Cangzhou Best Machinery Co., Ltd |

|

Verified Suppliers

|

|

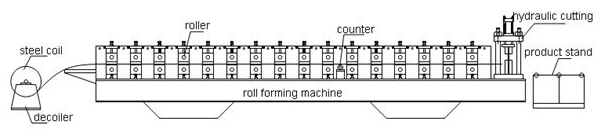

1. Main structure

a) The structure is simple and the appearance of the machine is

beautiful because we adopt the shape-steel structure and most of

the connecter is screw which make the machine flexible and

stronger.

b) All the components of machine are from brand-famous enterprise

so that they ensure the machine normal function very effectively.

c) We adopt the automatic length-fixed forming and cutting to

guarantee the length to be precise and the finished product clear

without deforming .

d) It is very easy to install the equipment and suitable for

producing in the factory.

e) Low noise with high efficiency

2. Technical Data

| Material Thickness | 0.3—0.8mm |

| Un Coiler | 3 tons manual |

| Rolling Speed | 10-15m/min |

| Roller Stations | 18 stations |

| Roller material | 45# steel, coated with chrome |

| Maim Motor Power | 7.5kw |

Hydraulic cutting Power

| 4kw |

| Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 |

| Tolerance | +-1.5mm |

| Electric Source | 380V, 50HZ,3 phase Also can satisfy customer’s require |

| Control System | PLC with touch screen |

| Way Of Drive | 1.2 inch single chain |

| No | Technical Specification | |

| 1 | Auto Uncoiler | Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand. Loading capacity:5T,Inner diameter: 500-508mm |

| 2 | Feeding Table | Put the raw material(steel plate) through the beach to manufacture and process It can guarantee that the products are neat Parallel and everything is uniformity Please refer to the equipment regulation to know the function of locate angle iron. |

| 3 | Hydraulic System Computer Control Cabinet | Power:4kw,Hydraulic oil: 40# hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. The target piece`s length is adjustable and digit of it can be adjusted Computed mode has two modes: automatic and manual one. The system is easy to operate and use PLC:EURA |

| 4 | Press Form | Press Form Material of blades: Cr12,quenching treatment |

| 5 | Shearing Mechanism | It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12,Quenching treatment |

| 6 | Auto Stacker | Start reducer quickly after finish cutting products, deliver products to hold arms by deliver rollers Then pneumatic control stack on the store table which is movable Pneumatic pump (power sources) is self supply. |

3. Our Service:

1. Installation and training of light keel making machine:

a. If buyers visit our factory and check the machine, we will teach

you how to install and use the machine,

and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to

teach you to install and operate.

C. If buyer needs our technician to go to your local factory,

please arrange board and lodging and other

necessary things.

2. After Service of light keel making machine

a. One year guarantee for whole machine.

b. 24 hours technical support by email or calling

c. If there is any problem found of light keel making machine, we

will repair it for free in one year.FAQ

4. WHY CHOOOSE US

1. Resistant to frost, heat,hail and gales; 100% waterproof, due to the lateral run-off channel on each

sheet for several models.

2. High-solid forming stand guarantees the goods and uniform high

quality of final productd

3. Precise forming, The operation automatically minimizes the

tolerance of cutting length

4. A stylish and attractive design, giving the apperance of a

traditional roof tile.

5. The raw material can be in different color, with elegant and

noble looking.

Working flow:

Packing and Shipping