Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

Profile

Equipment Detailed Parameters:

| No. | Item | Description |

| 1 | Coil | Galvanized |

| 2 | Raw Material Thickness | 0.8 mm-2.0 mm |

| 3 | Working Speed | 8-15 m/min ( not including the cutting time) |

| 4 | Roller Station | 22 Raws |

| 5 | Dimension (L*W*H) | 13000 mm*1500 mm*1500 mm |

| 6 | Machine Weight | 9500 KG |

| 7 | Electrical Control System | Panasonic PLC (can be customized) |

| 8 | Drive Motor Power | 7.5 KW |

| 9 | Hydraulic Station Power | 5 KW |

| 10 | Power Supply | 380V, 60HZ, 3 PHASES(can be customized) |

| 11 | Cutting Accuracy | ±2 mm |

| 12 | Driving Mode | Single Chain 2 inch |

| 13 | Material of Shaft | 80 mm 45#steel forged |

| 14 | Material of Roller | 45# Steel Finish Machining, Plated Hard |

Components and Technical Specification

Manual Uncoiler

It is used to support the steel coil and realize the uncoiling by

means of rotatory movement. The steel coil is uncoiled manually.

The capacity of this uncoiler is 8 Ton, and it is capable for most

of the cases. This equipment is suitable to process the steel coils

with 508mm of ID.

Feeding Table

Put the raw material(steel plate) through the beach to manufacture

and process, it can guarantee that the products are neat, parallel

and everything is uniformity. Please refer to the equipment

regulation to know the function of locate angle iron.

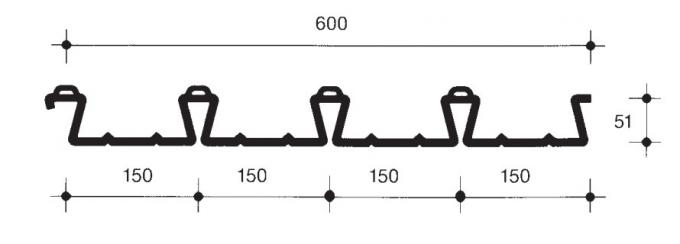

Main Roll Forming Machine

Material of rollers:45# steel,roller surfaces polishing, hard

plating , The polished surface and the heat treatment towards the

molds also can keep the molding plate surface smooth and not easy

to be marked when it is being stamped.

Hydraulic System

Power:4kw,Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the

cutter machine to begin the cutting job.

Computer Control Cabinet

The target piece`s length is adjustable and digit of it can be

adjusted. Computed mode has two modes: automatic and manual one.

The system is easy to operate and use

PLC:Delta

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the

dimension and cut the target products.Material of blades:

Cr12,quenching treatment.

Output Table

It adopts welded & screw steel and supported roller to transmit

the products,which is used to collect the finished products.

Machine loading

All machines need one 40ft container to hold.