3in1 H Beam Welding Machine Single Arc Twin Wire High Efficient

Welding

Quick Details

- Web height up to 1500mm, thickness up to 40mm; Suitable for light

duty beam;

- H-beam combination workstation is used for H-beam or T-beam

assembly, welding and straightening;

- Save space and economize workshop; shorten the production time and improve the efficiency;

- Economize the investment of crane equipment and operator;

- American Lincoln DC-1000,NA-3S single arc twin wire welding power;

- Japan Mitsubishi PLC controller;

1. Introduction

H-beam combination workstation is used for H-beam or T-beam

assembly, welding and straightening. It centralize the

assembly, welding and straightening functions on one machine which

saves space and economize workshop.Reduce workflows: shorten the

production time and improve the efficiency. Economize the

investment of crane equipment and operator.

2. Main Parameters

Model | ZHJ15 |

Suitable web height mm | 200—1500 |

Suitable web thickness mm | 6—32 |

Suitable flange width mm | 200—800 |

Suitable flange thickness mm | 6—40 |

Straightening thickness mm | 6—35 |

Fillet height mm | ≦8 |

Work-piece length mm | 4000—15000 |

Feeding speed m/min | 0.2—2 (VFD) |

Input conveyor m | 3conveyorss, each 2.6m (one powered) |

Output conveyor m | 11.5m, including lift conveyor |

Machine power kW | 18.1 |

Power supply | AC380V, 50HZ, 3P or tailor made |

Above are our standard models and parameters, and it can be designed and manufactured on request. |

*

We reserve the right to alter specifications without prior notice.

3. Main features

The standard models of our H-beam combination workstation for

assembly, welding and straightening has the

following features:

- Robust all steel fabrication with stable structure and good rigidity, and no deformation after long time using;

- Synchronous clamping and centering system for web and flange;

- Japan Mitsubishi PLC controller;

- The whole system is using the PLC, and the speed of straightening, assembly and welding is the same;

- American Lincoln DC-1000,NA-3S single arc twin wire welding power;

- Flux feeding and recovery machine;

- Heat treatment to main welding parts after welding; sand blasting treatment to main welding parts before

- painting;

- All motion parts have lubrication system;

- Main electric elements are ABB/Siemens brands;

- Lifting lug;

- Standard color:

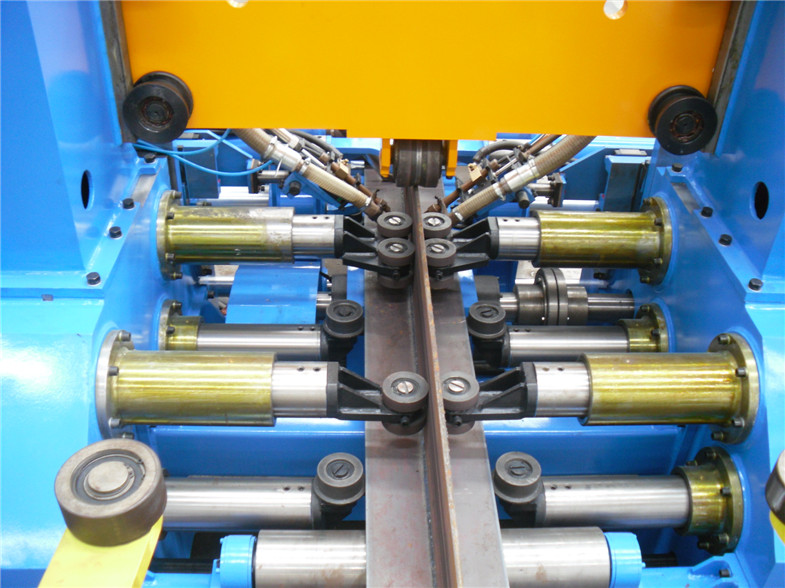

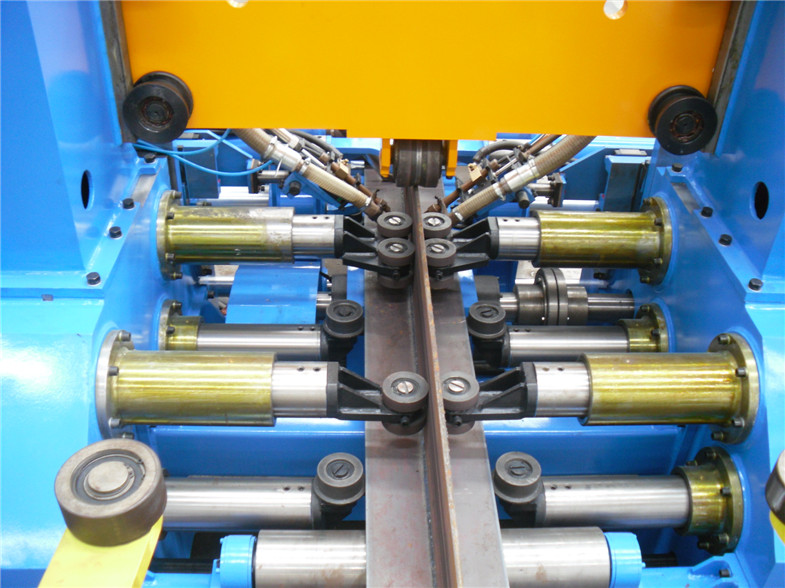

4. Reference photo

5. Comparative advantage

- ISO9000&CE certified;

- International warranty;

- Punctual delivery;

- Professional and experienced engineer team to ensure the advanced

design about structure and electric;

- Experienced and skilled workers to care for each work flow from

material cutting, welding, grinding to final assembly and testing

to ensure high machine quality;

- Professional and experienced after sale service team to guarantee

quick and satisfied installation, commissioning or service;

- Optimum materials and outsourcings to ensure the best performance;

- Commissioning and testing before delivery;

- Factory inspection is encouraged;