Active Member

|

[China]

Address: 1604#, Yangming Sicence & Technology Industry Center, No.855 Nanhu Avenue,Wuxi city, Jiangsu, China

Contact name:Alfred

Jiangsu Lebron Machinery Technology Co., Ltd. |

|

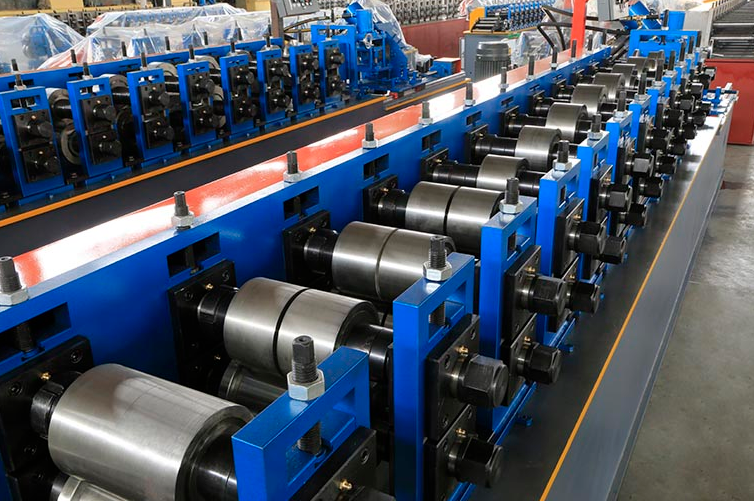

5.5KW Fully Automatic Steel Stud And Track Roll Forming Machine Siemens PLC Controlled

1. Description of stud and track roll forming machine

The studs and track shapes mainly include C shape, U shape, W shape, C shape with holes, L shape, etc. These products are widely used in many kinds of buildings, such as industrial factories, civilian buildings, and wallboard for the attached part product. They have the advantages of pretty appearance, durable using and so on.

In the modern building system, metal c stud and u tracks are great inventions in steel building projects, and that makes drywall stud and track roll forming machines, or even all the lightweight or light gauge steel frame roll forming machines highly popular in the international.

Due to the technology monopoly, there are rarely Chinese manufacturers can provide steel framing solutions for lightweight or light gauge steel buildings, but for a drywall stud and track roll forming machine production, Chinese manufacturers are no doubt reliable.

2. Major technical parameters of stud and track roll forming machine

| No. | Item | Specification |

| 1 | Can Formed Material | GI, AL strip, or coil |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 50Hz 3Phase (or custom) |

| 4 | The thickness of the sheet (mm) | 0.6-1.2mm |

| 5 | Material width(mm) | As your drawing |

| 6 | Yield strength | 550Mpa max |

| 7 | The size of the roll forming machine | 3500mmx1200mmx1400mm |

| 8 | Speed | 20-30m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

| 11 | Material of rollers | Cr12 steel quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubishi |

| 14 | Total power (kW) | 8kw |

| 15 | Power of the hydraulic system | 4kw |

| 16 | Power of main molding core | 4kw |

| 17 | Transmission | Chain with gears |

3. Major components of stud and track roll forming machine

| Components for stud and track roll forming machine | |||

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

4. Installation service

a. After the machine arrives at the destination, the seller will send a technician to the buyer’s factory to install the machine if the buyer wants. The buyer needs to provide some technicians to assist with the installation work.

The installation period is around 5 days. The buyer should have been prepared for the steel sheet, foundation position the machine before the seller’s technician's departure.

The buyer should arrange the accommodation, food, and traffic in the destination

Training period: 2 days. (we can supply training on the operation spot if buyer needs)

Within 3 months after the arrival of the goods at the port of destination, if there is no installment requirement from the Buyers, the goods should be counted as up to standard. The inspection standard is based on the technical standard signed by both parties and our company standard.

5. Quality Guarantee

The Seller shall guarantee the goods with materials and workmanship in accordance with the required on the drawings, brand new, unused, and correspond in all respects with the quality, specification, and performance as stipulated in drawings and guarantee a good smooth operation for 12 months after the date of shipment (except consumables). This guarantee excludes the parts that require normal plant maintenance. The guarantee is strictly limited to the repairing and the replacing of the mechanical parts supplied by us found to be defective provided that failure has occurred during the ordinary use of the equipment and it is not accepted and claim due to damage to people, property, or loss of production.