Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

Technical Parameters:

Working Material:Galvanized Sheet(Gi),Cold Roll Steel(CRC),Hot Roll

Thickness:0.3-0.8mm

Yield Strength:235-400MPa

Decoiler:Manual/Hydraulic for Options

Side Wall Thickness:18mm

Shaft:75mm

Forming Station:20 stations

Cutter Material:Cr12 Tool Steel

Output:About 12-18 Meters Per Minute

The advantages of our shutter door machine are as follows:

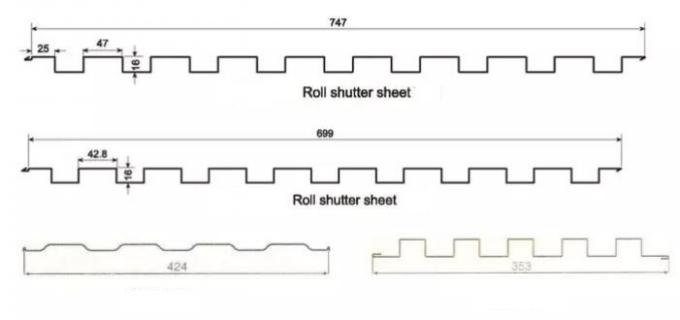

1 . Able to produce two different profiles.

2 . Save space,more convenient.

3 . Easy operation, low maintenance cost

4 . Stable and durable

Processing flow of machine:

Decoiler→ Feeding →Roll forming →Measure length →Hydraulic cutting →Exit table

We can make and design machine for composition brand, profile

drawing, manual or automatic according to customer's requirements.

Machine Parts:

1) Australian Style Rolling Shutter Door Machine pre cutter

2) Australian Style Rolling Shutter Door Machine rollers

Rollers manufactured from high quality 45# steel , CNC lathes, Heat

Treatment.

with black treatment or Hard-Chrome Coating for options.

With feeding material guide, body framemade from 400# H type steel

by welding

3) Australian Style Rolling Shutter Door Machine Scrap Coiling System

4) Australian Style Rolling Shutter Door Machine post cutter

Made by high quality mold steel Cr12 with heat treatment

Cutter frame made from high quality 20mm steel plate by welding

Hydraulic motor:2.2KW, Hydraulic pressure range: 0-16Mpa

5) Australian Style Rolling Shutter Door Machine control cabinet

6) Australian Style Rolling Shutter Door Machine occlusion device

7) Australian Style Rolling Shutter Door Machine decoiler

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and

stop

Max. feeding width: 1250mm, coil ID range 470mm±30mm

Capacity: Max. 8 Ton

With 6 tons hydraulic decoiler for option

8) Australian Style Rolling Shutter Door Machine run out table

Un-powered,one unit

Suitable for material with thickness 0.3-0.8mm

Shafts manufactured from 45#,Main shaft diameter=φ75mm,precision

machined

Motor driving,Gear chain transmission,20 steps to form

Main motor=7.5KW , Frequency speed control. Forming speed

approx.12-15m/min

Q&A:

1 . Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can

produce more than 6 kinds of panels.

2 . Do you have after sales support?

Yes, we are happy to give advice and we also have skilled

technicians available across the world.We need your machines

running in order to keep your business running.

3 . How to visit your company?

Fly to Shanghai airport: By high speed train From Shanghai(1 hour)

and get off at East Wuxi Station , then we can pick up you.

4 . What can you do if the machine broken?

Our machine's warranty period is 12 months,if the broken parts

can't repair,we can send the new parts replace the broken parts

freely,but you need pay the express cost yourself.if after warranty

period,we can through negotiation for to solve the problems,and we

supply the technical support for the whole life of the equipment.

5 . Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich

experience in transport.