Wuhan Global Metal Engineering Co., Ltd |

|

Verified Suppliers

|

|

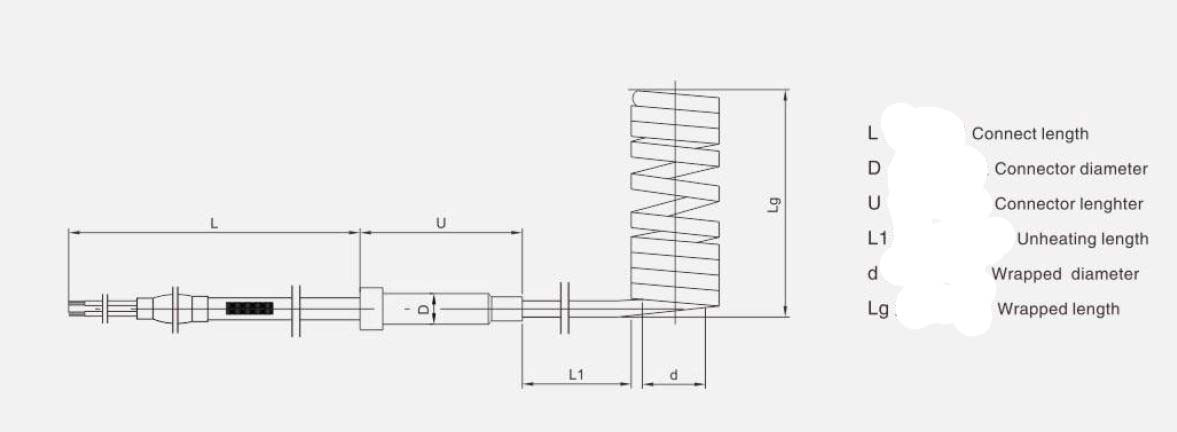

Micro Coil Heater for Injection Mold Hot Runner System

1. Micro Coil Heater Brief Introduction

Wuhan Global Metal hot runner coil heater use Germany heater wire,

United States high-purity magnesium oxide material, and strict

process technology. There are various cross section and size

for choice, such as square, round and flat, provide

high-performance electric heater for heating hot runner mold and

other fields.

Heater maximum temperature up to 650 ºC, the integration of

temperature thermocouple for the precise temperature control, can

provide K, J, E thermocouple, blasting and blackening surface

treatment, also can provide bright surface.

2. Micro Coil Heater Characteristics

a. Very good performance of the heating uniformity in the heating

area.

b. The inside insulated cover, same as the German GC.

c. High insulation (more than 500M ohm) and high pressure

resistance (1000V above), can meet special requirement if customers

need.

d. The moisture-proof can be IP65, suitable for working in bad

condition.

3. Micro Coil Heater Parameter.

Spring coil heater (H series) | 3.2x1.8 | Φ1.8 | Φ2.5 | 4.2x2.2 |

Voltage | 220V,230V,240V | |||

Power tolerance 115W-200W | +/-10% | |||

Power tolerance 201W-2000W | +5%-10% | |||

Out jacket length | 30mm~280mm | |||

inside jacket diameter | 10mm~42mm | |||

Unheating length | 45mm | |||

Max power density | 9W/cm² | |||

Heating Length tolerance | +/-0.05mm | |||

Unheating length tolerance | +/-2.5% | |||

Tolerance ID d ≤20mm | 0.05mm~0.10mm | |||

Tolerance cross section | +/-0.10mm | +/-0.15mm | ||

Thermocouple | K,J,E | None | K,J,E | |

Material | 304,321,316 | |||

Maximum working temperature | 650℃ | |||

Die electrical strength | 600V | 800V | ||

4. Copper Heaters Coil Application

Hot Runner Nozzles & Bushings.

Hot runner Injection moulds

Injection & Blow Moulding Machine Nozzles.

PET prefrom & Thin wall container Moulds.

Hot Runner Manifolds.

5. Packing Information

6. Transportation