BEIJING KOREA TECHNOLOGY CASTER CO.,LTD |

|

What details should be paid attention to in the machining

process?

NC machining refers to a machining method of machining parts on NC

machine tools and controlling

the displacement of parts and tools with digital information. It is an effective way to solve the

problems of changeable parts, small batch, complex shape and high precision, and realize efficient

and automatic machining. Generally speaking, the process procedures of NC machine tool machining

are consistent with those of traditional machine tool machining. However, because NC is one-time

clamping and continuous automatic machining to complete all turning processes, some matters

needing attention in NC machine tool machining.

1. Select the appropriate tool

Tool life is closely related to cutting parameters. When making

cutting parameters, we should first

select a reasonable tool life, and the reasonable tool life should be determined according to the

optimization goal. Generally, there are two kinds of tool life: the highest productivity tool life and the

lowest cost tool life. The former is determined according to the goal of minimum man hours per piece,

and the latter is determined according to the goal of minimum process cost. The tools used in CNC

machine tools often use tool materials suitable for high-speed cutting (such as high-speed steel and

ultra-fine grained cemented carbide)and indexable blades.

What do we need to pay attention to in the machining process of NC

machine tools?

2. Select reasonable cutting parameters

The economical and effective machining method must be to select

reasonable cutting conditions. The

operator shall select the cutting speed according to the processed material, hardness, cutting state,

material type, feed rate, cutting depth, etc. The most suitable processing conditions are selected on

the basis of these factors. Regular and stable wear is the ideal condition to reach the service life.

3. Select the appropriate fixture

(1) Ensure that the coordinate direction of the fixture is

relatively fixed with that of the machine tool.

(2) Coordinate the dimensional relationship between parts and

machine tool coordinate system to

reduce positioning error.

4. Determine processing route

Machining route refers to the motion track and direction of the

tool relative to the part in the machining

process of NC machine tool.

(1) The machining accuracy and surface roughness requirements shall

be ensured;

(2) . the processing route shall be shortened as far as possible to

reduce the tool idle travel time.

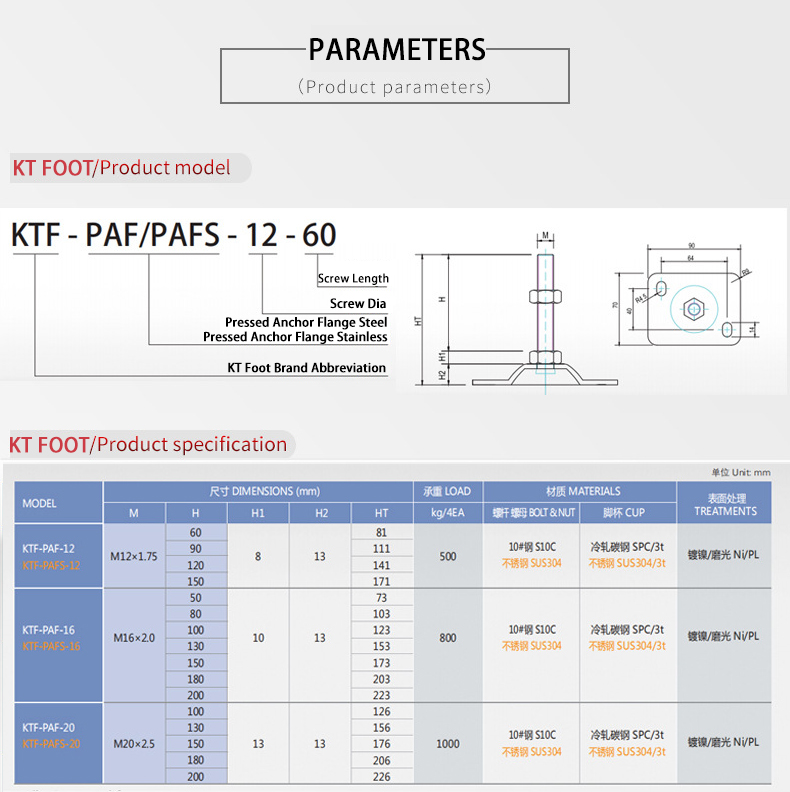

Heavy Duty Adjustable Feet Parameter

Heavy Duty Adjustable Feet Size

Heavy Duty Adjustable Feet Material

| Name | KTC Foot |

| Model | KTF-TR |

| Type | Ultra Heavy Duty Purpose Type Series |

| Application | Machine tools, Automatic facilities, Special machine, LCD

equipment, Semiconductor equipment, Heavy duty equipment |

Heavy Duty Adjustable Feet Describe

Heavy Duty Adjustable Feet Scope of application

KTC (Bejing Korea Technology Caster Co., Ltd.) was founded in 2007. KTC is a modern

company specialzingin the production of multi function &high quality CASTER and

KT FOOT based on best design and design technology.

The company is headquartered in Niulanshan Industrial Zone,Shunyi District, Beijing. KTC

adopts international advanced production testing equipments, professional intelligent

production management system and professional design flow. Now the company produces

multi function & high quality production, such as KT CASTER and KT FOOT, among which

high quality of height adjusting CASTER,shockproof type CASTER, high quality of height

adjusting CASTER, shockproof type CASTER,high load CASTER and level adjusting FOOT

are widely used in the world's advanced automation equipment and semiconductor e

quipment industry.

In order to manufacture the world's highest level of products,KTC

use the best processing

technology and equipment. And KTC continuously launches world top level of new products.

KTC's s also has set up a branch in Korea, so it is favored by theusers of various fields around

the world.