Reliable Cold Forging Die , High Precision Strong Beam Die Mold

Component

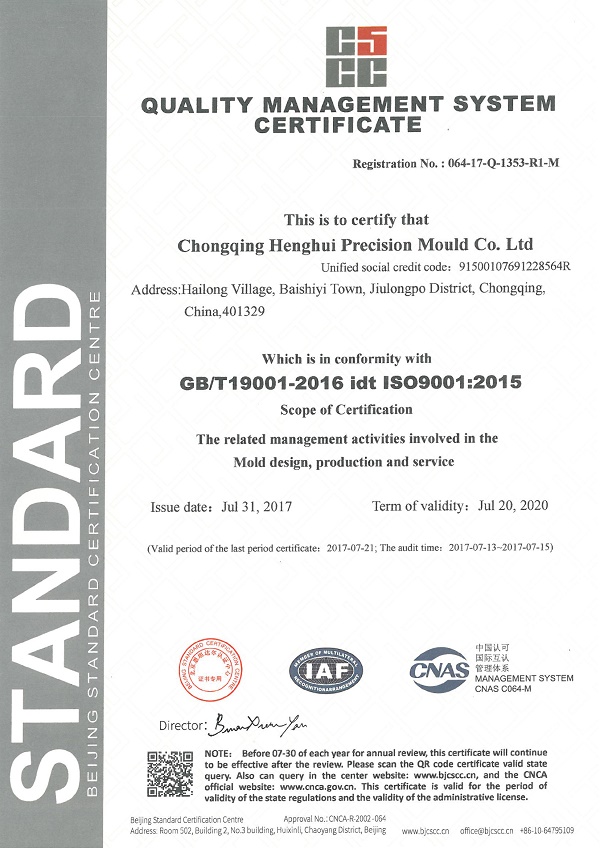

Henghui a experienced Injection mold, Mold Component & related production maker

It is highly suggested that you send the drawings or

samples for our reference, and we will reply you ASAP, Thank you.

Specification of Mold Component

Item | Mold Component | Available materials | (1)Aluminum alloy:A380,ADC12,AlSi12,A356 (2)Zinc alloy:Zamak3,Zamak5,ZnAl4Cu1 (3) Aluminum profile:AW6063,AW6061 (4)Stainless steel:A303,A304 and A306 (5)Carbon steel:35,40 and 45 (6)Plastic:ABS,PP,POM,Nylon | Surface treatment | Plating,Painting,Powder coating,Anodization,Ball blasting

Vibration grinding,Polishing,Brushing | Dimension | Part size: aluminum alloy---maximum: 350 x 300 x 150mm

minimum: 20 x 15 x 5mm Zinc alloy

---maximum: 350 x 300 x 150mm

minimum: 5 x 5 x 2mm Part weight: Aluminum alloy---Maximum: 2,500g

Minimum: 5g Zinc alloy

--- Maximum: 5,000g

Minimum: 2g | Application | Circular loom manufacturers,Auto part companies and electronic factories, Lighting companies,Rehabilitation equipment companies,Street lamp companies, Lock companies,Oil pump companies | Package | Plastic Tray/Carton/Wooden pallet |

|

Our Factory

Advanced machines and technology talented persons guarantee

the high output, high quality and high

speed production of Henghui.

Henghui Provides work members with considate care and

excellent working environment.

Why Choose Us

Our advantages | 1.High quality | 2.Reasonable price | 3.On time delivery | 4.Good After-sale service | 5.Strict quality control | 6.All the mold are automotic. | We will offer you | 1.In-time response on letters, telephone calls or fax | 2.In-time supply the quotation and Mold Component designs | 3.In-time communication on the technical points | 4.In-time sending pictures for the Mold Component machining progress and Mold Component finishing schedule | 5.In-time Mold Component test and sample delivery | 6.In-time Mold Component delivery. |

|

Our Logistics for Mold Component Shipping

Usual we choose the following ways to ship our Mold Component, if

there is any other choices

or requirements, we also welcome.

Sample Charge

1.Sample charge:According to your design.Sample time:3-5 days

2.Sample charge: For Existing samples.Sample time:1 day

Mold Component Ordering Guide

General Order information

In order to provide our clients the best service,We have set up customer management platform.

Standing in our clients’s way,

we know our clients’ demands and the problems we need to solve.

Drawings or samples provided | We get the drawings or samples from our clients. | R&D | We support customer R&D. Make the files or improve the design if you needed. | Quotation | According to the drawings or samples | Mold Component design | Send Mold Component design for confirmation within 3 days after getting Mold Component charge | Mold Component making | Start to make the Mold Component after design confirmed | Test-run | After Mold Component is finished, we’ll test it and get samples | Sample confirmation | Send the free samples to client to make sure perfect | ( Mold Component modification) | (If the sample is not ok, we’ll modify the

Mold Component for free, Then send free samples to you again...until meet your demands) | ( Mold Component delivery) | (Shipping Mold Component out if no need to injection plastic parts,

packed by wooden case by see or by air, according to client’s requirements) | Plastic Injection Service | Start to high-volume production with the ordered

Mold Component |

|

FAQ

Q1::Are you a factory or trading company? | A1:We are a factory, Henghui has 7,000 square meters of manufacturing plants and R&D bases | Q2:Where is your factory located? How can I visit there? | A2:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District, Chongqing City, China. All our clients, from home or abroad, are warmly welcome to visit us at anytime! | Q3:What is the material of your products? | A3:The material is DC53,SKD11,D2,SKH-9,SKH-51, or as our clients’ requirements. | Q4: The maximum press your factory have available ? | A4: Our factory has 30T,60T,160T punching machines | Q5::How does your factory do regarding quality control? | A5: Quality is priority. Henghui people always attach great importance to quality controlling from the very beginning to the very end. All the

Mold Component, the QC measure with three-D measuring equipments regularly. |

|

Packaging & Shipping

Usually, we choose the following ways to transport our molds, if

you have other options or requirements, we are also welcomed.

Exhibition

The global demand for fasteners is constantly increasing, driven

by the strong global economy and a steady growth especially in the

construction, aerospace, automotive and white goods markets. The

broad and versatile scope of application for fasteners and fixings

continues to create opportunities for manufacturers and suppliers

of these technologies. With ever changing requirements and

advancements in various industry sectors, new business

opportunities are opening for the future. So Henghui

participated in many international exhibitions.