Jiangsu Lebron Machinery Technology Co., Ltd. |

|

C U Channel Blue Color Metal Stud And Track Roll Forming Machine Full Automatic

1. Description of stud and track roll forming machine

Now, in the modern building project, metal studs and tracks are more and more widely used. The drywall stud and track roll forming machine, or even all the lightweight or light gauge steel frame roll forming machines are highly popular in the international.

A stud and track roll forming machine has been designed for the automatic manufacturing of the metal c stud or u track continuously for light gauge or lightweight steel building systems.

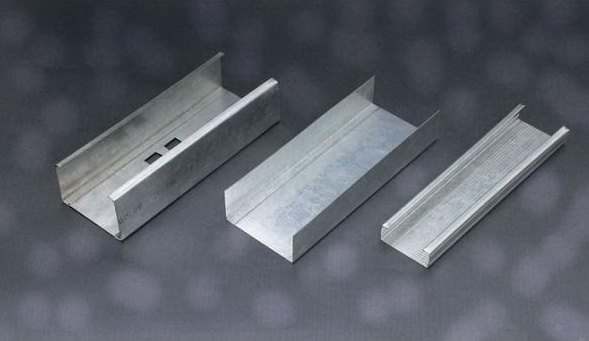

The Stud and Track Roll Forming Machine is used for producing various different shapes of studs and tracks. Such as C shape, C shape with holes, L shape, etc. These products are widely used in many kinds of industrial factories, civilian buildings, and wallboard for the attached part product. It has the advantages of pretty appearance, durable using and so on.

The complete Stud and Track Roll Forming Machine including the Decoiler, Main Roll Forming Machine, The PLC control system and Ran-out tables. The roll forming machine equipped with the computer control system. You just need to program in the computer the piece and length you need, then the roll forming machine produces it automatically. The machine is easy to operate and operate stably.

2. Main technical parameters of stud and track roll forming machine

| Technical parameters of stud and track roll forming machine | ||

| 1 | Name of commodity & specification | light gauge steel machine |

| 2 | Main motor power | 5.5 KW |

| 3 | Hydraulic motor power | 3 KW |

| 4 | Hydraulic Pressure | 10-12MPa |

| 5 | Voltage | 380V /3phase/ 50 HZ (can custom) |

| 6 | Control System | PLC Delta Converter |

| 7 | Main Frame | 300mm H-Beam |

| 8 | Backboard Thickness | 18mm |

| 9 | Chain Size | 20mm |

| 10 | Feeding Material | color steel coils |

| 11 | Feeding Thickness | 0.3-1.2mm |

| 12 | Productivity | 12m~20m/min |

| 13 | Roll Station | 11 or custom |

| 14 | Roller Diameter | 70mm |

| 15 | Roller material | 45# steel |

| 16 | Cutter material | Cr12 , quenched |

| 17 | Cr-Plating Size | 0.05mm |

| 18 | Overall Size | 3000×800×1000mm |

| 19 | Total Weight | 2T |

3. Main technical parameters of stud and track roll forming machine

| No. | Item | Quantity (Set) |

| 1 | Manual Uncoiler | 1 |

| 2 | Guiding Platform | 1 |

| 3 | Coil Strip Leveler | 1 |

| 4 | Main Machine of Roll Forming | 1 |

| 5 | Electric-Motor | 1 |

| 6 | Cutting Device | 1 |

| 7 | Hydraulic Station | 1 |

| 8 | PLC Control | 1 |

| 9 | Supporter Table | 1 |

4. FAQ

1. Q: Are you a manufacturer, trading company?

A: We are a manufacturer, and we have built up our company since 2007.

2. Q: Where is your factory located?

A: Our factory address is: No. 551, the Zhenze West Road, Huazhuang Street, Binhu District, Wuxi City, Jiangsu, China

3. Q: How can I get to your factory?

A: Our factory is near Shanghai Airport, we can pick you up at the airport. Or you can by plane direct to Wuxi airport. We can pick you up.

4. Q: If I will need to stay in your place for a few days, is that possible to book the hotel for me?

A: It’s always my pleasure, hotel booking service is available.

5. After-sale service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you install and debug the machines well. Buyer should pay $60 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during the guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t be forced by human are excluded).

C. Training

During the installation and adjustment of the equipment, our engineers shall provide the training to

buyer’s personal request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation, and non-standard safety items, testing material and etc.