Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

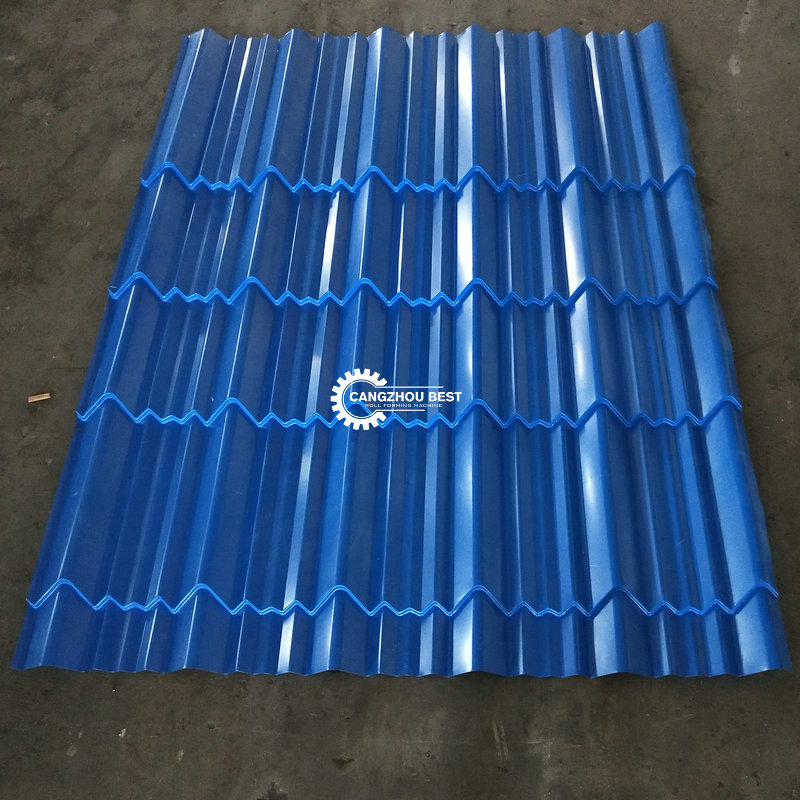

Steel Roof Sheet Deep Rib Brick Tile/Q Tile Cold Making Roll Forming Machine

Main Specifications:

1 |

Power Requirement

| Voltage | (380V 50HZ),or according client require |

| Main Motor power | 5.5kw | ||

| Cutter power | 3.0kw | ||

| 2 | Forming speed | 0-3m/min | |

| 3 | Forming stations | 13 rows | |

| 4 | Main Frame | 300H beam | |

| 5 | Sidewall thickness | 14mm | |

| 6 | Forming shaft diameter | 70mm 0.01mm-0.03mm(Grinding) | |

| 7 | Chains | 1inch chain drive | |

| 8 | Type of cutting | Roll formed and length-set cutting | |

| 9 | Control system | PLC control | |

| 10 | Install dimension(depend on the final design) | 8.0m×1.5m×1.3m | |

| 11 | Total weight (Approx) | 4.0T | |

| 12 | Roller | High grade 45# steel, hard chrome plated | |

| 13 | Feeding system | Guide type | |

| 14 | Cutting blade | Cr12 | |

| 15 | Frequency changer | Delta | |

Manual Decoiler (Hydraulic decoiler is also available)

work type: manual

usage: to support the coil and make the uncoiling

capacity: 5 tons

inner diameter: 450-550mm

coil width: 1250mm

Feeding device: With two hand wheels to adjust the feeding of the material,with bearing inside of the feeding rollers.

Machine frame: 350H steel welded

Machine structure: middle plate

Roller station: 13 stations

Roller material: 45# steel withquenched treatment and hard chroming

Shaft diameter: 70mm,solid

Shaft material: 45# steel with tempering treatment

Motor power:5.5 kw

Speed: 0-4m/min

Transmission: By chains

Voltage: 380V,50HZ,3Phase

PLC control station

PLC brand: Delta from Taiwan

Frequency converter brand: Delta from Taiwan

Encoder: Omron

Function: Automatic control the length,quantity and batch

Hydraulic cutting system

Blade material: Cr12,with quenched treatment

Motor power: 4 kw

Cutting tolerance: +/-1 mm

Cooling system: with cooling fan

Cutting type: Hydraulic cutting

Feature: Low noise and high performance

Type: Manual (Auto stacker is also available)

Length: 3 meters

Advantage of the service:

1. Provides engineering drawing design services

2.Provide machine customization service

3.Remote video service

4.Engineer on-the-spot installation service

5. Help customers booking shipping service

6.Help customers purchase raw materials service

Sales Service

1. Warranty :One year,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 35 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.