Suntek Electronics Co., Ltd. |

|

Verified Suppliers

|

|

ISO13485 FR4 94v0 Rigid And Flex PCB For medical parts ROHS UL certifiled

Suntek Contract Factory:

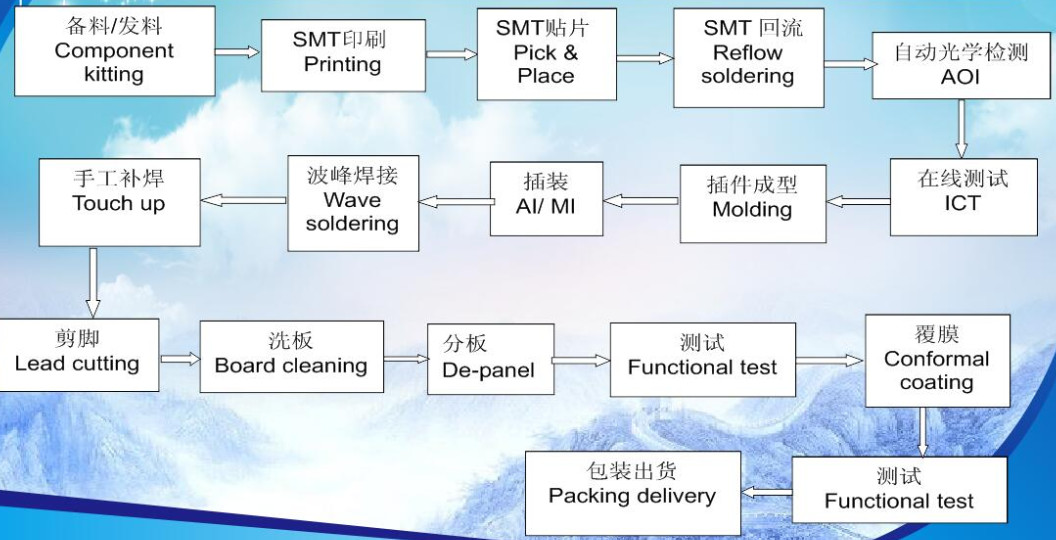

We provide one-stop solution for PCB assembly and cable assembly,both turnkey and consignee solutions,with strict adherence to RoHS regulations. Our products experience include consumer electronics,industrial products,telecommunications, medical equipment etc.No matter it is quick-turn prototype,short-run or high volume mass production.

Capabilities overview:

Specifications | Details |

Material type | FR-1, FR-4, CEM-1, aluminum clad |

Material thickness ( mm) | 0.4, 0.6, 0.8, 1.0, 1.2, 1.6, 2.0 |

Layer count | 1 to 8 Layers |

Max. Board size | 23.00” x 35.00”(580mm*900mm) |

IPC class | Class II, Class III , Class 1 |

Annular ring | 5 mil/side or Greater (Min. Design) |

Finish plating | Solder(HASL), Lead Free Solder(HASL), ENIG (Electroless nickel immersion gold), OSP, immersion silver, immersion tin, immersion nickel, hard gold, other |

Copper weight | 0.5OZ-2OZ |

Trace/space width | 3 Mils or greater |

Drill clearance | 0.1mm(laser drilling) |

Plated slots | 0.036 or greater |

Smallest hole (finished) | 0.1mm or greater |

Gold fingers | 1 to 4 Edge (30 to 50 Micron Gold) |

SMD pitch | 0.080” - 0.020” - 0.010” |

Solder mask type | LPI Glossy, LPI-Matte, SR1000 |

Solder mask color | Green, red, blue, black, white, yellow |

Legend color | White, yellow, black, red, blue |

CNC route point | Any |

Minimum route width | 0.031” |

Scoring | Straight lines, jump scoring, panel edge to edge, CNC* |

Body gold | HARD*, IMMERSION* (up to 50 MICRON GOLD) |

Data file format | Gerber 274x with embedder aperture |

FAB. Drawing format | DXF, HPGL, DWG, PDF, Gerber |

E.T testing | Flying probe, single sided, 1up plate, clamp shell, net list |

Counter sink/counter bore | Available up to 0.250 Diameter |

Control impedance | Yes |

Blind vias/buried vias | Yes |

Peelable mask | Yes |

Carbon | Yes |

Flex

Flexible PCB, also known as flex prints or flex circuits, is a special type of circuit board that you can bend into the desired shape. They are widely used for high-density and high-temperature applications. The flex designs are composed of polyimide or a transparent polyester film as a substrate material that comes with high heat resistance which makes it a right fit for solder mounting components.

A flexible circuit comes with a conductive layer of traces made up of copper that is combined with a polyimide dielectric layer. The thickness of the copper conductive layer can vary from 0.0001’’ to 0.010’’ and the thickness of the dielectric material can range from 0.0005’’ to 0.010’’. An adhesive is required to bond the conductive copper layer to the substrate; while sometimes vapour deposition is equally handy to attach the copper with the substrate.

The material selection for making flexible circuit boards is a bit tricky and depends on many factors including chemical and mechanical resistance, current, temperature, capacitance, and types of flexing.

The flexible designs are more reliable as they come with fewer interconnections that ensure fewer solder joints and contact crimps. And these circuits require less space due to their flexible bend capability and they cover only 10% of the area compared to rigid circuit boards.

Service Offerings:

Innovative Rigid-Flex Processes

Premium Material Sets

Rigid-Flex with HDI

Loose Leaf Construction

Oversized Panels

Layer counts to 40+

Heat Sink Application

Applications:

The flexible circuit boards are a right match for applications that require better performance, high accuracy, precision, and regular flexing. Applications of flexible circuit boards include:

Cameras

Antilock brakes

Fuel pumps

Ultrasound probes

Semiconductor test

Medical devices

Motion systems

Satellites

Avionics

Battery packs

Manufacturing devices

Airbag systems

Packing and Shipping:

Flexible PCB Assembly Packaging and Shipping

Packaging:

The Flexible PCB Assembly product will be packaged in a sturdy cardboard box to ensure safe transportation. The box will be sealed with tape to prevent any damage during shipping.

The product will also be wrapped in bubble wrap to provide extra protection against potential impact and vibration during transit.

Each box will be labeled with the product name, quantity, and handling instructions to facilitate easy identification and handling.

Shipping:

The product will be shipped via a reliable and trusted courier service to ensure timely and secure delivery to the customer.

The shipping address and contact information will be double-checked to ensure accurate delivery. The product will be insured during transit to protect against any unforeseen events.

A tracking number will be provided to the customer once the product has been shipped, allowing them to track their order and ensure its safe arrival.

Upon delivery, the customer will be required to sign for the package as proof of receipt.

Our Target

We are always trying to supply competitive price,high quality,quick-delivery products.

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.