Dongguan Merrock Industry Co.,Ltd |

|

Verified Suppliers

|

|

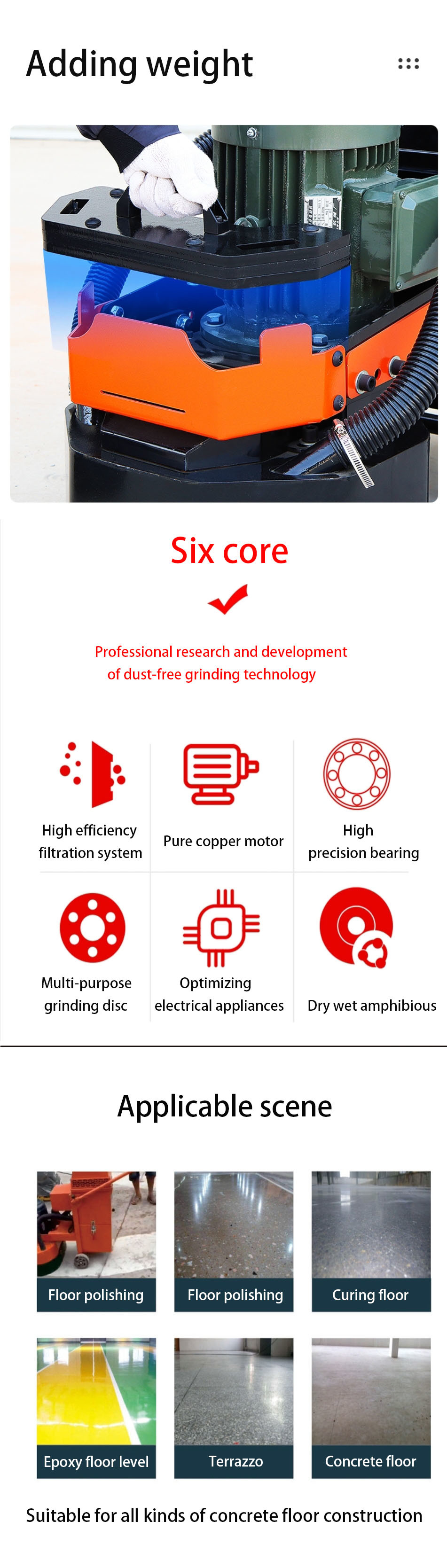

Concrete Floor Grinder With Vacuum 110V Volt Propane 480 220V

Quick Detail:

| Name | 6 heads floor polishing machine | Application | Marble, granite, terrazzo, concrete floor |

| Type | S6 Single Phase | Function | Leveling, polishing, grinding, renovating |

Description:

1. 5.5HP Single Phase Terrazzo Grinding Machine 220V Concrete Floor

Grinding Machine designed for big industrial floor area grinding

with high efficiency and competitive price

2. Beautiful and generous appearance design

3. Folding handle and integration control panel, to make operation

easy and safe

4. Big power motor with frequency conversion, to meet Frequent and

long time use requirements for industrial floor grinding

Application:

For stone leveling, stone polishing and grinding, concrete

polishing and grinding, also apply to remove the old coat of epoxy

etc...

Specification:

Name | S6 | Large grinding machine |

Type | S6-380B | S6-220B |

Voltage | 380V-440V | 220V-240V |

Motor | 7.5HP | 7.5HP / 10HP |

Inverter | 10HP | 10HP |

Speed(rpm/m) | 0-1500 Stepless speed regulation | 0-1500 Stepless speed regulation |

Body Weight | 257KGs | 257KGs |

Work Width | 730*350mm2 | 730*350mm2 |

Water tank | 30L | 30L |

Grinding Discs | 2pcs (6 discs) | 2pcs (6 discs) |

Available abrasive:

TIPS:

What is Concrete Grinder?

A concrete grinder is a machine used as a finishing tool. It levels and smooths out surfaces by the use of rotating discs engineered with abrasive diamond bits. Concrete grinders come in many different sizes and are used in various applications.

Hand-Held Concrete Grinders Walk-Behind Concrete Grinders

The selection of concrete grinder is dependent on the job to be

executed and the type of material to be removed. Major

classification of concrete grinders are hand-held grinders and

walk-behind grinders.

1. Hand-Held Concrete Grinders

Hand-held concrete grinders are used to grind concrete surfaces in corners, tight areas, and areas where pedestrian concrete grinders cannot easily reach for grinding. The grinding process creates a considerable amount of mud which is extracted by a shroud and extraction hose connected to the equipment unit.

2. Walk-Behind Concrete Grinders

The walk-back grinders are big concrete grinders unit that helps grind concrete onto the body of the floor. Large areas of concrete will be ground with these machines as they usually exist various models of walk-behind concrete grinders. The two main categories are rotary grinders and planetary grinders.

Rotary Grinders

Rotary grinders use a single large pad that spins at high speeds. Because these grinders have a higher rotational speed and are heavier, they are great for jobs that require heavy removal of surface matter. Rotary grinders can also create a better polish on concrete floors if done right.

However, because they're heavier and have high-speed rotating discs, they're often more difficult to maneuver. These grinders take more training in order to operate skillfully. Rotary grinders can often leave irregular scratch patterns in the concrete if the operator is not correctly trained.

Planetary Grinders

Instead of only using one disc like the rotary grinder, planetary grinders make use of multiple pads to get the job done. These pads spin simultaneously albeit at different speeds. Multiple discs with different abrasiveness allow a planetary grinder to remove material and finish a concrete floor at the same time.

Planetary grinders are more lightweight and easier to maneuver than the rotary grinders. Their design allows the operator to maneuver in straight lines without having to struggle. Planetary grinders work great for smaller jobs. They're ideal for jobs that don't require heavy concrete restoration.