Yuhong Group Co.,Ltd |

|

Verified Suppliers

|

|

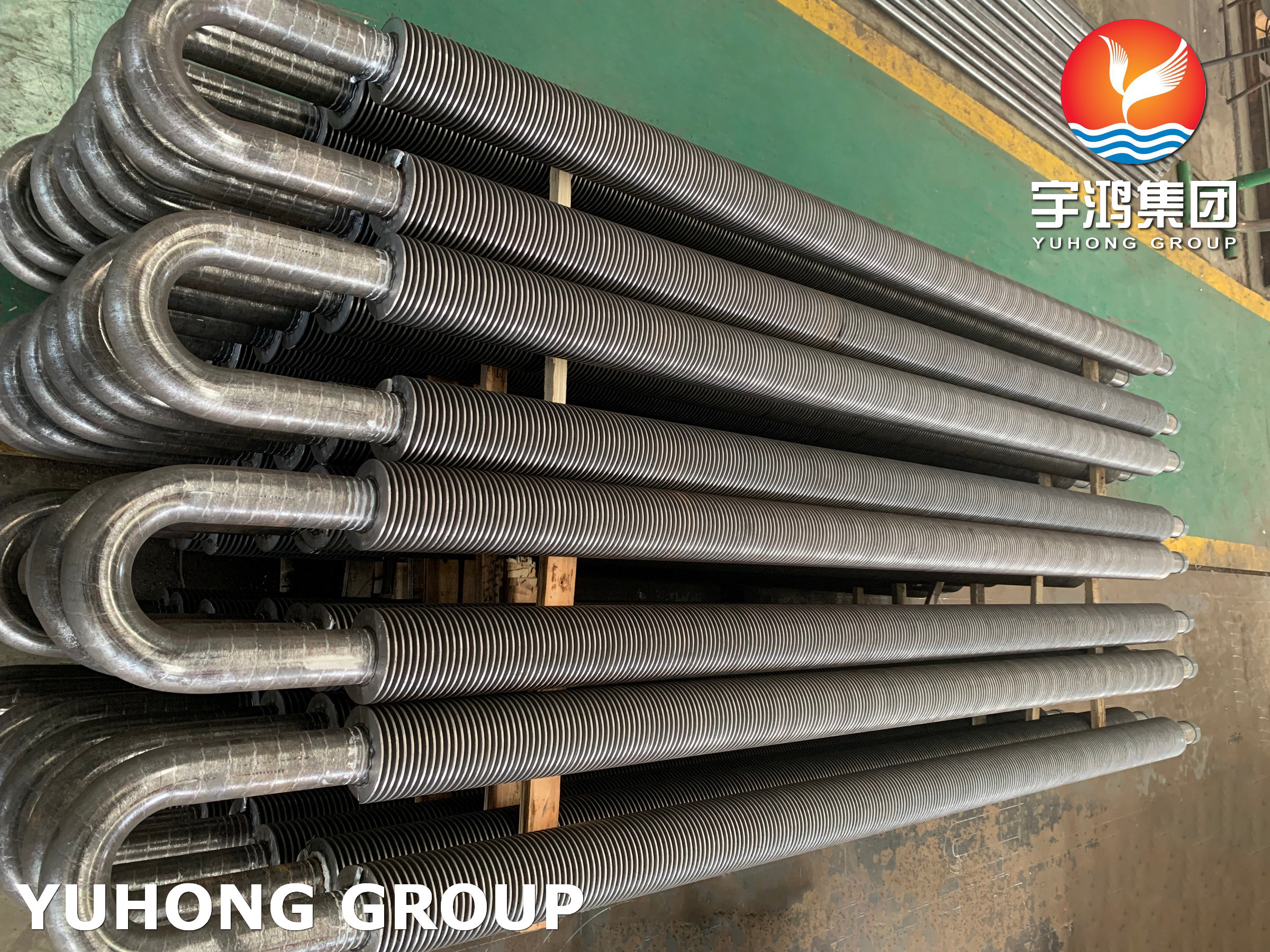

Carbon Steel A106 Gr.B HFW U Bend Fin Tube For High Pressure Service

About Fin Tube

Finned tube is a heat exchanger element. In order to improve the heat exchange efficiency, the surface area (or internal surface area) of the heat exchange tube is usually increased by adding fins on the surface of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency, such a heat exchange tube.

Performance requirement

As a heat exchange element, the fin tube works in the condition of

high temperature flue gas for a long time, such as the fin tube

used in the boiler heat exchanger has a harsh environment, high

temperature and high pressure and is in a corrosive atmosphere,

which requires the fin tube to have a high performance index.

1) Anti-corrosion performance

2), wear resistance (Anti-wear)

3), low contact resistance (lower contact resistance)

4) Higher Stability

5), anti-ash ability

High frequency welding spiral fin

High frequency spiral fin tube is one of the most widely used

spiral fin tube, and is widely used in power, metallurgy, cement

industry waste heat recovery and petrochemical industry. The high

frequency welding spiral finned tube is to heat the outer surface

of the steel strip and steel pipe until the plastic state or

melting by using the skin effect and proximity effect of high

frequency current while the steel strip is winding the steel pipe,

and weld under a certain pressure of the winding steel strip. This

high frequency welding is actually a solid phase welding. It is

more advanced than inlaying, brazing (or overall hot dip

galvanizing) methods, both in terms of product quality (fin welding

rate is high, up to 95%), and productivity and automation.

ASTM A106 is a common seamless carbon steel pipe material, its main components are carbon and iron. It is a kind of high temperature and high pressure pipeline material, widely used in oil, natural gas, chemical industry, electric power, aviation, shipbuilding and other fields.

The main features of a106 pipeline are high temperature resistance, pressure resistance, corrosion resistance, wear resistance and so on. It has excellent high temperature resistance and can withstand high temperatures of up to 600 ° C, so it is very safe and reliable to use in high temperature and high pressure environments. a106 pipeline also has good corrosion resistance, can be used in acid, alkali, salt and other corrosive media for a long time.

There are two main manufacturing processes for a106 pipeline, one is cold drawing process and the other is hot rolling process. The cold drawing process is to heat the billet to a certain temperature, and then draw the billet into a pipeline through the drawing machine. Hot rolling process is to heat the billet to a certain temperature, and then roll the billet into a pipe through the rolling machine. Each of the two processes has advantages and disadvantages, and the specific choice of the process depends on the use environment and requirements.

Pipeline a106 is a very excellent pipeline material, with good high temperature resistance, pressure resistance, corrosion resistance and other properties, widely used in various fields. During use, it is necessary to pay attention to the installation, maintenance and maintenance of the pipeline to ensure its long-term stable operation.

Chemical Composition

Chemical Composition (%) | ||||||||||

Grade | C(Max) | Mn | Si(Min) | Cu(Max) | Ni(Max) | Cr(Max) | Mo(Max) | V(Max) | P(Max) | S(Max) |

B | 0.3 | 0.29~1.06 | 0.1 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | 0.035 | 0.035 |

A106 Gr B Yield Strength

| Seamless | Grade A | Grade B | Grade C |

|---|---|---|---|

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

ASTM A106 Gr. B Pipe Application

| Food Processing Industry |

| Fabrication Industry |

| Oil and Gas Industry |

| Chemical Industry |

| Plumbing |

| General Purpose Applications |

| Heating |

| Water Supply Systems |

| Power Plant |

| Paper & Pulp Industry |