Wuhan Global Metal Engineering Co., Ltd |

|

Verified Suppliers

|

|

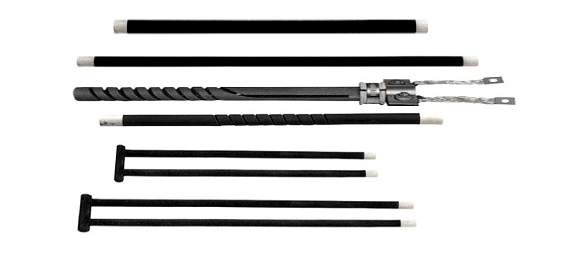

Silicon Carbide Rod SiC Heater Element for Industrial Heating

1. Introduction

SiC Heater Element is a kind of non-mental high temperature electric heating element.It is made of selected high-purity green silicon carbide as raw material which is made into blank and silicon crystal under high temperature of 2400ºC. It mainly used for furnance heating temperature from 600C-1600ºC. It is widely used in electric heating of glass, chemical, electronic material etc.

| SiC Content | 98.5% |

| Type | Air Heater |

| Tube diameter | 8mm to 50mm |

| Voltage | 110-480V |

| Warranty | 1 Year |

| Material | Silicon Carbide (SiC) |

| Working temperature | 600C-1600C |

| Application | Furnace heating |

2. Types

1. U Type SiC Heater Element

2.W Type SiC Heater Element

3.Spiral Type SiC Heater Element

4.Double Spiral Type SiC Heater Element

5.GC ( Dumb bell type )and GD (Rod)Type SiC Heater Element

3. Features

1. withstand high temperature as high as 1600℃

2. high strength and excellent shock resistance

3. heat source is free of noise and air pollution

4. anti-oxidization, anti-corrosion

5. easy to installation and maintenance

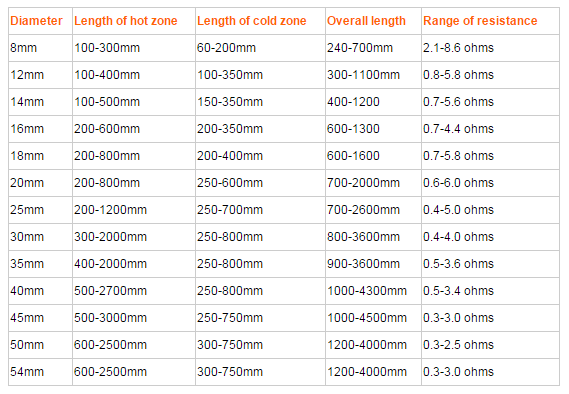

4. specification

5. Tips for usage

1. Be protected against damp during storing or installing to ensure the performance ;

2. Divided before assembling. The tolerance of the resistance of each one cannot exceed by 10% each other;

3. Be careful when using and maintaining;

4. When operating the electric furnace at the beginning, the voltage should be increased slowly and cannot be fully loaded at once. Otherwise the larger current will be resulted in the damage of heater.

5. When heater is damaged and need to be changed, the resistance of new ne should follow the increasing resistance. If many are damaged or resistance increased too much, heater should be changed.

6. Packing and Delivery

1. Packing

Export carton packing box for small qty;

Export wooden packing box for large qty.

2. Shipping

Fedex/DHL/UPS/TNT for samples, Door-to-Door;

By Air or by Sea for batch goods;

Customers specifying freight forwarders or negotiable shipping methods;

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.