Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

Aluminum Or Galvanized Steel Round Downspout Roll Forming Machine For Making Water Pipe, Rainwater

This metal gutter roll forming machine machinery is used in manufacturing steel rain gutters, and its specific dimension is made at customers' requirements. The main components of this device are decoiler, roll former, cutting device, control cabinet, and products collecting table, etc. Strips undergoes uncoiling, feeding, roll forming and then coming out the formed products. The machine is designed logically and possesses high quality forming. Controlled by PLC, this gutter roll forming machine is quite convenient to operate and debug. Roll forming part of this machine is covered by protection mesh to ensure the safety production. Keywords: roll forming machine gutter downpipe roll forming machine

Main Components of Downspout Machine

| Manual Decoiler | 1 Unit |

| Pinch Feeding | 1 Unit |

| Main Roll Forming | 1 Unit |

| Hydraulic Cutting (machine stop to cut) | 1 Unit |

| Hydraulic Station | 1 Unit |

| Electrical Control Board | 1 Unit |

| Run out Support Table | 1 Unit |

| Elbow Machine | 1 Unit |

Technical Parameters of Downspout Roll Former

| Material Spec | PPGI, Aluminum |

| Thickness of Coil Sheet | 0.4-0.6mm |

| Forming Motor Power | 7.5KW |

| Forming Speed | 0-15m/min (excluding cutting time) |

| Working Stations | About 20 Roller Stands |

| Roller Material | High grade 45#, polished and coated with 0.05mm Chrome Surface. |

| Shaft Diameter | 75mm |

| Material of Axis | High grade 45# steel |

| Voltage | 380 V, 3 Phase 50Hz ( or depend on customer’s requirement ) |

| Hydraulic Station Power | 3KW |

| Hydraulic Pressure | 10-12Mpa |

1. Type: Hydraulic uncoiler, hydraulic system for expansion

coil-inner-hole with 4 palms, electric feeding

2. Link-connect expanding system

3. Pump Power: 1.5KW

4. Load capacity: 3 Ton

5. Coil Inner Diameter: 451-530mm

5. Coil Outer Diameter: Max. 1500mm

1. Feeding section with guide;

2. Gear/Sprocket driving;

3. Rollers Station: 18 steps

4. Material of Rollers: 45# steel, CNC lathes, hard Chrome Coated

with 0.05mm

5. Diameter of Shaft: ф70mm, 45# steel

6. Main motor: 5.5 KW, Frequency speed control

7. Speed of Roll Forming: 8-12m/min

1. Cutting Type: Hydraulic Cutting, roll forming part stops when

cutting the formed products

2. Cutting Mold: 1 group

3. Material Of Cutting Mold: Cr12mov HRC 60-62

4. Cutting Length And Quantity: Clients Can Set The Length and

Quantity on the PLC Touch Screen

5. Cutting Pressure: 12-16Mpa

6. Hydraulic Station Power: 4KW

7. Tolerance Of Cutting Length: +/-2mm

1. The worker input the length and quantity of the product through

touch screen

2. Computer Control System: Panasonic PLC

3. Encoder: Omron Brand

4. Frenquency Converter: Yaskawa

5. Touch Screen: MCSG

6. Controlled System Power: Overload Protection

7. Pressure Of Hydraulic Station: ≧12Mpa

8. Current: 380V Direct Current, 50Hz, 3 Phase

1. Type: Simple Un-powered

2. Collect the product after cutting, high quality steel welded

1. A 40 feet container is required

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam

film

3. Spare parts and some small parts packed in plastic tooling box

4. All Components Fixed by steel wire with Container.

1. We strictly control the quality of raw materials and we can

offer inspection certificate of our raw materials for you.

2. We do manufacturing strictly according to the technological

processes. Besides, we carry out sampling inspection for our

products.

3. All of our workers have received relevant quality management

training so that the quality of products can be ensured.

4. Our goal is to offer the best solution for our customers, supply

high quality machine and good service with reasonable price. We

sincerely hope to cooperate with worldwide customers for mutual

success.

Main Specifications

A). Main Conponents of Downpipe Former

Decoiler ---------------------------------------------- 1 Unit

Feeding guide -------------------------------------- 1 Unit

main roll forming machine ------------------------ 1 Unit

Hydraulic Cutting device -------------------------- 1 Unit

Hydraulic Station ----------------------------------- 1 Unit

PLC computer control ----------------------------- 1 Unit

Output table ----------------------------------------- 1 Unit

Elbow machine -------------------------------------- 1 Unit

B). Working Flow of Downpipe Former

Decoiler--> Coil sheet guiding and feeding --> Roll forming

machine with safty guard--> Tighten Device -> Cut to length

--> Out-put Table --> Curving machine

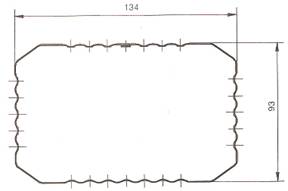

C). Main Specification of Downpipe Former

D). Applications of Downpipe Former

Rainwater downpipe, Downspout, Rainspout, Water pipe, Drainpipe

E). Competitive Advantages

1. High Quality

2. Reasonable Price

3. Good Aftersale Service

4. 1 Year Warranty

5. More Than 10 Years Experience

6. Factory Visit

F). More Machine Pictures