Yuhong Group Co.,Ltd |

|

Verified Suppliers

|

|

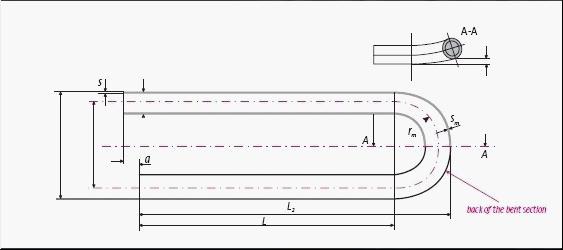

ASME SA213 TP316Ti Stainless Steel U Bend Tube 1.65mm Min Thickness

U-bends are widely used in heat exchange systems. The basis of heat exchanger equipment is

Seamless stainless steel U-tube and welded stainless steel U-bend in the key areas of strategic importance - the nuclear industry and petrochemical machinery manufacturing is crucial.

Nuclear and petrochemical machinery manufacturing.

Yuhong Special Steel has been producing U-bends since 2006 and has supplied more than 30,000 tons of stainless steel U-bends so far.

The 30,000 tons of stainless steel U-bends are sold to 35 countries.

The U-Bend Tube Comply With The Following Standards:

1. ASTM A688/ASME SA688

2. ASTM A803/ASME SA803

3. ASTM A556/ASME SA556

Technical Requirements

Straight Tubes Standard Specification For Bending:

ASME SA 213; ASME SB 163; ASME A789, ASME SA268, ASME SA269, etc.

Marking: Before Bending By Marking Machine All Over The Tube Length (Bent Section After Heat

Treatment Without Marking)

Note: Marking is also possible After Bending On The Straight Parts Of U-Bending Tube.

U-Bend Tubes:

-TEMA RCB 2.31 Standard Of The Tubular Exchanger Manufacturers Association (9th Edition).

-ASTM A688/ASME SA688 Standard Specification For Welded Tubes Of Austenitic Corrosion Resistant

Steel Grade Designed For Feed Water Boilers.

-ASTM B163/ASME SA163 Standard Techinical Requirements For Tubes Of Nickel And Nickel Alloy For

Condensers And Heat Exchangers.

-Customer Specifications.

| Corrosion Test | Conducted only when specially requested by the client |

| Chemical Analysis | Test done as per required quality standards |

| Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test | To check any evidence of air leakage |

| Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the

manufactured products supplementary testing. The tests conducted

under this include:

|

|

|