Jiangsu Lebron Machinery Technology Co., Ltd. |

|

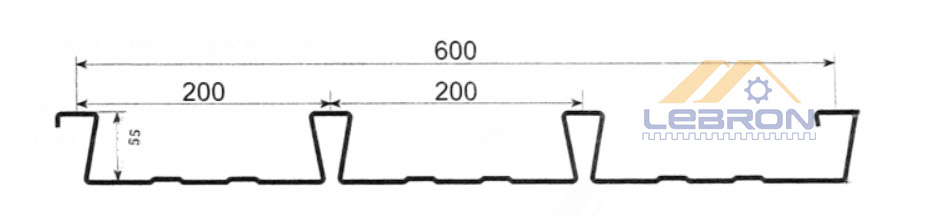

YX 55 200 600 Type Floor Deck Roll Forming Machine Siemens PLC Omron Encoder Automatic

1. Description of floor deck roll forming machine

Steel floor decks are widely used in power plants, power equipment companies, automobile showrooms, steel structure workshops, cement warehouse, steel structure office, airport terminal, railway station, stadium, concert hall, grand theater, large supermarket, the logistics center, the Olympic stadium and the steel structure of the stadium.

To meet the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time.

It can be used to lay special-shaped steel plates on multi-layer floors and flow construction of layered concrete slabs

There are many standard metal deck or steel deck profiles that a steel deck roll forming machine is technically capable to produce, and these deck sheets are widely used in a variety of applications.

Steel deck roll forming machines have been designed for the production of various types of metal decks which are usually applied for roofing and floor industries, and sometimes for bridge construction as well.

2. Main technical parameters of floor deck roll forming machine

| No. | Item | Description |

| 1 | Suitable Material | Hot-dipped galvanized steel coils |

| 2 | Thickness of Material | 0.8mm-1.5mm |

| 3 | Roller Stations | 20 stations |

| 4 | Diameter of Shaft | 90mm |

| 5 | Material of Shaft | 45# steel |

| 6 | Material of roller | 45#steel with quenching treatment and coated with hard chrome 0.05mm thickness |

| 7 | Forming speed | 12~15m/min |

| 8 | Main Power | 15KW |

| 9 | Overall Dimension | 13.5mx1.5mx1.3m |

| 10 | Weight of the machine | Approx. 12 Tons |

| 11 | Cutting | hydraulic cutting |

| 12 | Material of Cutting Blades | Cr12 steel |

| 13 | Hydraulic Power | 4KW |

| 14 | Control system | Panasonic PLC, Inverter, CHNT transformer, and Omron encoder |