TS Automation Technology co Ltd |

|

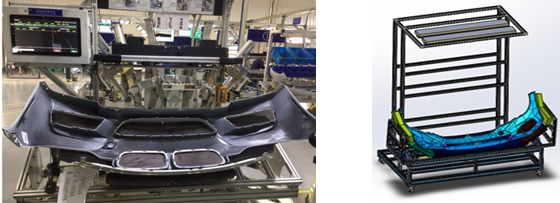

Bumpers Products Solution

♦Bumper process flow:

Injection molding,Spraying,Welding,Punching,Assembly etc;

♦ Processing equipment:

Injection molding automation equipment ,automatic spraying,Punching welding equipment(special machine/flexible),Punching bonding,Assembly fixture;

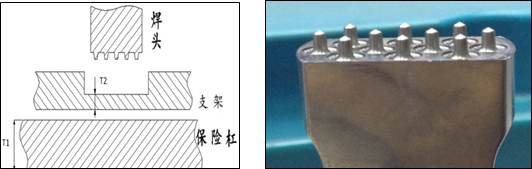

♦ Radar bracket ultrasonic penetration welding

Bumper design parameters

a),Welding spot area T1:3.5-4.0mm(High bright black productT1′:3.8-4.2mm)

design parameters of fog lamp bracket

b), Welding spot area thinkness thinning processing,T2:1.2-1.5mm(High bright black product T2′:1.0-1.2mm).

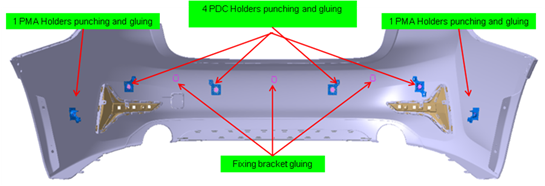

♦Ultrasonic punching and welding machine

Configuration: The whole system is equipped with ultrasonic generator and transducer made in Germany,

Siemens control system, FESTO or SMC pneumatic components.

Successful case: Geely GE11 GE12 SX11 SX12 etc.

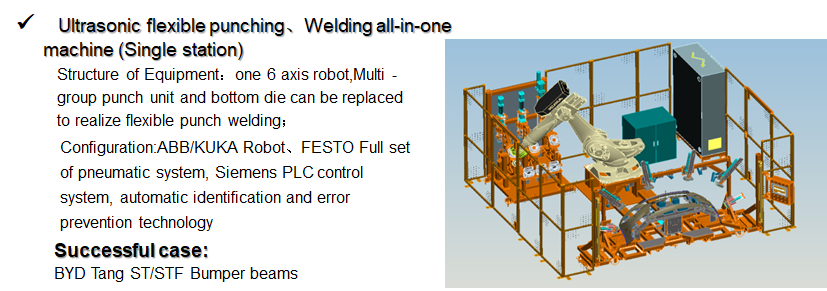

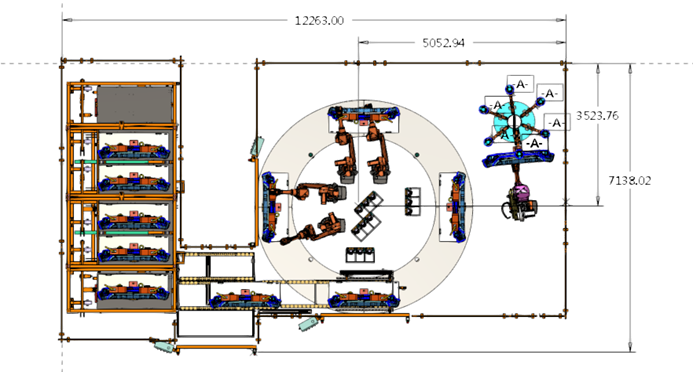

Flexible bumper punch,Welding multi-molding

Feature:

1,Multiple robots,4 stations to finished punching and welding;

2,Turntable,production line automation change the mold,flexible punching,flexible welding;

3,Can produce 3 sets of products at the same time,Achieve just-in-time JIT production,4 set of molds for each other .

4,Easy to process,Easy to operation maintenance;

5,6 holes 6 welding +16 single spot welding,48s/pcs,inculding pick up,change mold about 15s;

The equipment can record and trace the inspection information of each assembly part (error prevention function)

Package Detail:

♦Outside package:Standard wooded package.

♦Inner package:Stretchy film and plastic film for humidity.

♦Also we can package according to your requests.

Delivery Detail:

♦This non-standard machines, customized machines according to

clients' specific requirements,it will be 30 to 50 working days

after order.

Our Serve

Pre-Sales Service:

♦Inquiry and consulting support.

♦Detailed professional product quotation

♦View our Factory.

After-Sales Service

♦Training how to instal the machine, training how to use the

machine.

♦Engineers available to service machinery overseas.

♦Technical support by phone,e-mail,whatsapp and skype.If you have

any problems,we will within 12 hours to solve it.

♦Provide english version manual and operation video CD disk.

♦1 year guarantee for whole machine.

♦If you need any component of the machine,we will provide the best

price for you.

FAQ

♦If we don't know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training

until you can use machine freely.And if you are busy ,we will have

the special engineer to your country,but you need to bear some

fee,like tickets, hotel and meal.

♦How about your after-sales service?

We offer you 24 hours service phone,skype.

♦How about your guarantee period?

One year.If you have any questions during this time,we will solve

it for free.

♦How long is your delivery time?

Generally it is 15-20 days if the goods are in stock. or it is

20-30 days if the goods are not in stock, it is according to

quantity.