Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. |

|

Manufacturer Oil Well Pump Tungsten Carbide Ball Valve Seat With Long Life Time

Precision machined carbide balls and valve seats

1. High strength, high wear resistance, high precision, good

temperature resistance and good corrosion resistance.

2. Mainly used for the sealing of valves of oil pumps in petroleum

industry`s containing wells, viscous oil wells, sea oil wells and

high pressure sulfur resistant oil wells, etc.

3. Balls and seats are used with compatible cemented carbide valve

seats.

4. The finished surface, tolerance standard have reached the

standards of the machine industry: G5, G10, G16, G40 and G100 of

JB/T 9145-1999.

5. Precision machined cemented carbide balls of other grades and

specifications are also available based on customers` demands.

6. Compatible high precision valve seats can also be made.

Application

1. Valve balls and seats are widely used in oil fields.

2. Valve Ball and Seat performance directly affects the use effect

and service life of the sucker rod pumps.

3. Each ball-and-seat combination is vacuum tested to ensure a

perfect seal is obtained in all positions of contact.

Advantages

1. 100% virgin raw material

2. Well hardness & resistance

3. Many sizes & types available

4. ISO9001: 2008 certificate

Grade List

| Grade | WC% | CO% | Hardness (HRA) | Desnity (G/M³) | T.R.S (Mpa) | Metallographic analysis | Application |

| YG6 | 94% | 6% | 91 | 14.6-15.0 | 1700 | A02B02C02 | Widely used in all kinds of hardware industry, valve, bearing, die casting , punching, grinding measurement. |

| YG6X | 94% | 6% | 92 | 14.6-15.0 | 1450 | A02B02C02 | Widely used in all kinds of hardware industry, valve, bearing, die casting , punching, grinding measurement. |

| YG8 | 92% | 8% | 89 | 14.4-14.8 | 1800 | A02B02C02 | Widely used in valves,bearing, die casting , punching, grinding

measurement,hardness tester, petroleum, chemical industry,

aeronautics and astronautics. |

Grade and applicaton for valve seat

| Grade | Co (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) | Application |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wear-resistant |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 | |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 | |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 | |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 | |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 | |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Application |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 | Corrosion-resistant |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 | |

| XN300 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2100 | |

| XN301 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2400 |

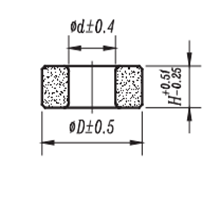

| Seats dimension (mm) | ||

| D | d | H |

| 19.48 | 11.68 | 12.7 |

| 22.66 | 13.97 | 12.7 |

| 28.22 | 17.02 | 12.7 |

| 33.81 | 20.96 | 12.7 |

| 36.09 | 24.38 | 12.7 |

| 41.43 | 26.92 | 12.7 |

| 48.79 | 33.27 | 12.7 |

| 74.93 | 43.18 | 19.05 |

| Ball dimension (mm) | ||

| D±1.27(mm) | ||

| 15.88 | ||

| 19.05 | ||

| 23.83 | ||

| 28.58 | ||

| 31.75 | ||

| 34.93 | ||

| 42.88 | ||

| 57.15 |

Specifications of Valve Ball & Valve Seat for API Sucker Rod Pump

Model/Item | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

| Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

| Seat-ID ± 0.050 (± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

| Seat-OD +0.000/-0.005 (+0.00/-0.13) | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

| Seat-H +0.020/-0.010 (+0.51/-0.25) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 19.05 (0.750in) |

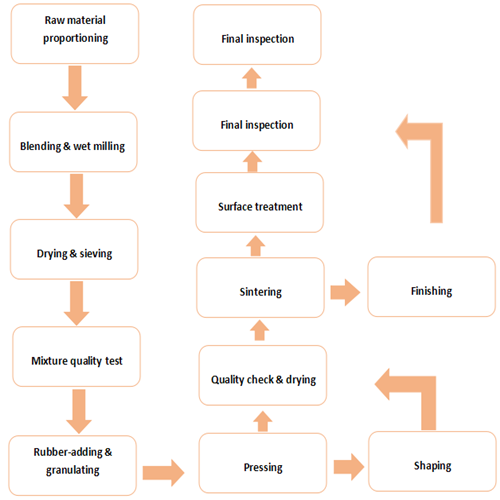

Production Process

FAQ

Q1: How can I place order?

A1: You can contact us by email about your order details, or place

order on line.

Q2: How can I pay you?

A2: After you confirm our PI, we will request you to pay. T/T (HSBC

bank) and Paypal, Western Union are the most usual ways we are

using.

Q3: What’s the order procedure?

A3: First we discuss order details, production details by email or

TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into

production. After we get the deposit, we start to process the

order. We usually need 7-15 days if we don’t have the items in

stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been

settled, we start to prepare the shipment for you.

Q4: How do you take care when your clients received defective

products?

A4: replacement. If there are some defective items, we usually

credit to our customer or replace in next shipment.

Q5: How do you check all the goods in the production line?

A5: We have spot inspection and finished product inspection. We

check the goods when they go into next step production procedure.

A5: Can I get the samples?

Q5: Sure, contact us directly.