Jiangsu TOM Intelligent Equipment Co., Ltd., |

|

Verified Suppliers

|

|

FXX-4A PLC Controlled Automatic Capping Machine For Plastic Bottle Within 1L

summarize:

This machine is a new generation of rotary capping machine developed on the basis of the working principle and operation mode of the machine of France's serac company, combined with the specific situation of packaging equipment in China. Its performance and qualified rate of screw cap are the most advanced models in China. The function of catching cap and releasing claw can be comparable with similar products in Europe and America. This product is a mature model of our company which has been tested by the market. Many manufacturers without R & D experience in the market are surveying and mapping products of our company, whose stability is worrying and meets the requirements of GMP certification.

Major Parameters:

| NO. | Name | Parameter |

| 1 | Suitable Bottle | 100ml-1L |

| 2 | Machine weight | About 1000kg |

| 3 | Suitable cap | Φ30-75mm H20-40mm |

| 4 | Equipped power supply | AC380V;50HZ |

| 5 | Power | 3.5kw |

| 6 | Equipped with air source/consumption | 0.6MPa clean and dry air source; 200L/min |

| 7 | Capacity | 3000 bottles/hour for 1L |

Machine's Main picuture:

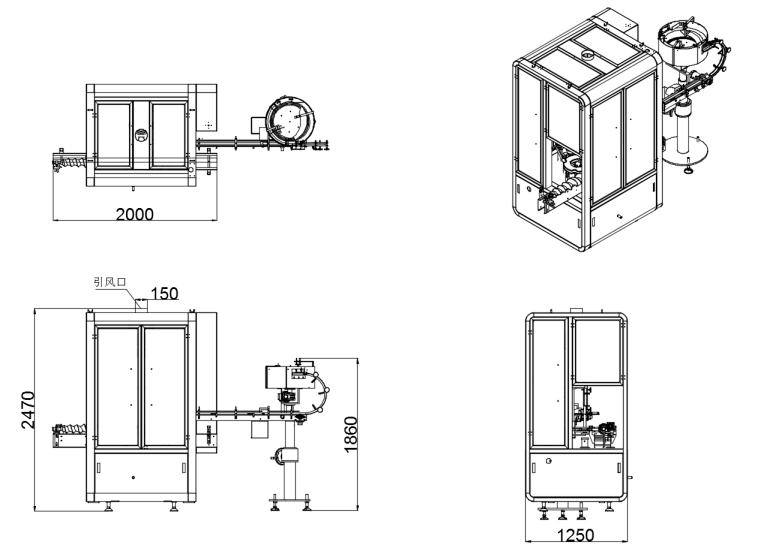

Machine’s detailed three vision drawings:

Detailed Introduce:

1. When the bottle entering star wheel detects that the bottle is in, the cap-in cylinder release caps, enter into star wheel, find the cap to screw the cap at the position of the star wheel, and automatically rotate to the starting position after completion;

2. The speed of cap elevator, cap sorter, bottle feeding, capping and bottle conveying can be adjusted by frequency conversion and can be adjusted separately in the touch screen, so as to avoid bottle falling and bottle blocking caused by inconsistent speed and improve working efficiency.

3. For the template with quick installation mode, the corresponding template can be removed by rotating the knob 90 ° to change the specification

The independent motor drives the capping machine. Compared with the multi gear operation of the conventional old capping machine, this capping machine has higher efficiency.

After the capping is completed, the detection device is used to detect the skew cap, no cap and no aluminum foil, and the defective products are eliminated by the swing cylinder elimination device to ensure that the products are 100% qualified

The reverse cap is automatically removed to ensure the qualified rate:

Applicable bottle type:

Packaging & shipping:

Company Overview--Jiangsu Tom Group