Yuhong Group Co.,Ltd |

|

Verified Suppliers

|

|

Overview:

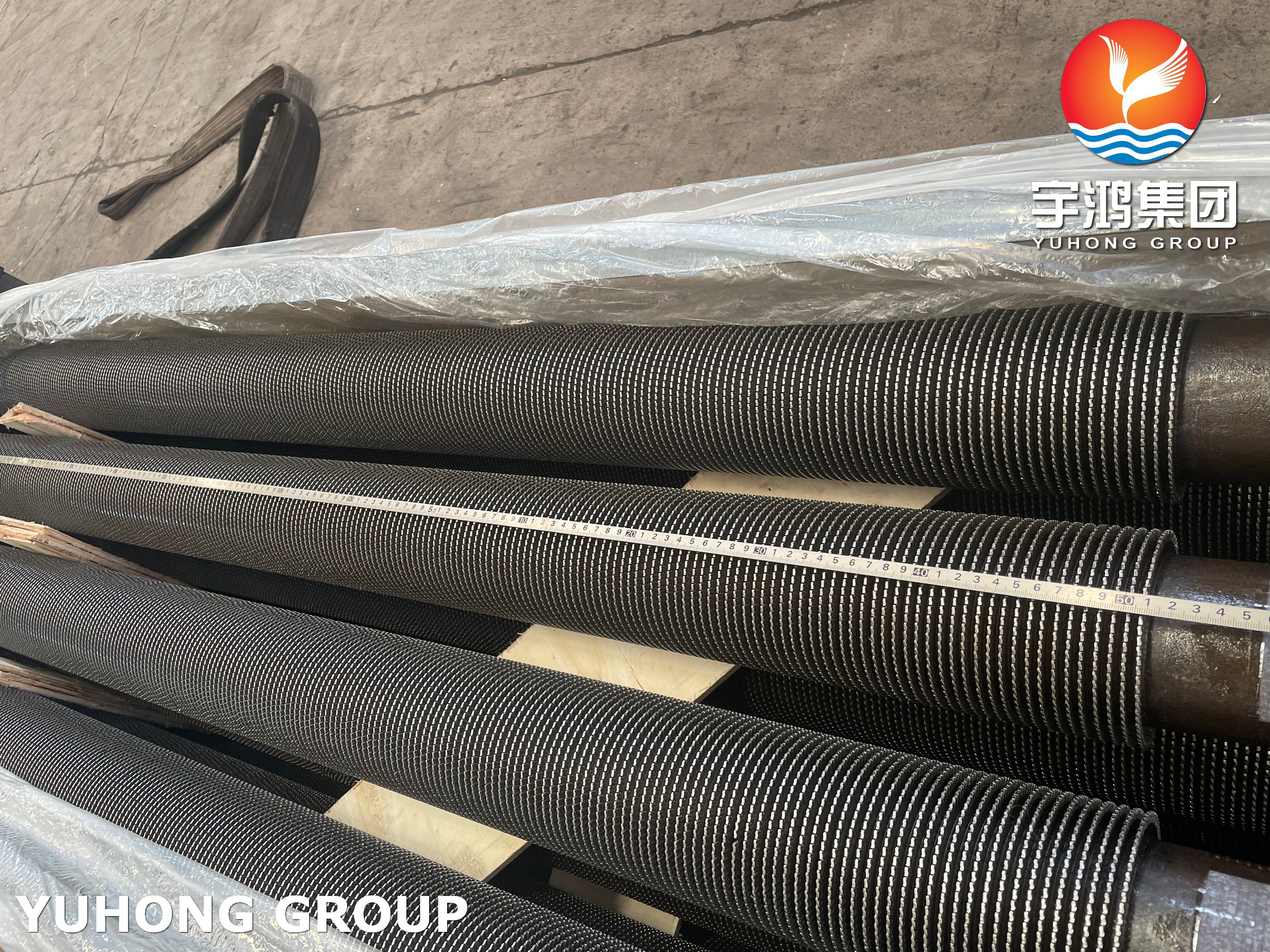

Yuhong Group's Welded Helical Serrated Finned Tubes are produced in the same manner as solid fin, except that before the fin strip is formed around the tube, the fin strip is cut (or “serrated”) crosswise from one edge (which will become the outer edge of the fin segments) to within 1/4″ of the other edge, leaving an uncut portion that will become a continuous base for the fin segmen ts.

The interval between cuts (which determines the segment width after the strip is formed around the tube) may be specified as either 5/32″ or 5/16″.

After being cut, the fin strip is held under tension and confined laterally as it is formed around the tube, thereby ensuring forceful contact with the tube surface.

As the fin strip is formed around the tube its outer (serrated) edge spreads, opening the segments like petals of a daisy. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter using Yuhong Group's unique gas metal arc welding (GMAW) process. This welding process creates the strongest fin to tube attachment in the industry, excellent heat transfer characteristics, low fin-side pressure drop and little to no change in grain microstructure and physical characteristics even when 3%-9% chromium tubes are used.

Description:

| Standard | ASTM A335 & Its equivalent ASME, DIN & EN standard |

| Base Tube Material | Gr.P9 |

| Fin Material | Carbon Steel |

| Base Tube O.D. | 1'' to 12.75'' |

| Fin Height | 0.375'' to 1.25'' |

| Fin Thickness | 20ga (.035″) to 16ga (.060″) |

| Fin Pitch | 1 to 7 fins per inch |

| Tube End | Plain Ends, Beveled Ends |

| Bare End | As customer's request |

| Weld Process | GMAW |

| Production Capacity | More than 5000 meters per day |

Chemical Composition:

| Grade | C | Mn | P | S | Si | Cr | Mo |

| P9 | 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.25-1.00 | 8.00-10.00 | 0.90-1.10 |

Mechanical Properties:

| Grade | Tensile Strength, min, ksi (MPa) | Yield Strength, min, ksi (MPa) | Elongation in 2 in. or 50mm, min (%) | Heat Treatment Temperature, min, °F(°C) | |

| Longitudinal | Transverse | ||||

| P9 | 60(415) | 30(205) | 30 | 20 | 1250(675) |

Application:

1. Heat Exchangers: These fin tubes are prevalently used in heat

exchangers to maximize the efficiency of heat transfer. The

serrated fins increase the surface area of the tube, facilitating

better heat exchange between the fluid within the tube and the

surrounding environment through convection.

2. Boilers: SA335 P9 11CR serrated fin tubes are utilized in

boilers to improve heat transfer efficiency. The serrations on the

fin tube create turbulent flow, enhancing the transfer of heat from

the hot gases to the water inside the tubing.

3. Condensers: In condenser applications, these fin tubes are

employed to facilitate the condensation of vapor into liquid form

by efficiently transferring heat away from the working fluid. The

serrated fins enable better heat dissipation, improving the overall

performance of the condenser.

4. Air Coolers: SA335 P9 11CR serrated fin tubes are also used in

air cooler units where they help in cooling a hot gas stream by

increasing the contact area between the hot gas and the cooling

medium (e.g., air). The serrated fins aid in dissipating heat

effectively, leading to efficient cooling.

5. Process Industries: These fin tubes find applications in various

process industries such as petrochemical, refinery, and chemical

plants where the efficient transfer of heat is crucial for numerous

operations like distillation, evaporation, and chemical reactions.

6. Power Plants: SA335 P9 11CR serrated fin tubes play a vital role

in power plants for heat recovery applications, such as in steam

generators, economizers, and air preheaters. They help in

maximizing energy efficiency by increasing the heat transfer rate.