paste/Glue Printing → Chip Mount → Reflow → 100% Visual Inspection → Automated Optical Inspection (AOI) → SMT QC Sampling → SMT Stock → Material to PTH → PTH Line Loading → Plated Through Hole → Wave Soldering → Touch Up → 100% Visual Inspection → PTH QC Sampling → In-Circuit Test (ICT) → Final Assembly → Functional Test (FCT) → Packing → OQC Sampling → Shipping

Why Choose Us?

1. Your inquiry related to our products or prices will be replied in 24hrs.

2. Well-trained and experienced staffs to answer all your enquires in fluent English

3. OEM&ODM, we can help you to design and put into product.

4. Distributorship are offered for your unique design and some our current models

5. Protection of your sales area, ideas of design and all your private information

Our Electronic Design and Development Capability

1, Schematic Design. Based on your specification and requirement, our electronic engineer will provide a solution to reach your expect function.

2, Enclosure Design. We’ve an industrial design company partner work with us in this field. Professional, stylish, nice and clean design concept will be handed to you. Of course, all will be based on easy production, less cost and less problem during production.

3, PCB Development. Based on the schematic and certification request, our experienced engineers will provide you the best solution of it.

4, Components Procurement. Cost less and good quality.

5, PCBA Assembly.

6, Enclosure prototype and production.

7, Full product Assembly.

8, Provide Test Method.

SMT PCBA technical Capacity

| SMT | Position accuracy:20 um |

| Components size:0.4×0.2mm(01005) —130×79mm,Flip-CHIP,QFP,BGA,POP | |

| Max. component height::25mm | |

| Max. PCB size:680×500mm | |

| Min. PCB size:no limited | |

| PCB thickness:0.3 to 6mm | |

| PCB weight:3KG | |

| Wave-Solder | Max. PCB width:450mm |

| Min. PCB width: no limited | |

| Component height:Top 120mm/Bot 15mm | |

| Sweat-Solder | Metal type :part, whole, inlay, sidestep |

| Metal material:Copper , Aluminum | |

| Surface Finish:plating Au, plating sliver , plating Sn | |

| Press-fit | Press range:0-50KN |

| Max. PCB size:800X600mm | |

| Testing | ICT,Probe flying,burn-in,function test,temperature cycling |

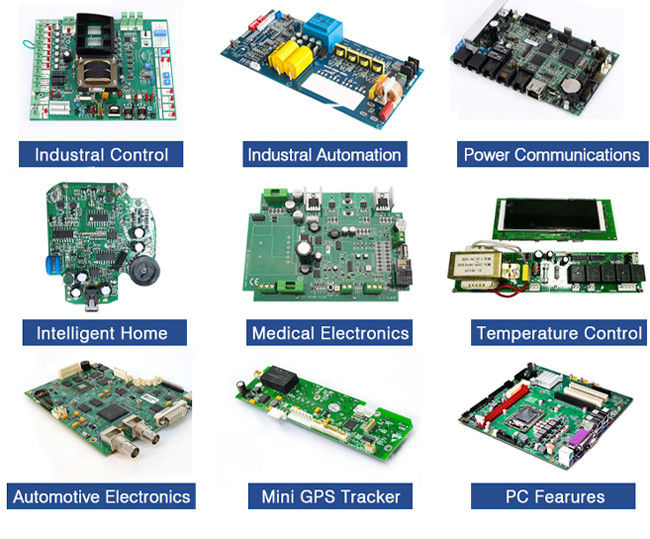

PCBA Application:

FAQ:

Q2. What file formats do you accept for PCB PCBA production?

Gerber file: CAM350 RS274X PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

Q3. How many kinds of moulds can you make? Only make the moulds?

We can make many kinds of moulds, such as plastic injection moulds,

stamping moulds, die casting moulds and silicone rubber moulds.

Besides, we also can produce the final parts for you.

Q4. How to ship the PCBAs?

For small packages, we will ship the boards to you by

DHL,UPS,FEDEX,TNT. Door to door service! For mass production, we

could ship by air, by sea.