Jiangsu Lebron Machinery Technology Co., Ltd. |

|

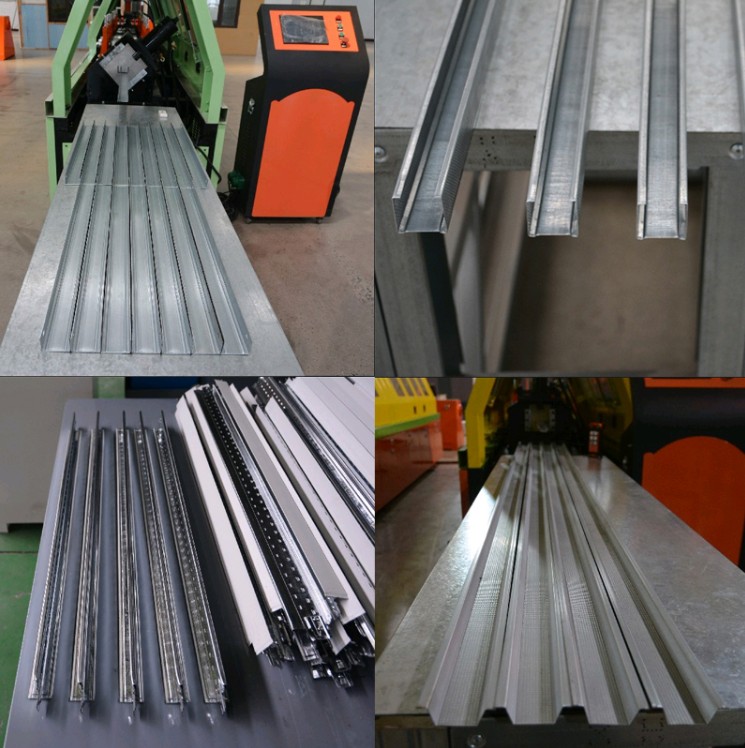

Furring Channel Cold Roll Forming Light Steel Keel Roll Forming Machine PLC Control

1. Description of furring channel roll forming machine

The furring channel light keel roll forming machine has been designed for the manufacturing of hat shaped furring channels used to build lightweight or light gauge steel buildings.

Being one of the roll forming machines for the production of lightweight or light gauge steel frames, a furring channel roll forming machine or hat channel roll forming machine produces metal furring channels or hat channels continuously and automatically from galvanized steel of 0.6-1.2mm thickness as main components of steel roof trusses on lightweight or light gauge buildings.

The metal furring channels or hat channels are produced from thin galvanized steel (0.6-1.2mm thickness) by roll forming machines and a metal furring channel or hat channel roll forming machine, like other lightweight or light gauge steel frame roll forming machines, generally consists of a manual decoiler, a feeding unit, an embossing rolling tool, a roll forming unit, a cutting unit, a transmission system, a cutting unit, a hydraulic oil pump, a PLC control system and runout tables.

2. Main technical parameters of the furring channel roll forming machine

| No. | Item | Description |

| 1 | Size | 3900mm *1500mm*1600mm |

| 2 | Weight | Approx 3 Tons |

| 3 | Roller Station | 12 stations |

| 4 | Shaft | Dia 50mm |

| 5 | Shaft Material | No.45 steel, quenched, plated with chrome |

| 6 | Roller Material | No.45 steel, quenched, plated with chrome |

| 7 | Main Power | 5.5 KW |

| 8 | Hydraulic Power | 3 KW |

| 9 | Forming speed | 8~12m/min |

| 10 | Control System | Panasonic PLC control system |

| 11 | Voltage | 380V 50Hz 3Ph |

3. Main components of furring channel roll forming machine

| Name | Quantity | Units |

| Mannaul Uncoiler | 1 | Set |

| Feeding Device | 1 | Set |

| The Main Roll Forming System | 1 | Set |

| Hydraulic Device | 1 | Set |

| Hydraulic Station | 1 | Set |

| PLC System | 1 | Set |

| Receive Table | 2 | Sets |

4. Our advantages

1. We are a factory with over 10 years’ experiences in manufacturing Roll Forming Machines;

2. We have our own powerful research and development team

3. We have more than 15 technicians.

4. 5 engineers with more than 20 years of experience

5. We have advanced Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. These advanced production equipment guarantee that the good quality of each part and the appearance of our machines;

6. Our machines have reached the International Inspection Standards;