Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

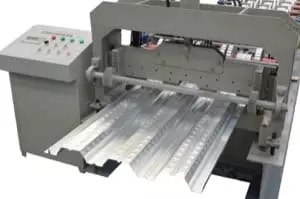

Professional Galvanized Steel Floor Decking Sheet Metal Forming Equipment High Speed 10-15m/min

Main Machinery Components of Floor Decking Sheets Production Line

| NO | Name | Quantity |

|---|---|---|

| 1. | Manual /Hydraulic Decoiler | 1 set |

| 2. | Feeding and Embossing Device | 1 set |

| 3. | Main Metal Rollforming Machine | 1 set |

| 4. | Hydraulic Cutting Device | 1 set |

| 5. | Electric PLC Control System | 1 set |

| 6. | Runout Tables | 1 set |

Technical Specifications

1 Raw Material

1). Material Thickness: 0.8-1.2mm

2). Material Type: Galvanised Steel Coils

3). Material Width: 1200mm

4). Length Cutting Tolerance: ±2mm

2 Main Cold Roll Forming Machine

1). Machine basement: 350H steel welding structure

2). Guiding device: side sliding type

3). Structure: wall panel, thickness 18mm

4). Number of stations: 35 stations

5). Main shaft material: 45# steel, O.D.: 90mm, quenching and

tempering treatment

6). Roller material: high grade 45# steel coated with chrome,

quenching 58-62℃

7). Way of drive: by chains

8). Forming speed: 10-15m/min

9). Main motor power: 11KW x 2

10). Power supply: 380V/3Phase/50HZ or designed according buyer’s

requirement

3 Hydraulic Cutter

1). Material of blade and mould: Cr12 mould steel with quenched

treatment 60-62℃.

2). Cutting system: adopt advanced hydraulic cutting system

3). Cutting type: rolling action stop, then cutting.

4 Electric Control System

1). Screen display: Mitsubishi or Siemens touching screen;

2). PLC: Mitsubishi or Siemens;

3). Measure the length automatically;

4). Count the quantity automatically;

5). Length and quantity is controlled by computer, the machine will

cut automatically according to the measured length.

6). It is easy to adjust the error of length by modification of one

parameter.

5 Runout Tables

We are suppying 2 pcs of runout tables for free and auto stacker is

also optional for sale.

Terms of Sales

| Qutation Type | FOB, CFR, CIF, C&F |

| Payment Method | 30% paid by T/T as deposit; 70% paid by T/T before the shipment |

| Delivery Time | 70 working days |

| Warranty | One year from complete production line and 10 years for rollers |

| Spare Parts Supply | Free loaded toagether with the machine |

Technical Specifications

| Coil Material | Thickness | 0.8-1.2mm |

| Coil width | 1200mm | |

| Yield Strength | 235-350Mpa | |

| Material | Galvanized Steel Rolls, GI | |

| Decoiler / Uncoiler | Coil Width | Max. 1250mm |

| I.D | 508mm | |

| O.D | Max.1200mm | |

| Coil weight | Max. 5-10 Ton | |

| Type | Manual or Electric Hydraulic | |

| Feeding Device | Pinch feeding | 1 set |

| Rollforming System | Roll Forming Line Stations | 15 sets |

| Straighten Device | 1 set | |

| Roller material | No. 45 steel coated with chrome | |

| Diameter of rolling shaft | 85mm | |

| Rolling shaft material | High grade 45# steel | |

| Drive type | Chains transmission | |

| Forming speed | around 15m/min | |

| Main power | 11KW x 2 | |

| Automatic Cutting | Cutting type | Hydraulic Cutting |

| Cutting blades material | Cr12Mov steel, HRC58-62 | |

| Length Measuring | Automatic length measuring by encoder & PLC | |

| Cutting Tolerance | +/-2mm | |

| Electric control box | PLC | Mitsubishi or Siemens |

| Frequency Inverter | Mitsubishi or Siemens | |

| Touch screen | Mitsubishi or Siemens | |

| Operation type | Touching screen & Button | |

| Hydraulic Station | Hydraulic motor power | 2.2KW |

| Function | Supply power for auto cutter | |

| Runout Tables | Table type | Unpowered (auto stacker available) |

| Function | Support the finished floor decking panels |

| Technical Details | ||

uncoiler | ||

| Loading capacity | 5T |

| Inner diameter | 470-530mm | |

| Steel coil width | 914, 1000, 1220, 1250 mm. According to your actual drawing. | |

| Working speed | 0-15m/min adjustable | |

feeding table | ||

| It is used to control the width and position of the steel sheet | |

The sheet is guided into the machine with the correct position to make sure the panel is neat and parallel. | ||

mainframe | ||

| Material | 350 H steel |

Feature | more table, no shaking | |

forming rollers | ||

| Material | High grade 45# steel. |

Roller stations | 11-16 stations. According to your actual drawing | |

cutting system | ||

| Material of blade | Cr12MOV much better than normal Cr12 material |

Hydraulic power | 3 KW | |

control cabinet | ||

| Suitable power | 380V, 50Hz, 3phase or according to your need. |

Feature | The whole process is automatically controlled by the computer. In this way, you can ensure accuracy and easy work. | |